Why Are Sintered NdFeB Magnets the Core of New Energy Vehicle Motors?

In the global wave of automotive electrification, the performance of new energy vehicle (NEV) motors directly determines driving experience, range, and energy efficiency. Behind the efficient operation of these "power cores" lies a critical material—sintered NdFeB magnets, known as the "king of permanent magnets." Their unique properties make them irreplaceable in NEV motor applications, becoming the invisible backbone of the green transportation revolution.

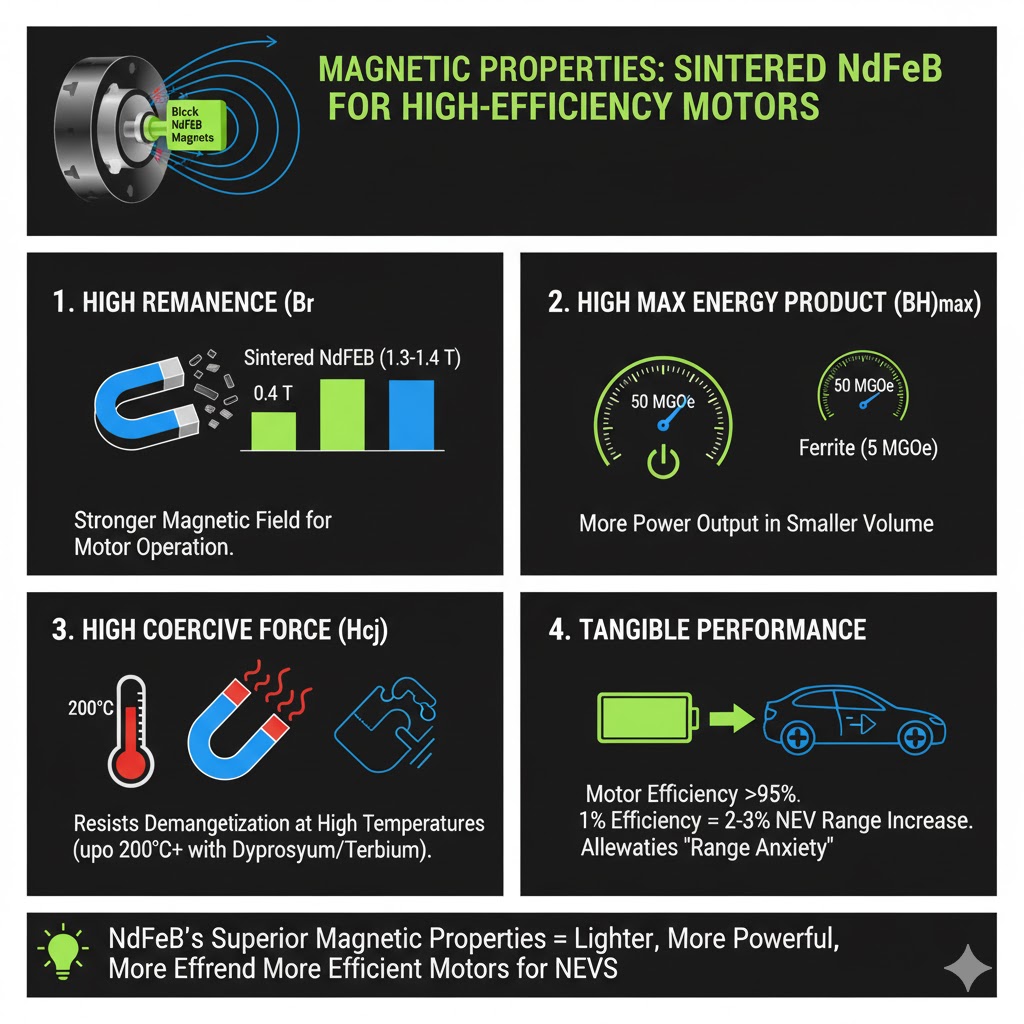

What Magnetic Properties Make Sintered NdFeB Magnets Irreplaceable for High-Efficiency Motors?

The core advantage of sintered NdFeB magnets stems from their exceptional magnetic properties, which form the basis for high-performance NEV motors. Composed primarily of neodymium (25%-35%), iron (65%-75%), and boron (about 1%), their unique tetragonal crystal structure endows them with magnetic capabilities that far surpass traditional materials.

Three key indicators define their superiority: high remanence (Br), high coercive force (Hcj), and high maximum energy product ((BH) max). Their remanence can reach 1.3-1.4 Tesla (T), far exceeding ferrite magnets (around 0.4T) , directly determining the magnetic field strength available for motor operation. The maximum energy product, a comprehensive measure of magnetic storage capacity, has breakthrough 50 MGOe (megagauss- oersted) in high-end products, more than 10 times that of ferrite magnets and significantly higher than samarium-cobalt alternatives . This means motors can output greater power without increasing volume.

Meanwhile, their coercive force can exceed 1990 kA/m for ultra-high coercivity grades, and with heavy rare earth doping (dysprosium, terbium), grades with coercive force over 2600 kA/m are available, enabling them to withstand temperatures up to 200°C or higher . This perfectly adapts to the high-temperature environment inside NEV motors and avoids demagnetization failures. These properties translate directly into tangible performance: permanent magnet synchronous motors (PMSMs) using sintered NdFeB boast efficiency exceeding 95%, with every 1% increase extending NEV range by approximately 2%-3% , effectively alleviating users' "range anxiety."

Click to visit our products:sintered NdFeB magnet

How Do Sintered NdFeB Magnets Enable Compact and Lightweight NEV Motor Design?

Space and weight constraints are core challenges in NEV manufacturing, and sintered NdFeB magnets provide an optimal solution with their excellent strength-to-weight ratio. Their high magnetic density allows engineers to design smaller, lighter motors—critical for maximizing battery installation space and passenger compartment comfort.

The high maximum energy product of sintered NdFeB is the key to miniaturization: under the same power output requirement, the volume of the magnet can be significantly reduced compared to other materials. This allows NEV drive motors to achieve power densities of more than 5 kW per kilogram, a level difficult for traditional magnet materials to reach . Practically, this means motors using sintered NdFeB can reduce volume by 30% and weight by 20% compared to conventional motors of similar power . A typical pure electric vehicle consumes about 2-5 kg of sintered NdFeB magnets for its drive motor alone —these compact components deliver the powerful torque needed for smooth acceleration while freeing up valuable space for other critical components.

What Technologies Help Sintered NdFeB Magnets Withstand Harsh Motor Environments?

NEV motors operate under extreme conditions: high temperatures from continuous operation, vibration during driving, and exposure to moisture or coolants. Sintered NdFeB magnets' robust environmental adaptability, enhanced by targeted technologies, ensures long-term stable motor performance.

Heat resistance is achieved through advanced processes like grain boundary diffusion. This technology deposits trace heavy rare earth elements on magnet grain boundaries, significantly improving coercivity while reducing heavy rare earth usage by enhancing utilization to 85% —striking a balance between performance and cost . Cutting-edge developments have even pushed the maximum operating temperature to over 280°C , breaking traditional limits. To combat corrosion, post-sintering surface treatments such as nickel, zinc, or aluminum plating, and epoxy coating are essential. Advanced processes like magnetron sputtering combined with electroless plating can promote corrosion resistance by over 120% while reducing environmental impact . Additionally, strict production controls, such as maintaining oxygen content below 800 ppm, further enhance the material's stability in harsh conditions .

How Does the NEV Boom Interact with Sintered NdFeB Magnet Innovation?

The rise of NEVs has driven explosive demand for sintered NdFeB magnets, while technological advancements in the magnets have accelerated automotive electrification—a symbiotic relationship shaping both industries. As NEV adoption grows, the demand for high-performance magnets continues to surge, with projections that China's NEV sector alone will drive sintered NdFeB consumption to 68,000 tons by 2030, doubling 2024 levels .

This demand has spurred continuous innovation. Researchers are developing multi-component alloy diffusion technologies to simultaneously improve coercivity and maximum energy product—overcoming the traditional trade-off between these two key metrics . Efforts to reduce heavy rare earth dependence, such as through new alloy formulations and diffusion techniques, address both cost and supply chain concerns . Beyond drive motors, these magnets find widespread use in NEV auxiliary systems like electric power steering (EPS) and air conditioning compressors , forming a comprehensive material support system.

As materials science experts note, sintered NdFeB magnets solve the three core contradictions of NEV motors—efficiency, size, and reliability. Without this material breakthrough, the current pace of electrification would be significantly slower. For consumers, every smooth acceleration and extra mile driven owes a debt to this "magnetic core" working silently beneath the hood.

Jinlun Magnet specialized in the research and development, production, and sales of high-performance rare-earth permanent magnet materials.

-

Sales00@jlmagnet.com

Sales00@jlmagnet.com

-

+86-574-6321 2222

+86-574-6321 2222

-

No. 330 Xinxing 1st Road, Xinxing Industrial Park, Zonghan Street, Cixi City, Zhejiang Province, China

No. 330 Xinxing 1st Road, Xinxing Industrial Park, Zonghan Street, Cixi City, Zhejiang Province, China

Mobile QR Code

Copyright © Ningbo Jinlun Magnet Technology Co., Ltd. All Rights Reserved.

China sintered NdFeB magnet manufacturer wholesale sintered NdFeB magnet factory

EN

EN English

English 中文简体

中文简体 русский

русский Deutsch

Deutsch 日本語

日本語 한국어

한국어