Sintered NdFeB Magnets for Consumer Electronics are high-performance permanent magnets designed to meet the demands of compact, efficient, and high-precision electronic devices. These magnets are produced using a sintering process that ensures high remanence, high coercivity, and excellent dimensional stability, making them suitable for applications where strong magnetic fields are required in small form factors.

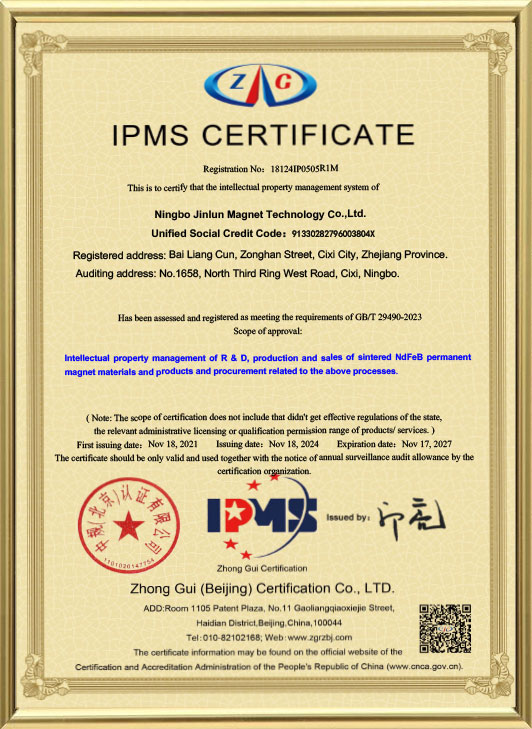

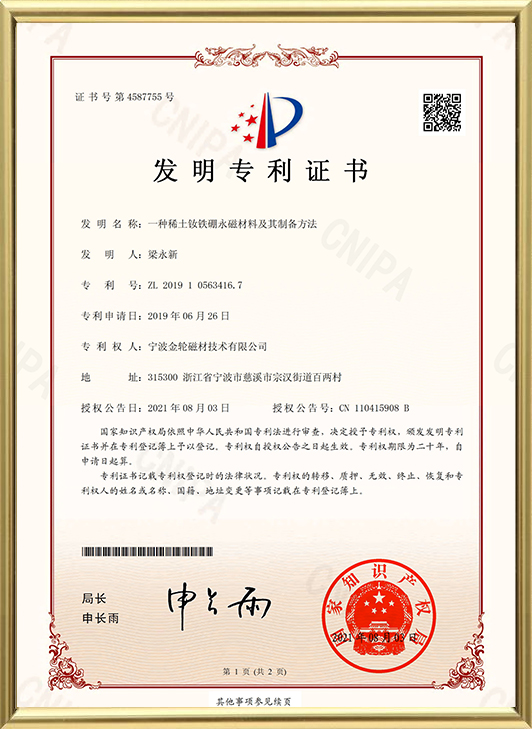

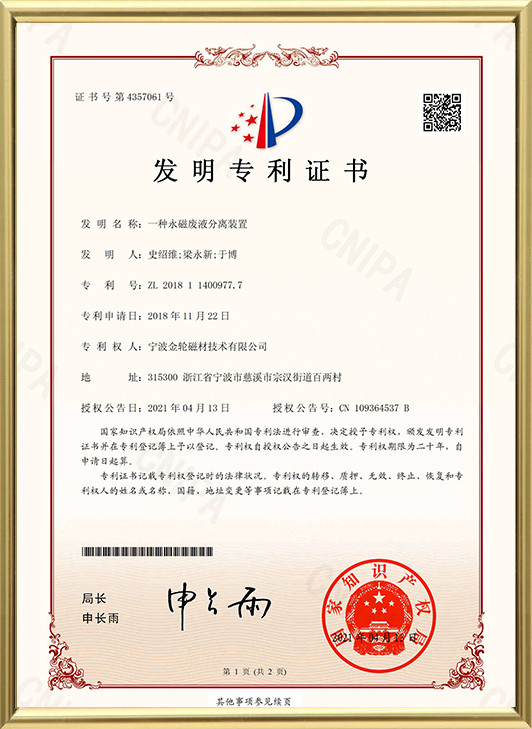

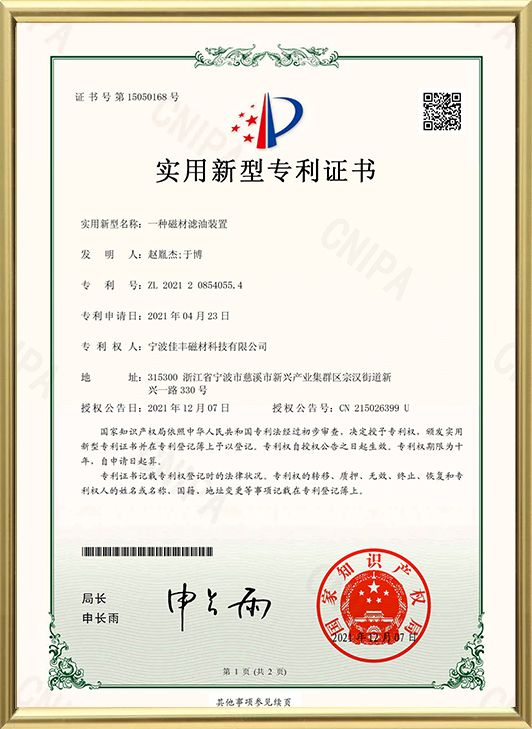

At Ningbo Jinlun Magnet Technology Co., Ltd., these magnets are manufactured using advanced international production equipment and rigorous quality control procedures. With over 30 years of experience, the company provides consistent magnetic performance, precise dimensions, and reliable supply for consumer electronics applications.

Core Functions and Features

Sintered NdFeB Magnets for Consumer Electronics share several key characteristics:

-

High Magnetic Strength: Enables miniaturization of devices while maintaining sufficient magnetic force.

-

Compact Size: Suitable for small, integrated components such as motors, actuators, sensors, and speakers.

-

Thermal and Mechanical Stability: Maintains performance under varying temperature and operational conditions.

-

Precise Tolerances: Sintered manufacturing ensures uniformity and repeatability across batches.

-

Long-Term Reliability: High coercivity reduces demagnetization risk from external magnetic fields or mechanical stress.

These features make them essential for modern consumer electronics that require efficiency, reliability, and precision in a compact form factor.

Operating Principles in Consumer Electronics

Sintered NdFeB Magnets are commonly used in devices that rely on magnetic interactions to perform mechanical or sensing functions:

-

Micro Motors: Magnets generate torque in small DC or brushless motors.

-

Speakers and Audio Devices: Magnets interact with voice coils to produce sound.

-

Sensors and Actuators: Magnetic fields allow position detection, motion control, or haptic feedback.

-

Data Storage Devices: Magnets are used in small-scale magnetic actuators or motors for disk drives.

The high remanence and coercivity of Sintered NdFeB Magnets ensure stable magnetic fields, enhancing performance and efficiency in compact electronic components.

Typical Applications and Examples

1. Smartphone Motors and Haptics

Small, high-strength magnets enable vibration motors and haptic feedback systems in smartphones.

2. Compact Audio Devices

Used in speakers, earphones, and miniature sound transducers to produce high-quality sound in limited space.

3. Consumer Robotics and Drones

Magnets provide precise torque in small motors for drones, robotic toys, and household robots.

4. Hard Drives and Storage Systems

High-performance NdFeB magnets are used in voice coil actuators to position read/write heads accurately.

5. Wearable Electronics

Magnets support compact motorized components and sensors in smartwatches, fitness trackers, and medical devices.

Comparison with Other Magnet Types

| Aspect | Sintered NdFeB Magnets | Ferrite Magnets | Bonded NdFeB Magnets |

|---|---|---|---|

| Magnetic Strength | Very high | Low | Moderate |

| Size Efficiency | Excellent for miniaturization | Poor | Moderate |

| Thermal Stability | Good (depending on grade) | Moderate | Low |

| Coercivity / Demagnetization Resistance | High | Low | Moderate |

| Manufacturing Precision | High | Low | Moderate |

| Cost | Higher | Low | Moderate |

| Typical Use | High-performance compact devices | Low-cost electronics | Cost-sensitive or complex shapes |

Sintered NdFeB Magnets provide superior performance in miniaturized, high-efficiency consumer electronics where strength, precision, and reliability are critical.

Materials and Manufacturing Considerations

Sintered NdFeB Magnets for consumer electronics are produced using a powder metallurgy sintering process:

-

Powder Preparation: High-purity Nd, Fe, B, and alloy elements are processed into fine powders.

-

Compaction: Pressed into precise shapes using high-precision dies.

-

Sintering: High-temperature sintering forms a dense, uniform microstructure.

-

Magnetization: Magnets are magnetized according to device specifications.

-

Surface Coating: Corrosion-resistant coatings such as Ni-Cu-Ni or epoxy improve durability.

At Ningbo Jinlun Magnet Technology Co., Ltd., strict quality control ensures uniform magnetic properties and dimensional accuracy suitable for high-volume electronics production.

Maintenance and Usage Guidelines

Although Sintered NdFeB Magnets are stable, proper handling ensures consistent performance:

-

Avoid mechanical shocks or dropping during assembly.

-

Do not expose to temperatures above the rated maximum for the magnet grade.

-

Keep away from strong external magnetic fields that may partially demagnetize the magnet.

-

Inspect mounting and housing for proper alignment and fixation.

-

Follow corrosion protection and coating guidelines to prevent environmental degradation.

Following these guidelines prolongs magnet performance and device reliability.

Frequently Asked Questions (FAQ)

Q1: Are Sintered NdFeB Magnets necessary for all consumer electronics?

A: They are ideal for compact, high-performance, or precision devices, but lower-end electronics may use ferrite or bonded magnets.

Q2: Can magnet shapes and sizes be customized?

A: Yes, Sintered NdFeB Magnets can be manufactured in various sizes, shapes, and grades according to device requirements.

Q3: What advantages do Sintered NdFeB Magnets have over bonded NdFeB or ferrite magnets?

A: They offer higher magnetic strength, better coercivity, improved thermal stability, and smaller size for high-performance applications.

Conclusion

Sintered NdFeB Magnets for Consumer Electronics provide compact, high-strength magnetic solutions essential for modern devices. With precise manufacturing, consistent performance, and long-term reliability, Ningbo Jinlun Magnet Technology Co., Ltd. supplies magnets that support the efficiency, miniaturization, and functionality of consumer electronics products worldwide.

EN

EN English

English 中文简体

中文简体 русский

русский Deutsch

Deutsch 日本語

日本語 한국어

한국어