Block Sintered NdFeB is a rectangular neodymium–iron–boron magnet produced through powder metallurgy sintering. This product category shares common characteristics such as high magnetic energy product, strong coercivity, and good dimensional stability. Its block shape is suitable for designs requiring flat contact surfaces, modular assembly, or wide-area magnetic field coverage. Block Sintered NdFeB is widely used in motors, sensors, automation equipment, and precision components, serving as a fundamental magnetic element in many systems.

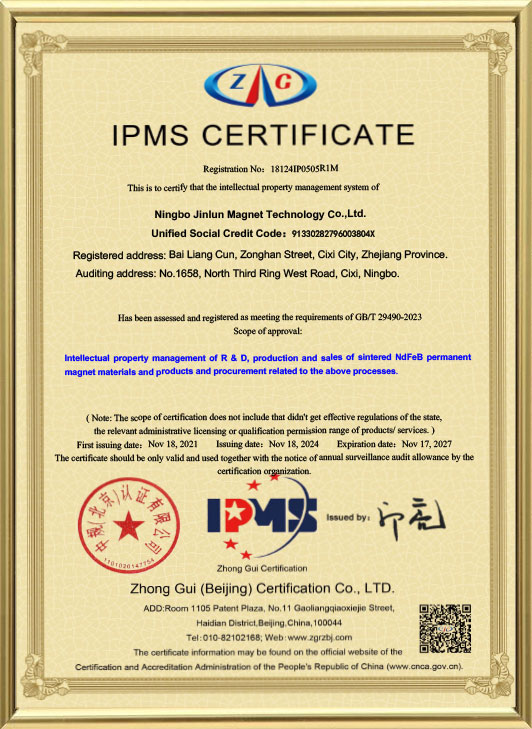

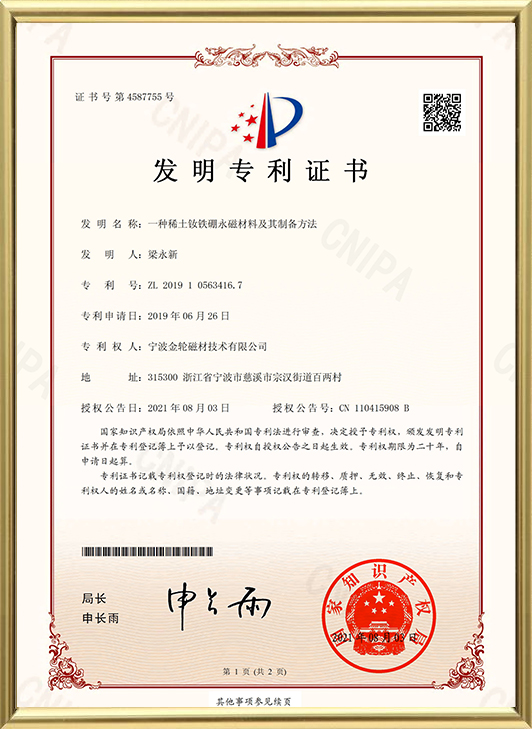

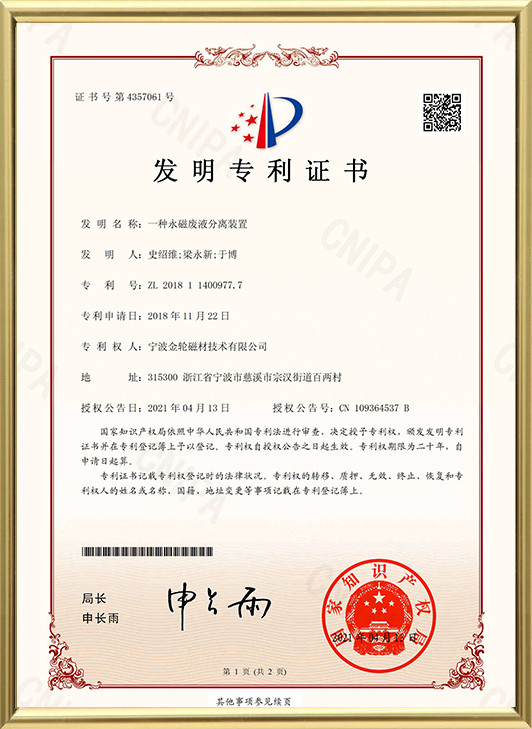

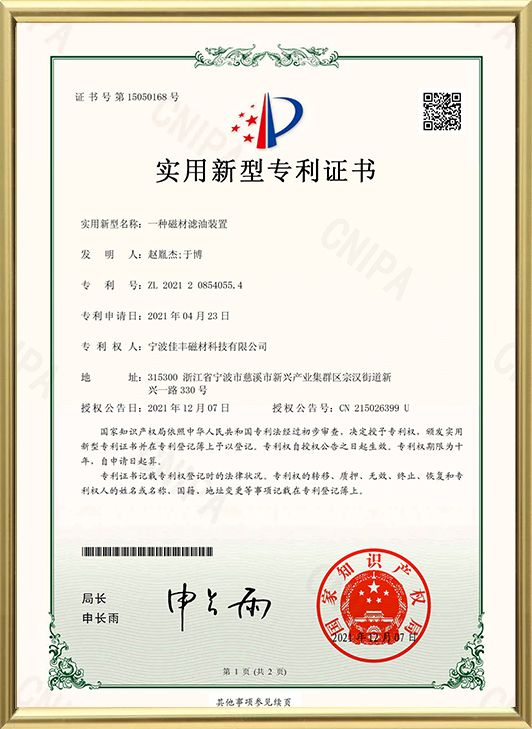

Ningbo Jinlun Magnet Technology Co., Ltd. focuses on the development and production of sintered NdFeB magnets. The company provides Block Sintered NdFeB with stable performance, various material grades, and precise machining capabilities to meet industry demands for magnetic properties, temperature resistance, and dimensional accuracy.

1. Basic Science of Block Sintered NdFeB

Working Principle

Sintered NdFeB is a rare-earth permanent magnet material. Through the alignment of magnetic domains during production, the magnet maintains strong and stable magnetic performance. Key parameters include magnetic energy product (BHmax), coercivity (Hcj), and remanence (Br).

Shape Characteristics

-

Suitable for embedding, bonding, and mechanical fastening

-

Regular cross-section, ideal for precise magnetic circuit design

-

Can be combined into arrays such as Halbach arrays

2. Industry Application Fields

Block Sintered NdFeB is applied in systems that require strong magnetic force, efficient space utilization, and stable magnetic field uniformity, such as:

-

Motors & Wind Power: Rotor–stator assemblies, magnetic flux control

-

Industrial Automation: Linear drives, lifting systems, positioning and holding mechanisms

-

Medical Equipment: Imaging devices, magnetic transmission components

-

Electronics & Consumer Devices: Speakers, magnetic mounts, magnetic sensing parts

-

Transportation: Rail systems, magnetic levitation components

-

Magnetic Separation & Industrial Sorting

3. Key Selection Criteria

When choosing Block Sintered NdFeB, consider the following factors:

-

Magnetic Grade (N35–N52 / H, SH, UH, EH high-temperature grades)

Defines the required magnetic strength and working stability. -

Operating Temperature

Select a suitable temperature grade based on system heat conditions to avoid demagnetization. -

Dimensions and Tolerances

Requirements for flatness, perpendicularity, and thickness vary by industry. -

Coating & Protection

Common coatings: NiCuNi, Zinc, Epoxy, Gold

Environmental conditions determine the appropriate corrosion protection level. -

Magnetization Direction

Such as through-thickness or through-width, crucial for magnetic circuit design.

4. Comparison With Other Magnet Types

| Item | Block Sintered NdFeB | SmCo | Ferrite |

|---|---|---|---|

| Magnetic Energy | High | Medium | Low |

| Temperature Resistance | Medium–High (by grade) | High | Medium |

| Cost | Medium | High | Low |

| Typical Use | High-performance and compact designs | High-temperature or harsh environments | Cost-sensitive applications |

Block Sintered NdFeB generally offers higher magnetic force per volume, suitable for compact devices requiring strong magnetic performance.

5. Industry Trends & Material Development

-

Trend 1: Increasing use of high-temperature materials

-

Trend 2: Reduction of heavy rare-earth elements while maintaining coercivity

-

Trend 3: More automated machining for improved dimensional consistency

-

Trend 4: Wider adoption of high-performance Block Sintered NdFeB for magnetic circuit optimization

Ningbo Jinlun Magnet Technology Co., Ltd. continues to optimize powder formulation and production processes to improve the stability, consistency, and precision of Block Sintered NdFeB to meet growing market demand for high-performance magnets.

6. FAQ

1. What is the difference between Block Sintered NdFeB and a regular block magnet?

Block Sintered NdFeB refers specifically to magnets made from sintered neodymium–iron–boron, with customizable performance and temperature grades suitable for industrial applications.

2. Can the magnets be produced according to a drawing?

Yes. Dimensions, tolerances, chamfers, holes, and magnetization directions can be customized according to technical drawings.

3. How to choose the correct coating?

-

Indoor environment: NiCuNi, Zinc

-

High humidity or corrosion-prone environments: Epoxy

-

Special applications: Gold plating or special coatings

4. Can Block Sintered NdFeB be used long-term?

Yes, as long as it operates within the designed temperature range and uses appropriate corrosion protection.

EN

EN English

English 中文简体

中文简体 русский

русский Deutsch

Deutsch 日本語

日本語 한국어

한국어