Arc Permanent Magnet refers to permanent magnets manufactured with a curved or arc-shaped geometry, primarily designed to match the circular structure of motor rotors or rotating magnetic systems. This shape allows Arc Permanent Magnet products to closely follow the rotor circumference, improving magnetic flux utilization and reducing air-gap losses. As a result, Arc Permanent Magnet is widely used in synchronous motors, brushless DC motors, servo motors, and other rotating electrical equipment.

Across this category, Arc Permanent Magnet products share common characteristics in functional purpose, magnetic performance, structural design, and application focus. Their primary function is to provide a stable and efficient magnetic field within rotating systems, contributing to torque generation, speed stability, and overall energy efficiency. Due to these characteristics, Arc Permanent Magnet plays a critical role in modern motor technology, especially where compact design and high power density are required.

Working Principle of Arc Permanent Magnet in Equipment

In motor applications, Arc Permanent Magnet is typically mounted on or embedded within the rotor. Its curved geometry ensures close conformity with the stator inner diameter, allowing the magnetic field to be evenly distributed along the air gap. When the stator windings are energized, the interaction between the electromagnetic field and the magnetic field generated by the Arc Permanent Magnet produces rotational torque.

Compared with flat or block-shaped magnets, Arc Permanent Magnet enables more uniform magnetic flux distribution, which helps reduce torque ripple, vibration, and noise in motor operation. This working principle is particularly important in synchronous motors and precision drive systems.

Material Types and Manufacturing Characteristics

Arc Permanent Magnet products are manufactured using several mature permanent magnet material systems, selected according to performance requirements and operating conditions:

-

Sintered NdFeB (Neodymium Iron Boron)

Provides high remanence, strong coercivity, and high energy product. It is commonly used in high-efficiency synchronous motors, electric vehicles, and industrial automation systems. -

Ferrite (Ceramic Magnets)

Offers stable magnetic performance and good corrosion resistance at a controlled cost, suitable for motors with moderate performance requirements. -

Samarium Cobalt (SmCo)

Features excellent thermal stability and resistance to demagnetization, often used in high-temperature or high-reliability motor applications.

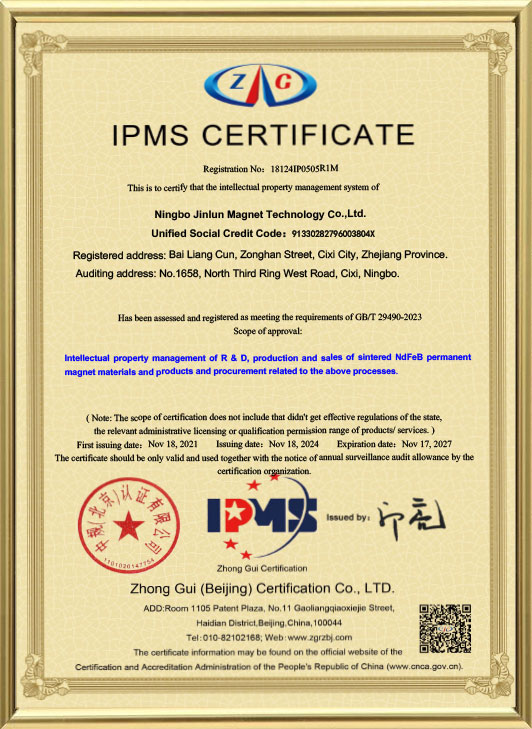

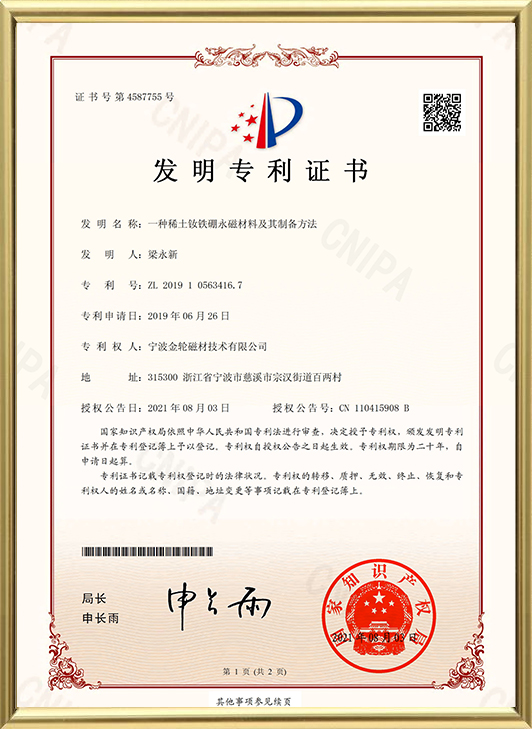

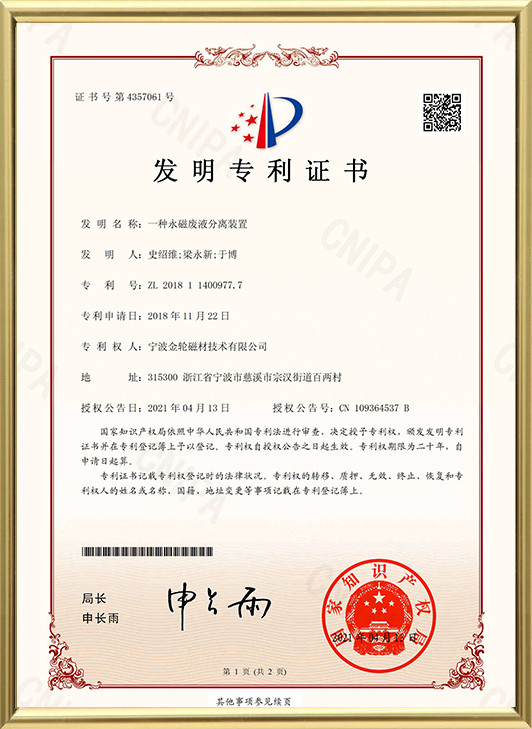

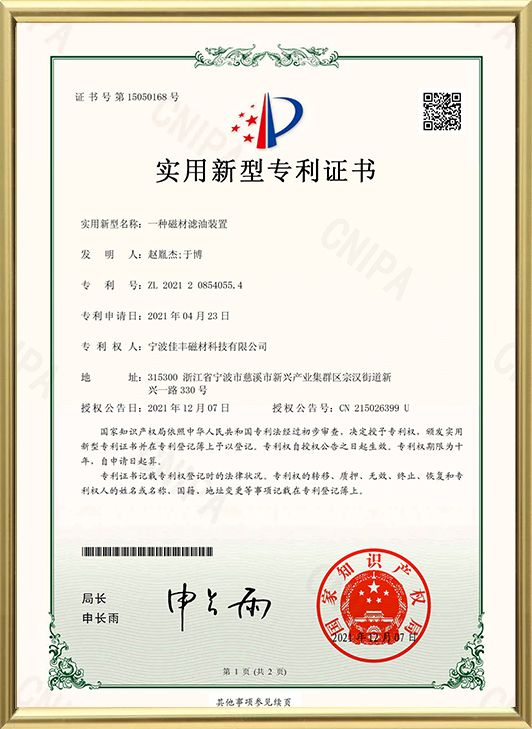

For Arc Permanent Magnet products, dimensional accuracy, arc angle consistency, and magnetization direction (radial or parallel) are critical factors. Ningbo Jinlun Magnet Technology Co., Ltd., with long-term experience in sintered NdFeB manufacturing, supports customized Arc Permanent Magnet solutions for motor-oriented applications, ensuring stable magnetic performance and dimensional consistency.

Typical Applications and Equipment Use Cases

Arc Permanent Magnet is widely applied in the following equipment and systems:

-

Synchronous Motors: Used as rotor magnets to improve efficiency, torque density, and speed control accuracy

-

Brushless DC Motors (BLDC): Enables smooth rotation and reduced cogging torque

-

Servo Motors: Supports precise positioning and dynamic response

-

Electric Vehicle Drive Systems: Contributes to compact motor design and energy efficiency

In practical applications, consistent magnetic properties of Arc Permanent Magnet help extend motor service life and maintain stable performance under continuous operation.

Application-Oriented Comparison of Magnet Shapes

| Comparison Aspect | Arc Permanent Magnet | Block Magnet | Ring Magnet |

|---|---|---|---|

| Structural Fit | Matches rotor curvature | Limited conformity | Continuous circular shape |

| Magnetic Flux Utilization | High | Moderate | High |

| Assembly Method | Segmented rotor mounting | Surface mounting | Integral mounting |

| Typical Applications | Synchronous motors, BLDC motors | Fixed magnetic systems | Encoders, motors |

Arc Permanent Magnet is especially suitable for segmented rotor designs, where multiple arc segments form a complete magnetic ring.

Key Performance Characteristics

-

Optimized magnetic flux distribution

-

Reduced air-gap magnetic loss

-

High torque density in rotating systems

-

Flexible customization of arc angle, thickness, and length

These shared features define the overall technical value of the Arc Permanent Magnet category.

Frequently Asked Questions (FAQ)

Q1: Why are Arc Permanent Magnet products commonly used in motors instead of block magnets?

Arc Permanent Magnet provides better conformity to rotor geometry, resulting in more uniform magnetic fields and improved motor efficiency.

Q2: Can Arc Permanent Magnet be customized for different motor designs?

Yes. Parameters such as arc angle, inner and outer radius, thickness, magnetization direction, and surface coating can be customized according to motor requirements.

Q3: What magnetization methods are used for Arc Permanent Magnet?

Common magnetization methods include radial magnetization and parallel magnetization, depending on motor structure and magnetic circuit design.

EN

EN English

English 中文简体

中文简体 русский

русский Deutsch

Deutsch 日本語

日本語 한국어

한국어