NdFeB magnets for magnetic applications are high-performance permanent magnets widely applied across industrial, scientific, and commercial systems. Composed of neodymium (Nd), iron (Fe), and boron (B), these magnets deliver high remanence, coercivity, and energy density, making them suitable for applications that require compact size, high efficiency, and reliable magnetic performance.

Applications and Device Principles

-

Magnetic Separation Equipment

-

Principle: NdFeB magnets generate strong magnetic fields to attract and remove ferromagnetic particles from bulk materials. This ensures product purity and improves process efficiency.

-

Application Case: Recycling plants use magnetic drum separators with NdFeB magnets to separate metals from plastics, while mineral processing facilities employ overband magnets for ore refinement.

-

Maintenance Guidance: Clean magnetic surfaces regularly to maintain separation efficiency. Inspect for mechanical damage and ensure magnetic field strength remains consistent.

-

-

Electric Motors and Generators

-

Principle: NdFeB magnets provide strong, stable magnetic fields that interact with electrical currents to produce rotational motion in motors or induce electricity in generators.

-

Application Case: Brushless DC motors in automation equipment, wind turbine generators, and high-speed industrial motors utilize NdFeB magnets to achieve high torque and efficiency.

-

Maintenance Guidance: Maintain operating temperature within rated limits. Use protective coatings to prevent corrosion and inspect for structural integrity to prevent magnet cracking under vibration.

-

-

Magnetic Sensors and Instrumentation

-

Principle: NdFeB magnets create a stable reference field for position, speed, and rotation sensors, allowing precise detection and control.

-

Application Case: Hall effect sensors, rotary encoders, and magnetic flow meters rely on NdFeB magnets for accurate measurement in industrial automation and instrumentation.

-

Maintenance Guidance: Avoid mechanical shocks and exposure to high temperatures. Periodically recalibrate sensors to maintain measurement accuracy.

-

-

Actuators and Magnetic Couplings

-

Principle: NdFeB magnets in actuators convert magnetic energy into mechanical movement, while magnetic couplings transmit torque without direct contact.

-

Application Case: Precision robotic arms, industrial valves, and fluid pumps use NdFeB-based actuators for high-speed response and contactless torque transmission.

-

Maintenance Guidance: Ensure correct alignment and avoid external demagnetizing fields. Inspect magnet coatings to prevent wear and maintain coupling efficiency.

-

Comparisons with Other Magnetic Materials

| Feature | NdFeB Magnets | Ferrite Magnets | AlNiCo Magnets | SmCo Magnets |

|---|---|---|---|---|

| Maximum Energy Product | 35–55 MGOe | 3–5 MGOe | 5–10 MGOe | 20–32 MGOe |

| Coercivity | High | Medium | Low | Very High |

| Temperature Stability | Moderate (enhanced with coatings/alloying) | High | Very High | Excellent |

| Typical Applications | Motors, sensors, separation equipment, actuators | Low-cost industrial tools | High-temperature instruments | Aerospace, high-temperature motors |

NdFeB magnets offer higher energy density and smaller size compared to ferrite and AlNiCo magnets, allowing more compact designs and higher system efficiency. While SmCo provides better thermal stability, NdFeB magnets are often preferred in magnetic applications where size and field strength are critical.

Maintenance and Handling Considerations

-

Environmental Control: Avoid exposure to moisture, corrosive chemicals, and temperatures beyond the magnet’s rated limits.

-

Mechanical Protection: NdFeB magnets are brittle and prone to chipping; handle carefully and use protective casings where necessary.

-

Demagnetization Prevention: Keep away from strong external magnetic fields and ensure proper installation in assemblies to maintain field stability.

FAQ

-

Q: Can NdFeB magnets be used in high-speed motors and industrial automation?

A: Yes, their high energy density and stability make them ideal for compact, high-efficiency motors and automation equipment. Thermal management is essential to maintain performance. -

Q: How do NdFeB magnets compare with ferrite magnets in magnetic separation?

A: NdFeB provides stronger fields and smaller designs, while ferrite is larger and less efficient but lower cost. Selection depends on process requirements. -

Q: What is the typical operational lifespan of NdFeB magnets in industrial applications?

A: With proper protection, NdFeB magnets can maintain performance for 10–15 years or longer, depending on temperature, mechanical stress, and environmental exposure. -

Q: Are NdFeB magnets suitable for contactless torque transmission?

A: Yes, when used in magnetic couplings or actuators, NdFeB magnets efficiently transmit torque without wear, provided alignment and environmental controls are observed.

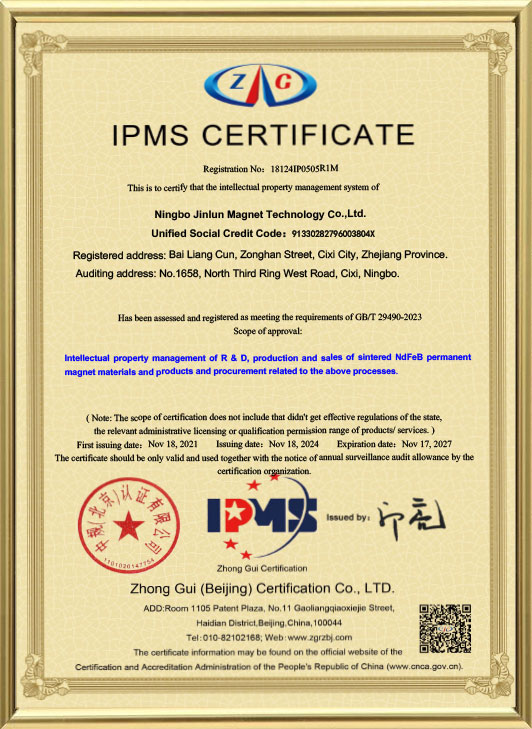

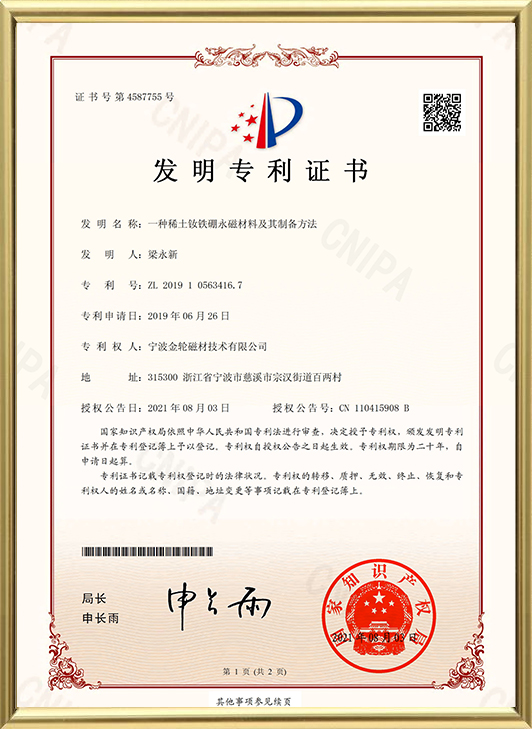

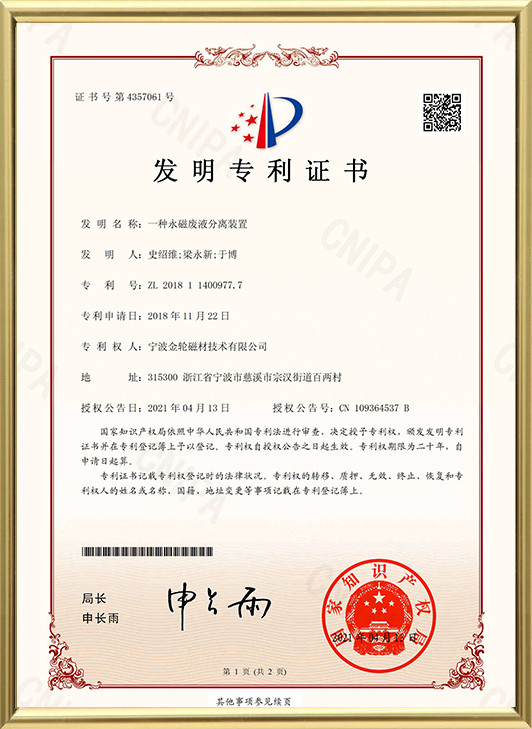

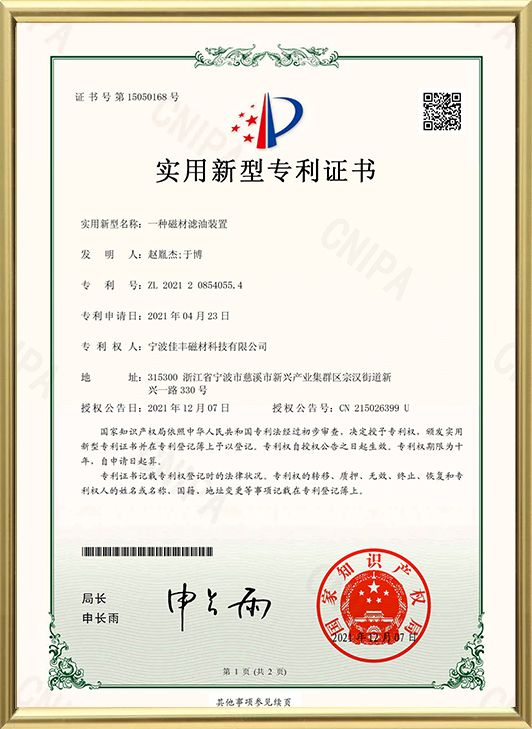

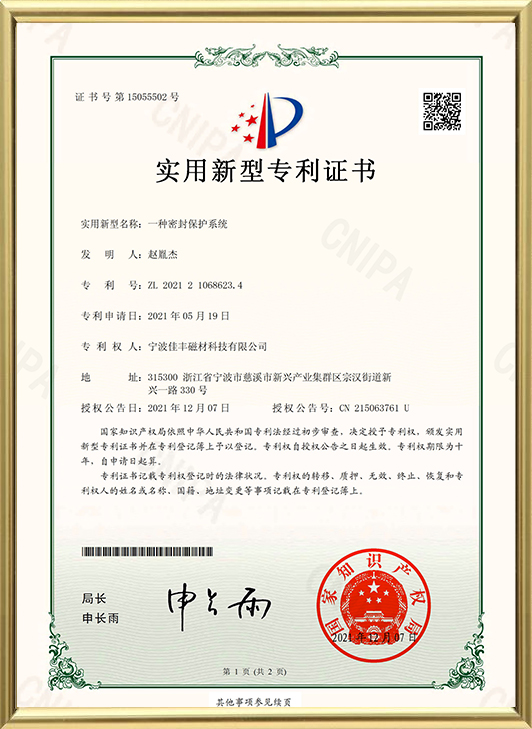

Ningbo Jinlun Magnet Technology Co., Ltd. manufactures high-performance NdFeB magnets for a wide range of magnetic applications. Leveraging over 30 years of experience and advanced international production equipment, Jinlun Magnet ensures precise magnetic properties, consistent quality, and reliable performance for industrial motors, magnetic separation systems, sensors, actuators, and more.

EN

EN English

English 中文简体

中文简体 русский

русский Deutsch

Deutsch 日本語

日本語 한국어

한국어