Sintered NdFeB Magnets: How to Balance Magnetic Performance and Stability? Impact of Application Scenarios

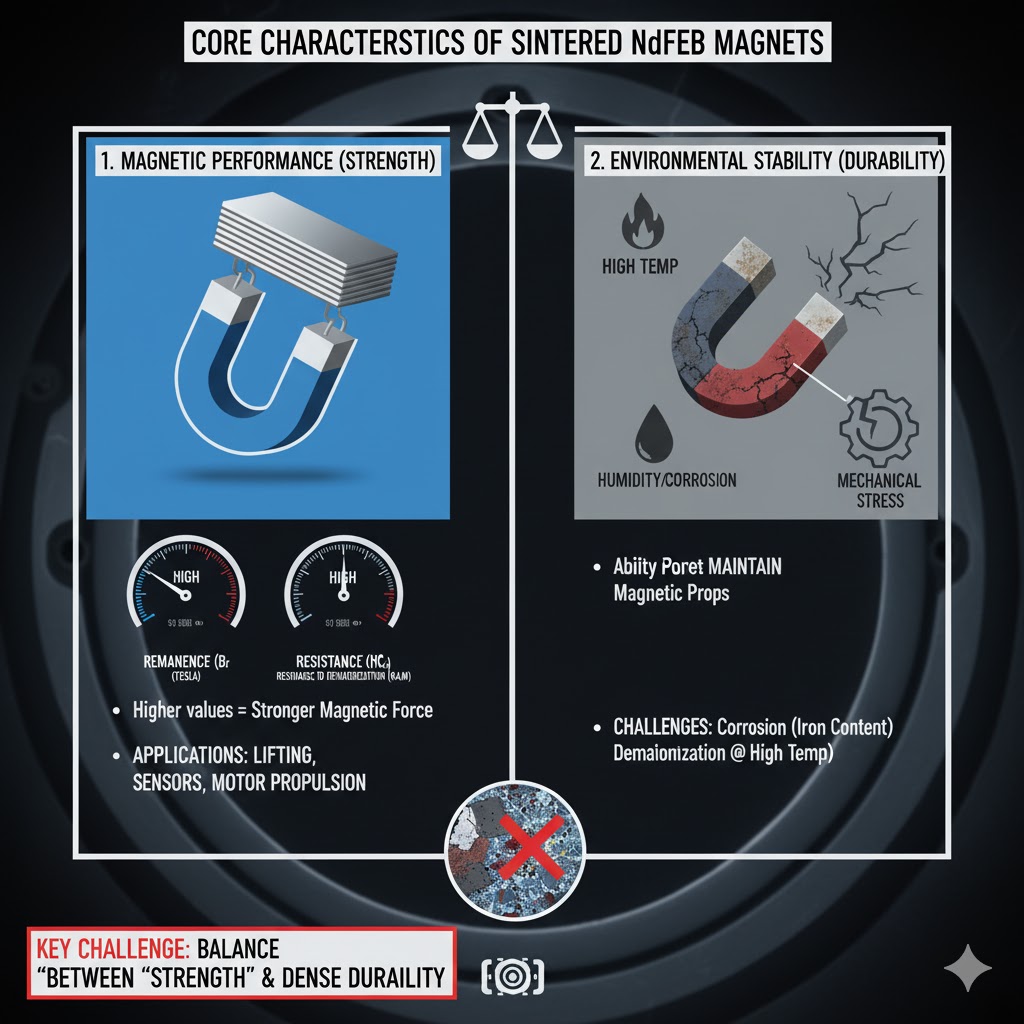

What Are the Core Traits of Sintered NdFeB Magnets?

Sintered NdFeB (Neodymium-Iron-Boron) Magnets are among the strongest permanent magnets available, widely used in industries like electronics, automotive, and renewable energy. Their "core traits" revolve around two conflicting yet critical properties: magnetic performance and environmental stability. Magnetic performance is defined by metrics like remanence (Br, the maximum magnetic flux density) and coercivity (HcJ, the resistance to demagnetization)—higher values mean stronger magnetic force for tasks like lifting, sensor activation, or motor propulsion. Stability, by contrast, refers to the magnet’s ability to retain these properties under harsh conditions: high/low temperatures, humidity, corrosion, or mechanical stress. Traditional sintered NdFeB magnets are naturally prone to corrosion (due to their iron content) and can lose magnetism at elevated temperatures, making the balance between "strength" and "durability" a key challenge for manufacturers and users alike.

How to Balance Magnetic Performance and Stability in Sintered NdFeB Magnets?

Balancing these two properties requires intentional material engineering, processing techniques, and protective treatments—each targeting specific trade-offs (e.g., boosting coercivity without reducing remanence). Below are four core strategies:

1. Alloy Composition Optimization

The base NdFeB alloy is modified by adding "dopant elements" to enhance stability without sacrificing magnetic strength. For example:

- Adding dysprosium (Dy) or terbium (Tb) increases coercivity, making the magnet more resistant to demagnetization at high temperatures (critical for automotive or industrial motor use). However, excessive Dy/Tb can slightly reduce remanence—so engineers carefully control their concentration (typically 1–5% by weight) to strike a balance.

- Adding cobalt (Co) improves both temperature stability and mechanical strength, while neodymium (Nd) content is adjusted to maintain high remanence. For low-temperature applications (e.g., medical devices in cold storage), small amounts of gallium (Ga) are added to prevent brittleness without weakening magnetic force.

This "precision alloying" ensures the magnet meets performance targets (e.g., Br ≥ 1.4 T) while withstanding the intended environmental stress (e.g., operating temperatures up to 150°C).

2. Sintering Process Control

The sintering process (heating compacted NdFeB powder to high temperatures) directly impacts both magnetic performance and structural stability. Key parameters include:

- Sintering temperature: Higher temperatures (1,050–1,100°C) promote denser grain structures, which boost remanence by reducing air gaps in the magnet. However, over-sintering can cause grain growth, which weakens coercivity. Engineers use precise temperature ramps (e.g., 5°C per minute) and holding times (2–4 hours) to achieve optimal density (≥ 7.5 g/cm³) without compromising stability.

- Cooling rate: Rapid cooling (quenching) preserves fine grain structures, which enhance coercivity, but can introduce internal stresses that reduce mechanical stability. Controlled cooling (10–20°C per minute) balances grain size and stress, ensuring the magnet is both strong magnetically and resistant to cracking.

3. Protective Coatings for Corrosion Resistance

Sintered NdFeB’s iron content makes it vulnerable to rust in humid or corrosive environments (e.g., marine electronics or outdoor sensors)—rust not only degrades structural stability but also disrupts magnetic flux. Protective coatings resolve this without affecting magnetic performance:

- Nickel-copper-nickel (Ni-Cu-Ni) plating: A common choice for general use, it forms a dense, scratch-resistant barrier against moisture. The thin coating (10–20 μm) has minimal impact on magnetic flux (less than 2% reduction in Br).

- Epoxy or PTFE coating: Used for high-corrosion environments (e.g., chemical processing equipment), these organic coatings are thicker (10–20 μm) but lightweight. They are paired with a pre-treatment (e.g., zinc phosphate) to improve adhesion, ensuring long-term stability without blocking magnetic force.

- Aluminum coating: Ideal for high-temperature applications (up to 200°C), aluminum forms a self-healing oxide layer that prevents corrosion, even if scratched. It is often used in automotive underhood components where both heat and moisture are present.

4. Post-Sintering Heat Treatment

Post-sintering annealing (heating the magnet to lower temperatures after sintering) refines the magnetic domain structure, optimizing both performance and stability:

- Aging treatment: Heating to 450–500°C for 1–2 hours precipitates fine secondary phases (e.g., Nd-rich regions) that pin magnetic domains, increasing coercivity without reducing remanence. This is critical for magnets used in high-stress applications (e.g., wind turbine generators).

- Stress relief annealing: Lower-temperature heating (200–300°C) reduces internal stresses from sintering, improving mechanical stability (e.g., resistance to vibration in electric vehicle motors) without altering magnetic properties.

Does the Application Scenario Directly Influence Sintered NdFeB Magnet Selection?

Yes—application scenarios dictate which property (magnetic performance or stability) takes priority, as well as specific requirements for size, shape, and coating. Below are three common scenarios and how they guide selection:

1. High-Temperature Scenarios (e.g., Automotive Motors, Industrial Heaters)

In applications where operating temperatures exceed 120°C (e.g., electric vehicle traction motors or engine-mounted sensors), stability (temperature resistance) is prioritized over maximum remanence. Key selection criteria include:

- High coercivity grades: Magnets with HcJ ≥ 1500 kA/m (e.g., N48SH or N52UH grades) to resist demagnetization at 150–200°C.

- Alloy with Dy/Tb addition: Ensures temperature stability, even if remanence is slightly lower (e.g., Br = 1.35 T vs. 1.45 T for standard grades).

- Heat-resistant coatings: Aluminum or high-temperature epoxy coatings to prevent oxidation at elevated temperatures.

For example, a motor in a hybrid vehicle requires a magnet that maintains 90% of its coercivity at 180°C—so a Dy-doped, Ni-Cu-Ni plated N50UH grade is chosen over a higher-remanence but less stable N55 grade.

2. High-Magnetic-Force Scenarios (e.g., Magnetic Separators, Loudspeakers)

In applications where maximum magnetic strength is critical (e.g., separating iron filings from industrial waste or powering high-fidelity loudspeakers), magnetic performance (remanence) is prioritized, with stability tailored to the environment:

- High remanence grades: Magnets with Br ≥ 1.4 T (e.g., N52 or N55 grades) to generate strong magnetic fields.

- Minimal Dy/Tb addition: Reduces coercivity slightly but preserves remanence—acceptable if the application operates at room temperature (20–40°C).

- Basic corrosion protection: Ni-Cu-Ni plating for indoor use (e.g., loudspeakers) or epoxy coating for mild humidity (e.g., indoor separators).

A magnetic separator in a recycling plant, for instance, uses N55 grade magnets to maximize iron capture, with a thin Ni-Cu-Ni coating to resist dust and occasional moisture—temperature stability is less critical here, as the plant operates at 25°C.

3. Corrosive/Humid Scenarios (e.g., Marine Sensors, Medical Devices)

In environments with high moisture, salt, or chemicals (e.g., underwater navigation sensors or medical equipment in sterile rooms), corrosion stability is non-negotiable, with magnetic performance adjusted to match:

- High-corrosion coatings: Thick epoxy (10–20 μm) or PTFE coatings, often with a zinc undercoat for marine use.

- Alloy resistance: Cobalt-added alloys to improve mechanical stability in humid conditions, preventing cracking from moisture absorption.

- Moderate magnetic grades: Balanced Br (1.3–1.4 T) and HcJ (1200–1400 kA/m) to ensure performance isn’t compromised by coating thickness.

A marine depth sensor, for example, uses an epoxy-coated N45SH grade magnet— the coating protects against saltwater corrosion, while the SH grade ensures stability in water temperatures ranging from 0–60°C.

Click to visit our products:sintered NdFeB magnets

Click to visit our products:sintered NdFeB magnets

What Mistakes Are Common When Balancing Performance and Stability?

Even with clear strategies, two common mistakes can undermine the balance of sintered NdFeB magnets:

1. Over-Optimizing One Property at the Expense of the Other

Some users prioritize maximum remanence (e.g., choosing N55 grade) for high-temperature applications, only to find the magnet demagnetizes quickly. Conversely, over-adding Dy to boost coercivity can make the magnet too brittle for vibration-prone uses (e.g., power tools). The solution is to define "critical limits" first: e.g., "must withstand 120°C and 500 hours of humidity" before selecting a grade.

2. Ignoring Coating-Magnetic Interaction

Thick coatings (e.g., >20 μm epoxy) can block magnetic flux, reducing effective remanence by 5–10%. Users sometimes select heavy coatings for corrosion protection without adjusting the magnet grade—for example, using an N42 grade with a thick coating when an N45 grade with a thinner coating would deliver better net performance. Engineers calculate "effective magnetic flux" (accounting for coating thickness) to avoid this.

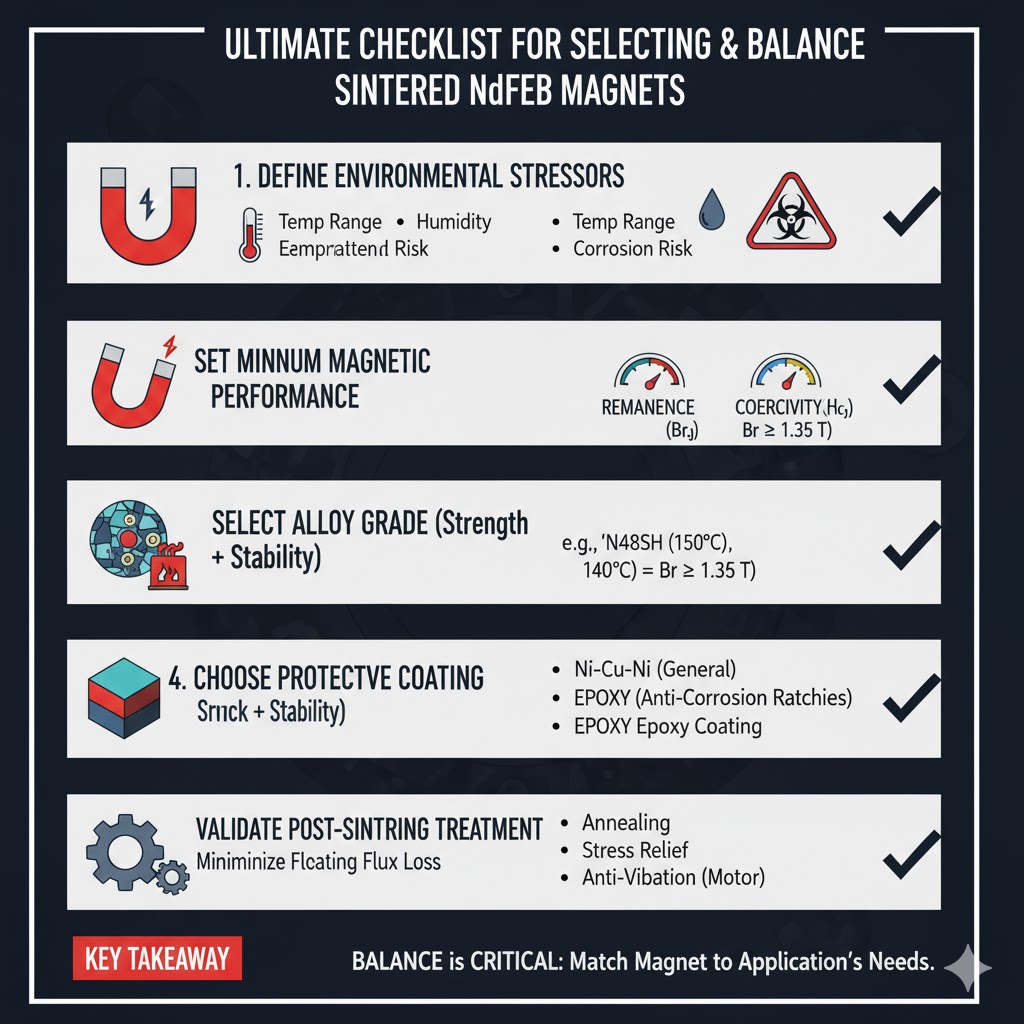

What's the Final Checklist for Balancing and Selecting Sintered NdFeB Magnets?

To ensure the magnet balances performance and stability for the intended use, follow this five-step checklist:

- Define the application’s critical environmental stress (temperature range, humidity, corrosion risk).

- Set minimum targets for magnetic performance (remanence, coercivity) based on functional needs (e.g., "must lift 50 kg" = Br ≥ 1.35 T).

- Select an alloy grade that meets both stability and performance targets (e.g., N48SH for 150°C use with Br ≥ 1.4 T).

- Choose a protective coating compatible with the environment and with minimal flux loss (e.g., Ni-Cu-Ni for general use, epoxy for corrosion).

- Verify post-sintering treatments (annealing, stress relief) align with mechanical needs (e.g., vibration resistance for motors).

By grounding selection in the application’s unique demands, users avoid over-engineering or underperforming magnets—ensuring sintered NdFeB delivers both the strength and durability required.

News categories

Product categories

Exhibition Information

Content

- 1 What Are the Core Traits of Sintered NdFeB Magnets?

- 2 How to Balance Magnetic Performance and Stability in Sintered NdFeB Magnets?

- 3 Does the Application Scenario Directly Influence Sintered NdFeB Magnet Selection?

- 4 What Mistakes Are Common When Balancing Performance and Stability?

- 5 What's the Final Checklist for Balancing and Selecting Sintered NdFeB Magnets?

Jinlun Magnet specialized in the research and development, production, and sales of high-performance rare-earth permanent magnet materials.

-

Sales00@jlmagnet.com

Sales00@jlmagnet.com

-

+86-574-6321 2222

+86-574-6321 2222

-

No. 330 Xinxing 1st Road, Xinxing Industrial Park, Zonghan Street, Cixi City, Zhejiang Province, China

No. 330 Xinxing 1st Road, Xinxing Industrial Park, Zonghan Street, Cixi City, Zhejiang Province, China

Mobile QR Code

Copyright © Ningbo Jinlun Magnet Technology Co., Ltd. All Rights Reserved.

China sintered NdFeB magnet manufacturer wholesale sintered NdFeB magnet factory

EN

EN English

English 中文简体

中文简体 русский

русский Deutsch

Deutsch 日本語

日本語 한국어

한국어