Halbach Components Magnet is a category of high-performance magnetic assemblies designed and manufactured based on the Halbach array principle. These products achieve a directional concentration of magnetic flux by precisely arranging the magnetization directions of permanent magnets, enhancing the magnetic field on one side while effectively reducing it on the opposite side. Halbach Components Magnet are widely applied in motor systems, automation equipment, magnetic levitation and linear drive devices, as well as high-precision sensing and measurement equipment. They help improve magnetic field utilization, reduce energy loss, and optimize structural design.

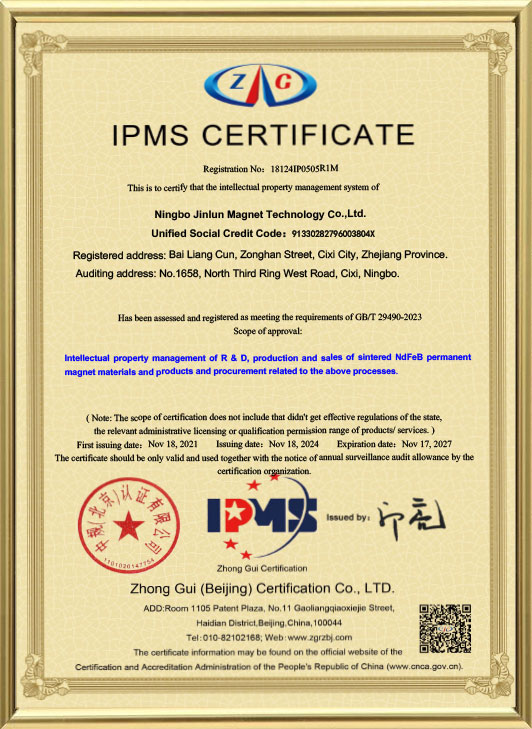

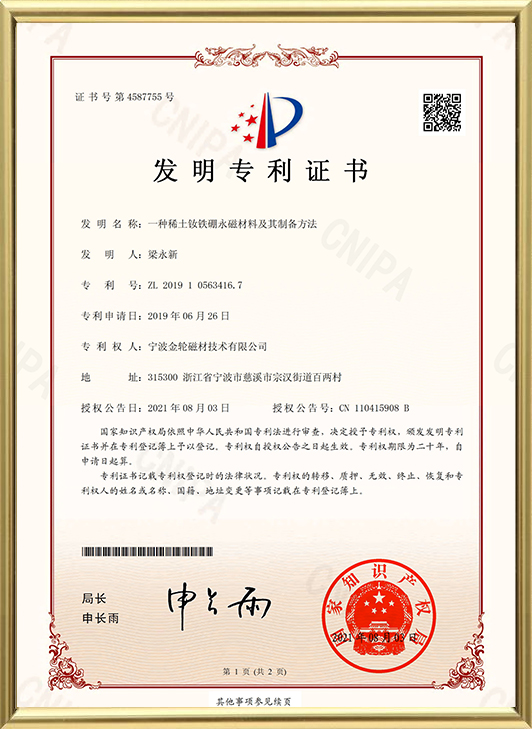

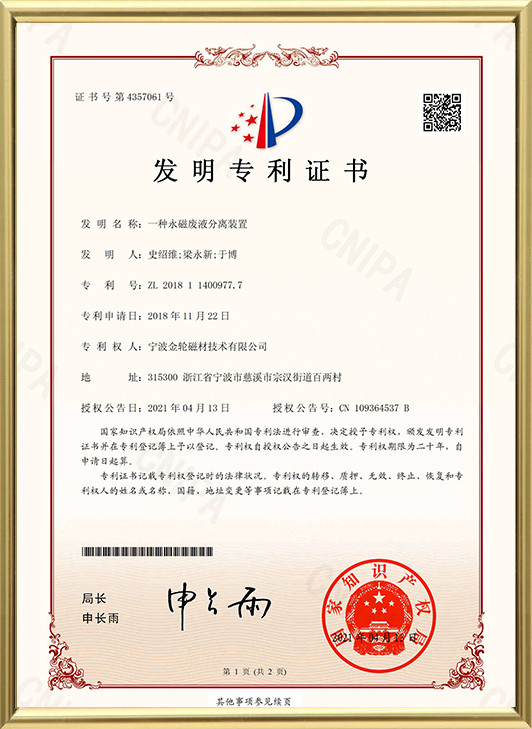

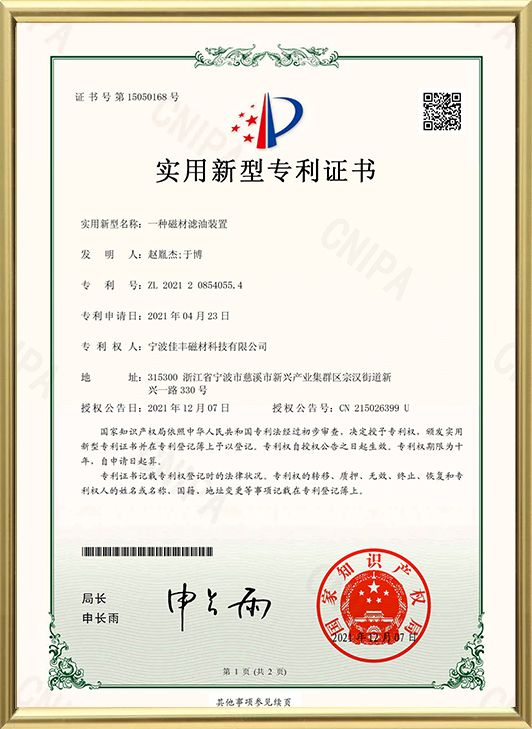

At Ningbo Jinlun Magnet Technology Co., Ltd., Halbach Components Magnet are typically produced using high-performance sintered NdFeB or other customized magnetic materials. Through precise magnetization control and assembly processes, the magnetic field distribution remains stable and consistent, meeting the industrial requirements for reliability and repeatability. Halbach Components Magnet have become an essential component in high-end magnetic system designs.

Core Applications and Functional Features

From a functional perspective, the primary purpose of Halbach Components Magnet is to enhance the effective magnetic field while minimizing wasted flux. Compared with conventional unidirectional magnets or ordinary magnetic arrays, its key functional features include:

-

Formation of a high-density, uniform, and predictable magnetic field on the working side

-

Significant reduction of leakage flux on the non-working side, minimizing magnetic interference with surrounding components

-

Increased magnetic energy efficiency, supporting lightweight and compact system designs

-

Modular design capability, facilitating integration into complex equipment

These characteristics make Halbach Components Magnet especially suitable for systems that require precise spatial, efficiency, and directional magnetic control.

Operating Principle (Halbach Array Principle)

The design of Halbach Components Magnet is based on the Halbach array principle. By sequentially rotating the magnetization direction of multiple permanent magnets, the magnetic field is enhanced on one side of the array and canceled on the other.

For example, in a linear Halbach array:

-

Adjacent magnets are oriented at 90° or other specified angles

-

Magnetic flux forms a continuous, enhanced field on the working side

-

The back side magnetic flux is weakened, reducing field leakage

In rotating systems such as motors, a ring-shaped Halbach Components Magnet can generate a more uniform radial field in the air gap, improving electromagnetic conversion efficiency. This magnetic field control method relies on the magnet arrangement itself rather than additional ferromagnetic shielding, resulting in a more efficient structural design.

Typical Equipment Types and Application Examples

1. Linear Motors and Linear Drive Systems

Halbach Components Magnet are often used in the mover or stator tracks of linear motors. Their concentrated magnetic field improves thrust density while reducing interference with guide rails and control components.

Application example: High-speed pick-and-place equipment, precision positioning platforms in automated production lines.

2. Permanent Magnet Synchronous Motors (PMSM)

In high-efficiency motor design, Halbach Components Magnet are used in rotor structures to increase air-gap flux density and reduce torque ripple.

Application example: Electric vehicle drive motors, high-speed industrial motors.

3. Magnetic Levitation and Contactless Transmission Systems

Halbach Components Magnet provide stable and directional magnetic force in magnetic levitation systems.

Application example: Magnetic levitation conveyor systems, contactless bearing structures.

4. Magnetic Field Measurement and Sensing Equipment

Due to predictable magnetic field distribution, Halbach Components Magnet are commonly used to calibrate magnetic environments.

Application example: Magnetic encoders, magnetic sensor testing platforms.

Comparison with Conventional Magnet Solutions

| Comparison Aspect | Halbach Components Magnet | Conventional Magnets / Ordinary Arrays |

|---|---|---|

| Magnetic Field Utilization | High, flux concentrated on working side | Lower, flux more dispersed |

| Leakage Flux | Significantly reduced | Noticeable leakage flux |

| Structural Efficiency | Supports compact design | Requires additional shielding or iron cores |

| Design Complexity | Higher, requires precise magnetization and assembly | Relatively simple |

| Suitable Applications | High-end, precision, and high-efficiency systems | General or low-demand systems |

This comparison highlights that Halbach Components Magnet are more suitable for applications requiring precise magnetic control and performance.

Materials and Manufacturing Considerations

Halbach Components Magnet are usually made from high-remanence, high-coercivity permanent materials to ensure stable magnetic field distribution. At Ningbo Jinlun Magnet Technology Co., Ltd., the production process emphasizes:

-

Accuracy and consistency of magnetization direction

-

Tight assembly tolerances

-

Surface treatment and protection (e.g., nickel plating, epoxy coating)

-

Magnetic performance inspection and traceability

Proper attention to these aspects directly affects the long-term performance reliability of Halbach Components Magnet.

Maintenance and Usage Guidelines

Although Halbach Components Magnet are passive magnetic components, proper handling and maintenance help extend service life:

-

Avoid strong mechanical impacts or improper disassembly

-

Prevent exposure to temperatures exceeding the magnet’s rated limit

-

Assess demagnetization risk in strong external magnetic fields

-

Regularly inspect mounting structures to prevent magnet displacement due to vibration

Standardized installation and maintenance procedures ensure long-term stability of magnetic performance in industrial systems.

Frequently Asked Questions (FAQ)

Q1: Are Halbach Components Magnet suitable for all magnetic applications?

A: They are most suitable for systems requiring magnetic field directionality and efficiency, rather than all general applications.

Q2: Can Halbach Components Magnet be customized in shape and magnetic field distribution?

A: Yes. By adjusting magnet dimensions, arrangement, and magnetization angles, customized magnetic field designs can be achieved.

Q3: Compared to a single high-performance magnet, what are the advantages?

A: The advantage lies in magnetic field distribution control and overall system efficiency, not just localized magnetic force.

As an efficient magnetic field control solution, Halbach Components Magnet play an increasingly important role in modern industrial equipment. Leveraging in-depth understanding of Halbach arrays and mature manufacturing expertise, Ningbo Jinlun Magnet Technology Co., Ltd. provides stable and controllable solutions for this category, enabling Halbach Components Magnet to serve motor systems, automation equipment, and precision devices effectively.

EN

EN English

English 中文简体

中文简体 русский

русский Deutsch

Deutsch 日本語

日本語 한국어

한국어