Known as the "Magnet King", Why Must Block Sintered NdFeB Undergo Surface Coating Treatment?

What inherent properties of Block Sintered NdFeB make coating necessary?

Block Sintered NdFeB, often called the "magnet king" for its exceptional magnetic performance, has a fatal flaw in its chemical composition that demands surface protection: high susceptibility to corrosion. This magnet is primarily composed of neodymium (Nd), iron (Fe), and boron (B)—with iron accounting for roughly 60-70% of its weight . Iron, as a reactive metal, easily reacts with oxygen, moisture, and even mild acidic/alkaline substances in the environment to form rust (iron oxide).

Worse, neodymium is even more chemically active than iron. When exposed to air, neodymium on the magnet’s surface quickly oxidizes to form a loose, porous oxide layer. This layer cannot act as a protective barrier; instead, it allows moisture and oxygen to seep into the interior, triggering "intergranular corrosion"—a process that erodes the bonds between the magnet’s internal grains . Over time, this corrosion not only fades the magnet’s surface but also causes it to crack, peel, or even crumble, directly destroying its structural integrity.

Unlike other magnets (such as ferrite magnets) with relatively stable surfaces, Block Sintered NdFeB’s sintering process further amplifies this vulnerability. Sintering creates tiny pores inside the magnet, which act as "channels" for corrosive substances to penetrate deeply. Without a sealed coating, these pores become hidden corrosion hotspots, accelerating the magnet’s degradation.

Click to visit our products:Block Sintered NdFeB

Click to visit our products:Block Sintered NdFeB

How does corrosion damage Block Sintered NdFeB’s magnetic performance?

Corrosion does not just affect Block Sintered NdFeB’s appearance and structure—it directly undermines the "core advantage" that earns it the "magnet king" title: its magnetic strength.

The magnet’s magnetic properties (such as remanence, coercivity, and maximum energy product) depend entirely on the orderly arrangement of its internal magnetic domains. When corrosion occurs, the formation of oxide layers (like neodymium oxide and iron oxide) disrupts this order. These non-magnetic oxide substances act as "barriers" between magnetic grains, weakening the magnetic coupling force inside the magnet . For example, a study found that after 30 days of exposure to a humid environment (relative humidity 95%, temperature 40°C), an uncoated Block Sintered NdFeB magnet lost 15-20% of its coercivity—a key indicator of its ability to resist demagnetization .

In severe cases, intergranular corrosion can split the magnet into small fragments. Each fragment has an independent magnetic field, and the mutual interference between these fields cancels out part of the overall magnetic force. For application scenarios that require stable magnetic performance (such as new energy vehicle motors or precision sensors), even a 5% drop in magnetic strength can lead to equipment malfunctions—like reduced motor efficiency or inaccurate sensor readings.

Additionally, corrosion products (such as rust powder) can contaminate the surrounding environment of the magnet. In electronic devices, these conductive rust particles may cause short circuits between components; in medical equipment, they could pose hygiene risks. Thus, coating is not just about protecting the magnet itself, but also about ensuring the safety and reliability of the entire system it belongs to.

What key functions does surface coating serve for Block Sintered NdFeB?

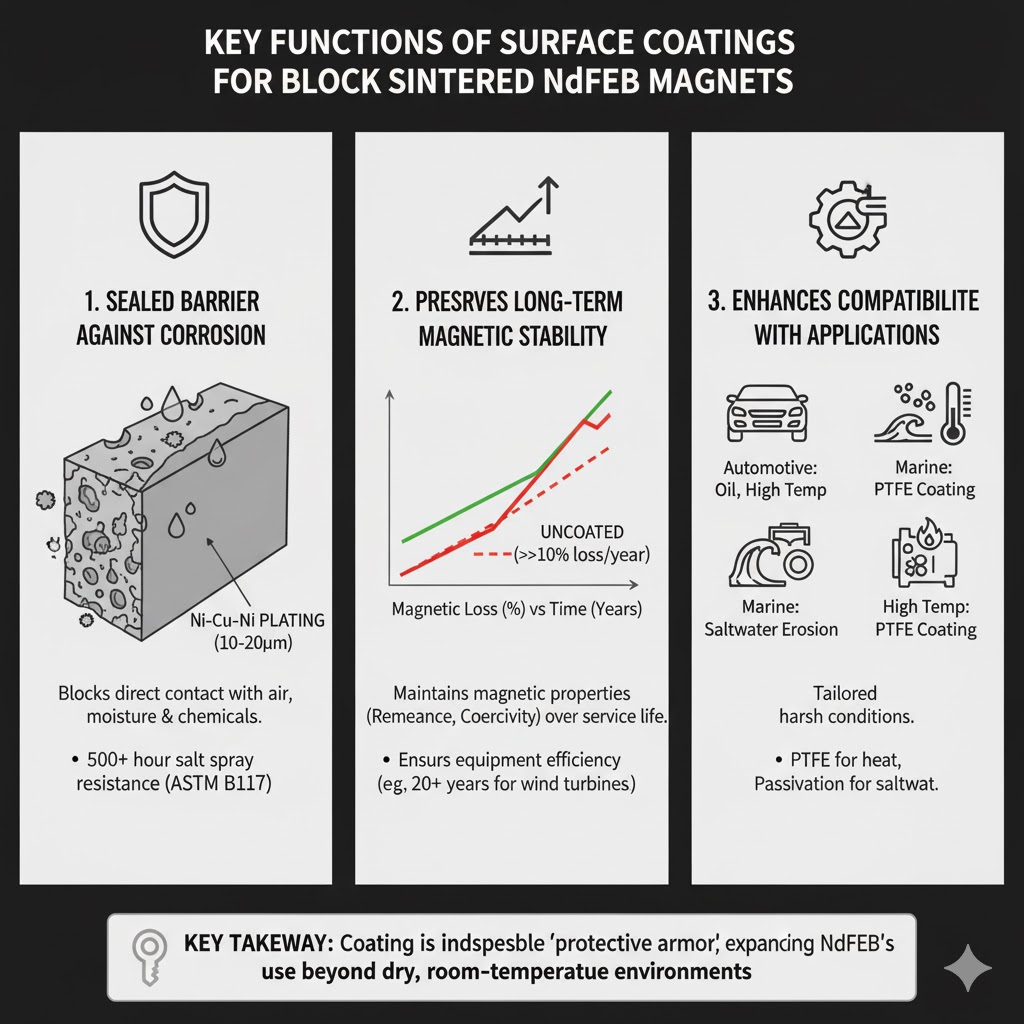

Surface coating acts as a "protective armor" tailored to Block Sintered NdFeB’s vulnerabilities, fulfilling three core functions that are indispensable for its practical use.

First, it provides a sealed barrier against corrosion. A high-quality coating (such as nickel-copper-nickel plating or epoxy resin coating) forms a dense, continuous film on the magnet’s surface—covering not only the outer layer but also filling the tiny pores left by sintering. This film blocks direct contact between the magnet’s active components (neodymium and iron) and air, moisture, or corrosive chemicals, fundamentally stopping the initiation of oxidation and corrosion . For example, a nickel-copper-nickel coating with a thickness of 10-20μm can resist 500+ hours of neutral salt spray testing (per ASTM B117 standards) without visible corrosion—far exceeding the 24-hour limit of uncoated magnets.

Second, coating preserves long-term magnetic stability. By preventing corrosion, the coating maintains the integrity of the magnet’s internal magnetic domain structure, ensuring its magnetic properties (remanence, coercivity, etc.) remain within the design range throughout its service life. In long-term applications (such as wind turbine generators, which require 20+ years of operation), a reliable coating can reduce the annual magnetic loss rate to less than 1%, ensuring the equipment’s long-term efficiency.

Third, coating enhances compatibility with application scenarios. Different use environments have unique demands: magnets in automotive undercarriages need to resist oil and high temperatures, while those in marine equipment must withstand saltwater erosion. Specialized coatings (like PTFE coating for high temperatures or passivation coatings for saltwater resistance) allow Block Sintered NdFeB to adapt to these harsh conditions. Without such customization, even the strongest "magnet king" would be limited to dry, room-temperature environments—greatly reducing its application scope.

Are there scenarios where Block Sintered NdFeB can skip coating?

Given the critical role of coating, is there any situation where Block Sintered NdFeB can be used without surface treatment? The answer is extremely limited—and even in these cases, strict conditions must be met.

The only feasible "no-coating" scenarios are short-term, ultra-controlled environments where the magnet is completely isolated from corrosion triggers. For example:

- In laboratory experiments that last only a few hours (such as temporary magnetic field testing), where the magnet is stored in a dry, inert gas (like argon) environment and never exposed to air or moisture.

- In disposable, low-demand products (such as certain temporary magnetic fasteners) that are used once and discarded within days, with no requirement for long-term performance or structural stability.

Even in these cases, risks remain. A small leak in the inert gas container or accidental exposure to ambient air during operation could still cause surface oxidation. For any application that requires the magnet to work for more than a week, or to be used in environments with humidity above 30% (close to normal indoor humidity), coating is non-negotiable.

Some may mistakenly believe that "high-coercivity Block Sintered NdFeB" is more corrosion-resistant and can skip coating. This is a misunderstanding: coercivity refers to the magnet’s ability to resist demagnetization, not its chemical stability. High-coercivity magnets still contain the same reactive neodymium and iron components, so they are just as susceptible to corrosion as regular Block Sintered NdFeB.

Conclusion: Why is coating a "must-have" for Block Sintered NdFeB’s value?

For Block Sintered NdFeB, surface coating is not an optional "upgrade" but a fundamental "requirement" to realize its value. Its inherent chemical reactivity and porous sintered structure make corrosion inevitable without protection—and corrosion directly destroys both its structural integrity and magnetic performance.

The "magnet king" title is earned through its superior magnetic strength, but this strength can only be maintained with the protection of a coating. Whether in new energy vehicles, consumer electronics, medical devices, or renewable energy systems, coating ensures that Block Sintered NdFeB can reliably perform its role for years. In essence, coating is the bridge that connects the magnet’s "potential" (exceptional magnetic properties) to its "practicality" (stable, long-term use in real-world environments)—without this bridge, the "magnet king" would remain a high-performance but unusable material.

News categories

Product categories

Exhibition Information

Content

- 1 What inherent properties of Block Sintered NdFeB make coating necessary?

- 2 How does corrosion damage Block Sintered NdFeB’s magnetic performance?

- 3 What key functions does surface coating serve for Block Sintered NdFeB?

- 4 Are there scenarios where Block Sintered NdFeB can skip coating?

- 5 Conclusion: Why is coating a "must-have" for Block Sintered NdFeB’s value?

Jinlun Magnet specialized in the research and development, production, and sales of high-performance rare-earth permanent magnet materials.

-

Sales00@jlmagnet.com

Sales00@jlmagnet.com

-

+86-574-6321 2222

+86-574-6321 2222

-

No. 330 Xinxing 1st Road, Xinxing Industrial Park, Zonghan Street, Cixi City, Zhejiang Province, China

No. 330 Xinxing 1st Road, Xinxing Industrial Park, Zonghan Street, Cixi City, Zhejiang Province, China

Mobile QR Code

Copyright © Ningbo Jinlun Magnet Technology Co., Ltd. All Rights Reserved.

China sintered NdFeB magnet manufacturer wholesale sintered NdFeB magnet factory

EN

EN English

English 中文简体

中文简体 русский

русский Deutsch

Deutsch 日本語

日本語 한국어

한국어