Disc Permanent Magnet is one of the most widely used structural forms of permanent magnets, typically manufactured in a circular, flat shape. This type of magnet features uniform magnetic field distribution, a compact structure, and flexible installation, making it suitable for applications where space efficiency and magnetic stability are critical. Disc Permanent Magnet products are commonly used in motor systems, sensors, automation equipment, medical devices, and various precision industrial applications. As modern equipment continues to move toward higher efficiency, miniaturization, and reliability, Disc Permanent Magnet plays an essential role across multiple industries.

From a category perspective, the shared characteristics of Disc Permanent Magnet products are mainly reflected in their functional purposes, magnetic performance, and material systems. Whether applied in synchronous motors, rotating devices, or magnetic holding assemblies, the fundamental function of Disc Permanent Magnet is to provide a stable magnetic field for energy conversion, positioning, driving, or sensing.

Working Principle and Magnetic Performance

Disc Permanent Magnet relies on the stable alignment of magnetic domains within the material to generate a continuous magnetic field without the need for external power. In applications such as synchronous motors and servo systems, Disc Permanent Magnet is commonly used as the rotor magnetic source, interacting with the stator’s electromagnetic field to achieve stable speed control and high operational efficiency.

Compared with rectangular or ring-shaped magnets, Disc Permanent Magnet features a shorter magnetic flux path and higher magnetic field concentration, making it particularly suitable for designs that require axial magnetic fields or compact layouts. This structural advantage explains its widespread use in motors, encoders, and sensor systems.

Material Types and Structural Variations

Disc Permanent Magnet products are primarily manufactured using the following material systems:

-

Sintered Neodymium Iron Boron (NdFeB)

Offers high remanence, strong coercivity, and high energy product. It is widely used in synchronous motors, advanced automation equipment, and new energy vehicle systems. -

Ferrite (Ceramic Magnets)

Provides stable performance and good corrosion resistance at a relatively controlled cost, suitable for applications with moderate magnetic performance requirements and complex operating environments. -

Samarium Cobalt (SmCo)

Known for excellent thermal stability and resistance to demagnetization, commonly used in aerospace, high-temperature motors, and specialized industrial equipment.

Depending on application requirements, Disc Permanent Magnet can be customized in terms of thickness, dimensional tolerance, surface coating (such as nickel plating or epoxy coating), and magnetization direction (axial or radial).

Typical Applications and Use Cases

Disc Permanent Magnet is widely applied across various industries, including:

-

Synchronous and Servo Motors: Serving as a core magnetic source to improve efficiency and operational stability

-

Industrial Automation Equipment: Used in positioning systems, drive modules, and magnetic coupling assemblies

-

Medical and Inspection Devices: Providing stable magnetic fields for precision instruments

-

Consumer Electronics and Sensors: Supporting miniaturized designs with high response accuracy

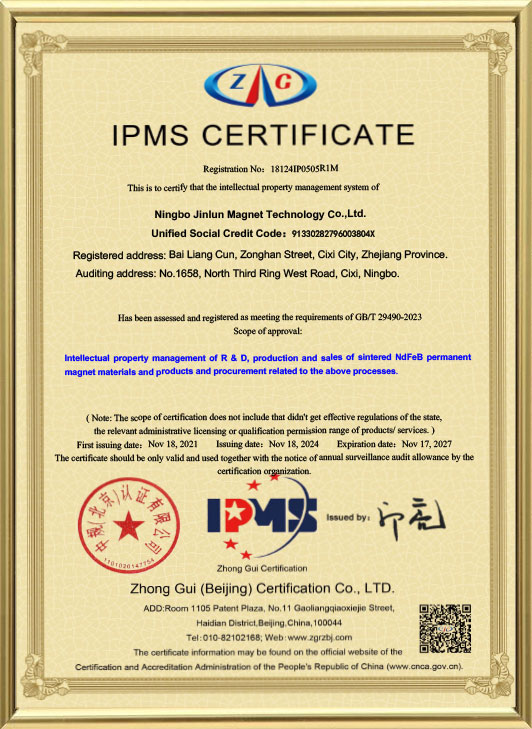

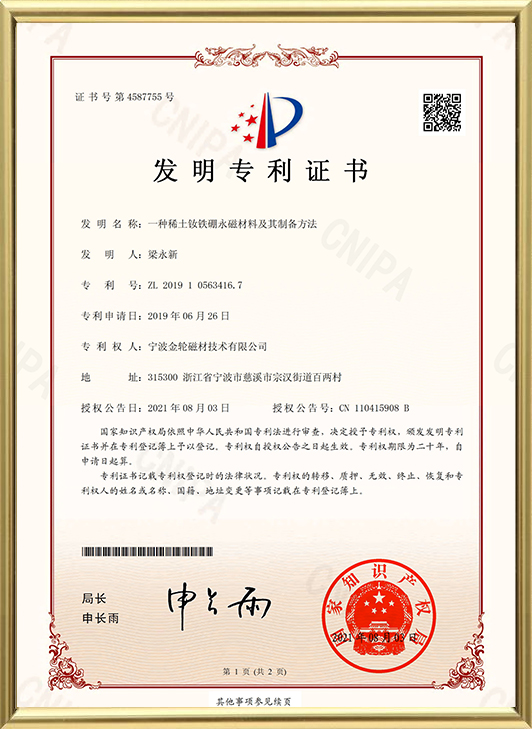

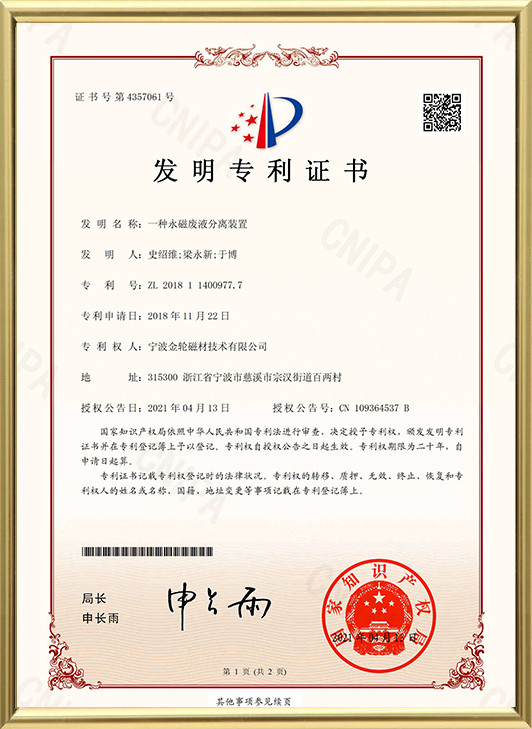

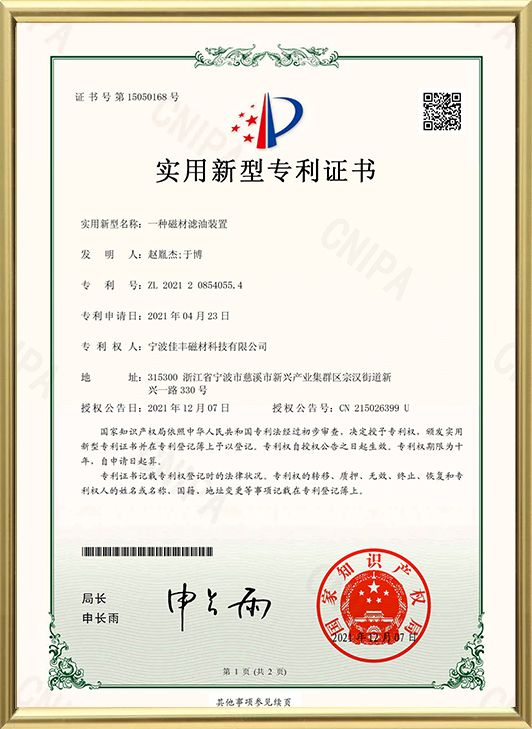

In synchronous motor applications, consistent magnetic performance of Disc Permanent Magnet helps reduce torque ripple and enhance smooth motor operation. With long-term experience in high-performance sintered NdFeB manufacturing, Ningbo Jinlun Magnet Technology Co., Ltd. supports motor manufacturers by providing Disc Permanent Magnet products with stable and repeatable magnetic properties.

Comparison with Other Magnet Shapes

| Comparison Aspect | Disc Permanent Magnet | Block / Rectangular Magnet | Ring Magnet |

|---|---|---|---|

| Magnetic Field Distribution | Uniform and concentrated | Edge field variation | Suitable for circular paths |

| Installation | Flexible, axial compatibility | Structural limitations | Higher assembly precision required |

| Typical Applications | Motors, sensors, encoders | Industrial fixation | Motor rotors |

Overall, Disc Permanent Magnet is particularly well suited for applications requiring compact design, consistent magnetic fields, and efficient assembly.

Frequently Asked Questions (FAQ)

Q1: Is Disc Permanent Magnet suitable for high-temperature environments?

Yes, depending on the material selection. SmCo and high-grade sintered NdFeB Disc Permanent Magnet can operate reliably under elevated temperatures.

Q2: Can Disc Permanent Magnet be customized in size and magnetic performance?

Yes. Diameter, thickness, tolerance, magnetization direction, and surface treatment can all be tailored to specific application requirements.

Q3: Does the magnetic strength of Disc Permanent Magnet decay over time?

Under normal operating conditions, high-quality permanent magnets experience minimal magnetic loss and maintain stable performance over long service periods.

EN

EN English

English 中文简体

中文简体 русский

русский Deutsch

Deutsch 日本語

日本語 한국어

한국어