Sintered NdFeB Magnet and Sintered Rare Earth Magnets: A Comprehensive Guide

Sintered NdFeB magnets are some of the most powerful permanent magnets available today, made from an alloy of neodymium (Nd), iron (Fe), and boron (B). These sintered rare earth magnets are known for their strength and are widely used across various industries. This guide will delve into their properties, applications, advantages, and compare them with other types of magnets.

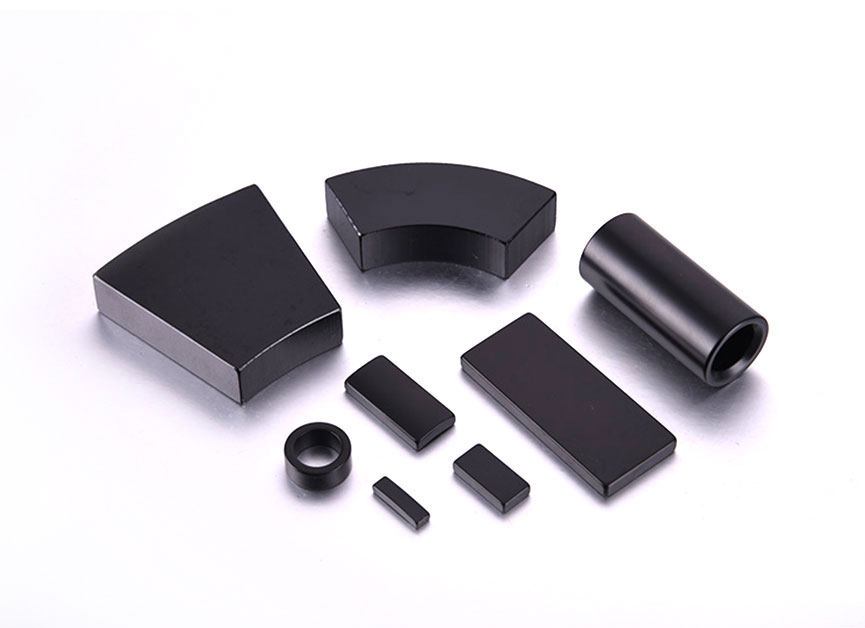

Click to visit our products:Sintered NdFeB Magnet

What is Sintered NdFeB Magnet?

The sintered NdFeB magnet is a type of rare earth magnet that is made through a sintering process. It involves heating powdered NdFeB material to form a solid magnet. This magnet is composed primarily of neodymium, iron, and boron, which gives it extraordinary magnetic strength and stability.

How Sintered NdFeB Magnets are Made

The production of sintered NdFeB magnets involves several key steps, including powder preparation, molding, sintering, and magnetization. The process begins by creating a fine powder of NdFeB alloy. This powder is then pressed into a mold and heated at a high temperature to form a solid mass. After sintering, the magnet is magnetized to its final strength. The final product is a dense, high-performance magnet capable of withstanding extreme conditions.

Key Advantages of Sintered NdFeB Magnets

- High Magnetic Strength: Sintered NdFeB magnets have a very high coercivity and remanence, making them extremely strong.

- Compact Size: Due to their high energy density, they can generate a strong magnetic field in a compact form.

- Wide Range of Applications: These magnets are used in motors, sensors, loudspeakers, and more.

- Excellent Thermal Stability: Sintered NdFeB magnets perform well even in high-temperature environments, though special coatings may be needed for optimal performance.

Applications of Sintered NdFeB Magnets

| Industry | Application | Details |

|---|---|---|

| Automotive | Electric motors, sensors, and actuators in electric vehicles. | Electric vehicles rely on strong magnets to drive motors and sensors. |

| Electronics | Speakers, microphones, and hard disk drives. | Magnets are used in motors and to enable magnetic storage. |

| Renewable Energy | Wind turbine generators and electric motors. | Used to produce and generate electricity through sustainable methods. |

| Medical | MRI machines and other medical equipment requiring strong magnets. | Critical in medical imaging and diagnostic equipment. |

What are Sintered Rare Earth Magnets?

Sintered rare earth magnets are magnets made from rare earth metals such as neodymium, samarium, and dysprosium. These magnets are known for their strength, durability, and high resistance to demagnetization. Sintered NdFeB magnets are the most common form of sintered rare earth magnets, but there are other varieties, such as samarium-cobalt (SmCo) magnets.

Comparison: Sintered NdFeB vs. Other Sintered Rare Earth Magnets

| Magnet Type | Magnetic Strength | Cost | Temperature Stability |

|---|---|---|---|

| Sintered NdFeB | Very High | Moderate | Good (can be enhanced with coating) |

| Samarium Cobalt (SmCo) | High | Higher | Excellent (better than NdFeB) |

| Sintered AlNiCo | Moderate | Low | Excellent |

Frequently Asked Questions (FAQ)

1. How do Sintered NdFeB magnets compare to ceramic magnets?

Sintered NdFeB magnets are far stronger than ceramic magnets. Ceramic magnets, made from iron oxide, are much cheaper but do not provide the same level of magnetic strength or durability as NdFeB magnets.

2. Are Sintered NdFeB magnets corrosion-resistant?

Without proper coating, sintered NdFeB magnets are susceptible to corrosion. Common coatings include nickel, zinc, and epoxy to protect the magnet from environmental damage.

3. What is the maximum operating temperature for Sintered NdFeB magnets?

The maximum operating temperature for sintered NdFeB magnets typically ranges between 80°C and 220°C, depending on the grade. However, this can vary based on the magnet’s specific alloy composition.

Conclusion

Sintered NdFeB magnets and other sintered rare earth magnets play a crucial role in modern technology, offering high-performance solutions for a range of industries. Their superior magnetic strength, compact size, and diverse applications make them indispensable in fields like automotive, electronics, renewable energy, and medical technologies.

News categories

Product categories

Exhibition Information

Jinlun Magnet specialized in the research and development, production, and sales of high-performance rare-earth permanent magnet materials.

-

Sales00@jlmagnet.com

Sales00@jlmagnet.com

-

+86-574-6321 2222

+86-574-6321 2222

-

No. 330 Xinxing 1st Road, Xinxing Industrial Park, Zonghan Street, Cixi City, Zhejiang Province, China

No. 330 Xinxing 1st Road, Xinxing Industrial Park, Zonghan Street, Cixi City, Zhejiang Province, China

Mobile QR Code

Copyright © Ningbo Jinlun Magnet Technology Co., Ltd. All Rights Reserved.

China sintered NdFeB magnet manufacturer wholesale sintered NdFeB magnet factory

EN

EN English

English 中文简体

中文简体 русский

русский Deutsch

Deutsch 日本語

日本語 한국어

한국어