What Parameters Matter for Customized Sintered NdFeB Magnets? Temperature & Corrosion Guide

What temperature-related parameters are critical for customized sintered NdFeB magnets?

Temperature resistance is one of the most important parameters for customized sintered NdFeB magnets, as their magnetic properties are highly sensitive to heat. The first key parameter is Maximum Operating Temperature (Tₒₚ): this refers to the highest temperature at which the magnet can maintain its rated magnetic flux density without permanent loss. Sintered NdFeB magnets are classified by grade based on Tₒₚ: for example, N35 grade has a Tₒₚ of 80°C, while higher-grade magnets like N35SH have a Tₒₚ of 150°C, and UH-grade magnets can withstand up to 200°C. The second critical parameter is Curie Temperature (T꜀): this is the temperature at which the magnet loses all its magnetic properties (becoming paramagnetic). For most sintered NdFeB magnets, T꜀ ranges from 310°C to 380°C—while this is higher than typical operating temperatures, it is still a key consideration for applications exposed to short-term heat spikes (such as in automotive engines). The third parameter is Temperature Coefficient of Remanence (αBr): this measures the rate of magnetic flux loss per degree Celsius above room temperature (e.g., -0.12%/°C for SH-grade magnets). A lower (less negative) αBr indicates better magnetic stability at high temperatures.

Click to visit our products:customized sintered NdFeB magnets

Click to visit our products:customized sintered NdFeB magnets

What corrosion resistance parameters and treatments are essential for customized sintered NdFeB magnets?

Sintered NdFeB magnets are prone to corrosion (due to their high neodymium content, which reacts with oxygen and moisture), so corrosion resistance parameters and treatments are critical for customization. The first parameter is Corrosion Rate: this measures how quickly the magnet deteriorates in a specific environment (e.g., saltwater, humidity). Uncoated sintered NdFeB magnets have a high corrosion rate (up to 0.1 mm/year in humid environments), so protective coatings are mandatory for most applications. The second key consideration is coating type and thickness: common coatings include nickel-copper-nickel (Ni-Cu-Ni), zinc (Zn), epoxy (Ep), and aluminum (Al). Ni-Cu-Ni coatings (with a thickness of 10-20 μm) offer excellent corrosion resistance (passing 48-96 hours of salt spray testing per ASTM B117), making them suitable for outdoor or marine applications. Epoxy coatings (20-50 μm thick) provide superior chemical resistance (resisting acids and alkalis) but are less durable for mechanical wear. The third parameter is porosity: sintered NdFeB magnets have a porous structure (porosity of 2-5%), so coatings must penetrate these pores to prevent internal corrosion—some manufacturers use sealing treatments (such as impregnation with anti-corrosion agents) to enhance pore protection.

How to match temperature and corrosion parameters to specific application requirements?

Matching temperature and corrosion parameters to the application is essential to ensure the customized sintered NdFeB magnet performs reliably. For automotive applications (e.g., electric vehicle motor magnets), the magnet must withstand temperatures up to 150°C (requiring SH or UH grade) and resist corrosion from engine fluids (so a Ni-Cu-Ni coating is ideal). For consumer electronics (e.g., smartphone speakers), lower temperatures (up to 80°C, N35 grade) are sufficient, but the magnet must be thin and have a smooth coating (like epoxy) to fit in compact designs. For outdoor renewable energy applications (e.g., wind turbine generators), the magnet must handle temperatures up to 120°C (H or SH grade) and resist long-term exposure to humidity and salt (requiring a thick Ni-Cu-Ni coating plus a secondary sealant). For medical devices (e.g., MRI equipment), the magnet must have ultra-low magnetic flux loss at body temperature (37°C, so a low αBr of -0.08%/°C or better) and be biocompatible—epoxy coatings or passivation treatments (to avoid nickel leaching) are preferred here. For industrial sensors used in high-humidity factories, a combination of Zn coating (for cost-effectiveness) and a moisture-resistant sealant can balance corrosion protection and budget needs.

What other performance parameters should be considered for customized sintered NdFeB magnets?

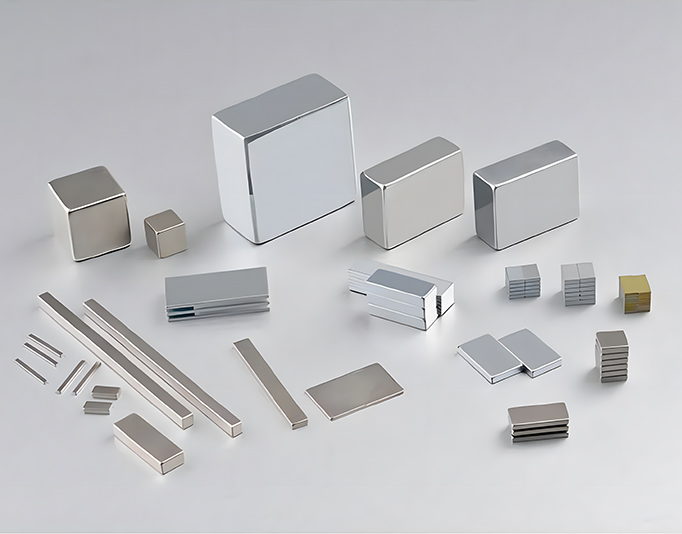

Beyond temperature and corrosion resistance, two other key parameters impact the suitability of customized sintered NdFeB magnets: magnetic strength and mechanical tolerance. Magnetic strength is measured by Remanence (Br) (the maximum magnetic flux density) and Coercivity (HcJ) (the resistance to demagnetization). For high-torque applications (e.g., industrial motors), a Br of 1.2-1.4 T and HcJ of 800-1200 kA/m are typically required; for low-power applications (e.g., refrigerator door seals), lower values (Br of 1.0-1.1 T, HcJ of 600-800 kA/m) suffice. Mechanical tolerance is equally important, especially for small or precision-fit magnets: for example, magnets used in microelectronics may require dimensional tolerances of ±0.01 mm, while larger industrial magnets can tolerate ±0.1 mm. Additionally, shape customization (e.g., discs, rings, blocks, or complex geometries) must align with the application’s space constraints—some shapes (like thin discs) may require reinforcement to prevent cracking during installation, which can be addressed by adjusting the magnet's grain structure during sintering.

Jinlun Magnet specialized in the research and development, production, and sales of high-performance rare-earth permanent magnet materials.

-

Sales00@jlmagnet.com

Sales00@jlmagnet.com

-

+86-574-6321 2222

+86-574-6321 2222

-

No. 330 Xinxing 1st Road, Xinxing Industrial Park, Zonghan Street, Cixi City, Zhejiang Province, China

No. 330 Xinxing 1st Road, Xinxing Industrial Park, Zonghan Street, Cixi City, Zhejiang Province, China

Mobile QR Code

Copyright © Ningbo Jinlun Magnet Technology Co., Ltd. All Rights Reserved.

China sintered NdFeB magnet manufacturer wholesale sintered NdFeB magnet factory

EN

EN English

English 中文简体

中文简体 русский

русский Deutsch

Deutsch 日本語

日本語 한국어

한국어