A Comprehensive Guide to Sintered NdFeB Magnets

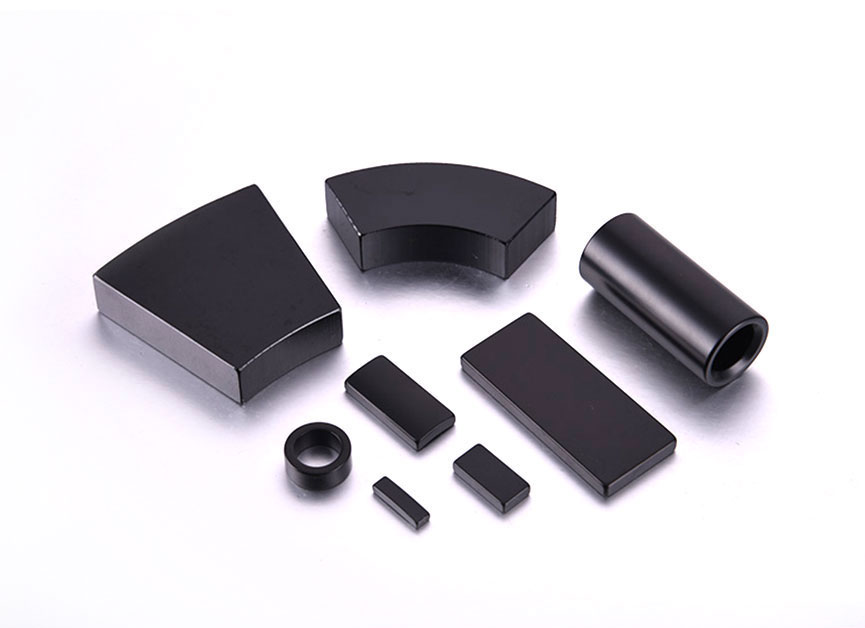

The Sintered NdFeB Magnet, also known as Neodymium Iron Boron magnet, has become one of the most powerful and widely used types of permanent magnet. Due to its exceptional magnetic properties, it has found applications in numerous industries, including automotive, electronics, renewable energy, medical devices, and more. In this article, we explore the key features of NdFeB Magnets.We also dive into the latest industry trends and provide insights into frequently asked questions.

Click to visit our products:Sintered NdFeB Magnet

What Are Sintered NdFeB Magnets?

Sintered NdFeB Magnets are made from an alloy of Neodymium (Nd), Iron (Fe), and Boron (B). The process of sintering involves heating the powdered alloy under high pressure to form a solid, compact structure. This method is particularly advantageous as it maximizes the strength of the magnets, making them ideal for demanding applications. The high magnetic energy product of NdFeB magnets allows them to produce a strong magnetic field even in relatively small sizes.

NdFeB magnets are categorized into two types: sintered and bonded. Sintered magnets, produced using the process described above, tend to be more durable and offer superior magnetic performance compared to bonded magnets, which are created by bonding the powder with a polymer or plastic material.

Key Characteristics of Sintered NdFeB Magnets

The most notable features of Sintered NdFeB Magnets are:

- High Magnetic Strength: NdFeB magnets are the strongest permanent magnets commercially available, offering a high energy product and superior magnetic field strength.

- High Coercivity: These magnets resist demagnetization, making them suitable for use in environments with varying temperatures and magnetic fields.

- Miniaturization: The compact size and high energy density of NdFeB magnets allow for miniaturization of devices and components, making them indispensable in high-tech applications.

- Thermal Sensitivity: One of the major limitations of NdFeB magnets is their susceptibility to high temperatures. Most standard NdFeB magnets lose their magnetization when exposed to temperatures above 80°C to 150°C. However, advances in material science have led to the development of high-temperature resistant NdFeB magnets, which can withstand temperatures up to 230°C.

Applications of Sintered NdFeB Magnets

The high magnetic strength of NdFeB magnets allows them to be used in a wide variety of applications across different industries:

1. Automotive Industry

In the automotive sector, NdFeB magnets are used in electric motors, sensors, and actuators. They are critical components in electric vehicles (EVs) and hybrid vehicles, where they help power electric drivetrains, regenerative braking systems, and other essential parts. The trend towards more energy-efficient vehicles continues to drive demand for these magnets, which offer significant improvements in performance and efficiency.

2. Renewable Energy

In wind turbines and solar power systems, NdFeB magnets are used to generate electricity. Their high efficiency and compact size make them ideal for converting kinetic energy into electrical power. Wind turbine generators, in particular, utilize NdFeB magnets to maximize energy output while reducing the overall size of the generator.

3. Medical Devices

NdFeB magnets play a key role in medical imaging devices such as MRI machines, as well as in hearing aids and surgical instruments. Their strong magnetic fields enable precise control and functionality in these sensitive devices.

4. Electronics and Consumer Goods

In the electronics industry, NdFeB magnets are found in speakers, hard drives, mobile phones, and headphones. Their compact size and high energy product help improve the performance and portability of consumer electronic devices.

5. Robotics and Aerospace

NdFeB magnets are increasingly used in robotics for sensors, actuators, and other components requiring precise motion control. The aerospace industry also relies on these magnets for applications in satellite systems and communication devices.

Sintered NdFeB Magnet Manufacturing Process

The manufacturing of NdFeB Magnets involves several critical steps:

- Material Sourcing: The first step involves sourcing the raw materials, primarily Neodymium, Iron, and Boron. Neodymium is the most important element for achieving the high magnetic strength of these magnets.

- Melting and Alloying: The raw materials are melted in an induction furnace to form a homogenous alloy. The ratio of Neodymium to Iron to Boron is carefully controlled to achieve the desired magnetic properties.

- Powdering: After the alloy cools, it is ground into fine powder. The size of the powder particles can influence the final magnetic performance.

- Pressing: The powder is then pressed into a mold under high pressure to form a rough magnet shape. The direction of the magnetic alignment is controlled at this stage to enhance performance.

- Sintering: The pressed magnets are then sintered in a high-temperature furnace to remove impurities and create a dense, strong structure.

- Magnetizing: The final step is magnetizing the sintered magnet by exposing it to a high magnetic field. This aligns the magnet's atomic structure, giving it its permanent magnetic properties.

NdFeB Magnet Density and Its Impact on Performance

Density is a critical factor in determining the performance of NdFeB magnets. The density of a sintered NdFeB magnet typically ranges between 7.4 to 7.8 g/cm³, depending on the exact composition and manufacturing conditions.

A higher density magnet is typically more efficient, offering greater magnetic strength per unit volume. For example, in applications like motors and generators, the higher the density, the more powerful the magnet will be in a given size. However, a higher density also leads to greater weight, which can be a disadvantage in weight-sensitive applications like aerospace and automotive industries.

In contrast, lower-density NdFeB magnets are used in applications that require reduced weight while maintaining acceptable magnetic strength. These are commonly found in consumer electronics, hearing aids, and lightweight motors.

Frequently Asked Questions (FAQs)

1. What are the advantages of using Sintered NdFeB Magnets?

NdFeB magnets offer unparalleled strength and compactness. Their high energy product allows them to produce powerful magnetic fields in small sizes, making them ideal for applications in electronics, motors, and renewable energy systems.

2. How do I select the best NdFeB Magnet Manufacturer?

Choosing the right manufacturer depends on factors such as production capacity, experience, industry expertise, and the ability to provide customized solutions. Ensure that the manufacturer meets international quality certifications such as ISO 9001 for quality assurance.

3. How does magnet density affect performance?

Higher-density NdFeB magnets typically offer stronger magnetic fields in smaller sizes, making them ideal for compact applications. However, lower-density magnets are more suitable for weight-sensitive applications where size and weight are critical considerations.

4. Are there any environmental concerns associated with NdFeB Magnets?

The production and mining of rare-earth metals like Neodymium have raised environmental concerns, particularly in relation to mining practices and the impact on ecosystems. However, manufacturers are working on sustainable alternatives, including recycling and more eco-friendly sourcing methods.

Conclusion

In conclusion, Sintered NdFeB Magnets have revolutionized the magnet industry with their exceptional strength, compact size, and versatility. Whether it's for electric vehicles, medical devices, or renewable energy applications, the role of these powerful magnets is only set to grow. As technology continues to advance, the demand for high-performance, custom-designed magnets will continue to rise, making them indispensable in a wide array of industries.

News categories

Product categories

Exhibition Information

Content

- 0.1 Click to visit our products:Sintered NdFeB Magnet

- 0.2 What Are Sintered NdFeB Magnets?

- 0.3 Key Characteristics of Sintered NdFeB Magnets

- 0.4 Applications of Sintered NdFeB Magnets

- 0.5 Sintered NdFeB Magnet Manufacturing Process

- 0.6 NdFeB Magnet Density and Its Impact on Performance

- 0.7 Frequently Asked Questions (FAQs)

- 1 Conclusion

Jinlun Magnet specialized in the research and development, production, and sales of high-performance rare-earth permanent magnet materials.

-

Sales00@jlmagnet.com

Sales00@jlmagnet.com

-

+86-574-6321 2222

+86-574-6321 2222

-

No. 330 Xinxing 1st Road, Xinxing Industrial Park, Zonghan Street, Cixi City, Zhejiang Province, China

No. 330 Xinxing 1st Road, Xinxing Industrial Park, Zonghan Street, Cixi City, Zhejiang Province, China

Mobile QR Code

Copyright © Ningbo Jinlun Magnet Technology Co., Ltd. All Rights Reserved.

China sintered NdFeB magnet manufacturer wholesale sintered NdFeB magnet factory

EN

EN English

English 中文简体

中文简体 русский

русский Deutsch

Deutsch 日本語

日本語 한국어

한국어