How to Protect Sintered NdFeB Magnets for Synchronous Motors from Corrosion?

Why Are Sintered NdFeB Magnets in Synchronous Motors Prone to Corrosion?

Before exploring protection methods, it's critical to understand the root causes of corrosion in sintered NdFeB (neodymium-iron-boron) magnets— the strongest permanent magnets available, but inherently vulnerable to degradation. This vulnerability is amplified in synchronous motors (used in EVs, industrial drives, and renewable energy systems), which often operate in harsh environments:

Material Composition Weakness:

Sintered NdFeB magnets contain 25–35% neodymium (Nd) and 60–70% iron (Fe)—both highly reactive metals. Nd oxidizes rapidly in air to form loose, porous oxides (Nd₂O₃), while Fe rusts (Fe₂O₃/Fe₃O₄) in the presence of moisture. The magnet’s sintered structure (formed by pressing and heating powder) also creates tiny pores (0.1–1 μm) across its surface—these pores trap moisture, oxygen, and contaminants (e.g., motor oil, dust), accelerating localized corrosion (pitting).

Synchronous Motor Operating Environments:

Synchronous motors expose magnets to corrosion triggers that worsen degradation:

Moisture: Motors in EVs (underbody), industrial pumps (near water), or wind turbines (outdoor) absorb humidity or water vapor, which reacts with Nd and Fe.

Temperature Fluctuations: Motors heat up during operation (80–150°C) and cool down when off—this "thermal cycling" causes condensation inside the motor, depositing liquid water on magnet surfaces.

Chemical Contaminants: Motor lubricants (with sulfur or chlorine additives), coolants (glycol-based), or industrial fumes (in factories) act as electrolytes, speeding up electrochemical corrosion (the primary cause of magnet failure).

Mechanical Stress: Rotor vibration in high-speed synchronous motors (e.g., EV traction motors) can crack protective coatings, exposing bare magnet material to corrosive elements.

Left unprotected, corrosion reduces the magnet’s magnetic flux density (by 5–20% within 1–2 years) and weakens its mechanical strength—eventually leading to rotor imbalance, motor efficiency drops, or complete magnet disintegration.

Click to visit our products:sintered NdFeB magnets in synchronous motors

Click to visit our products:sintered NdFeB magnets in synchronous motors

What Surface Coating Technologies Are Most Effective for Corrosion Protection?

Surface coatings are the first line of defense for sintered NdFeB magnets in synchronous motors—they act as a barrier between the magnet and corrosive elements. The choice of coating depends on the motor’s operating temperature, moisture exposure, and cost constraints. Below are the most effective options:

Electroless Nickel-Phosphorus (Ni-P) Coating (Most Common for Motors)

How It Works: A chemical deposition process that forms a uniform, dense nickel-phosphorus layer (5–20 μm thick) on the magnet surface. The coating is amorphous (non-crystalline) when deposited, and heat treatment (200–400°C) converts it to a hard, wear-resistant structure (HV 800–1000).

Corrosion Resistance: Ni-P coatings withstand 500–1000 hours of neutral salt spray (NSS) testing (per ASTM B117) without red rust—far exceeding the 240-hour minimum for motor applications. The coating seals surface pores and prevents electrolyte penetration.

Synchronous Motor Advantages:

Tolerates high temperatures (up to 200°C)—compatible with most synchronous motor operating ranges (80–150°C).

Excellent adhesion to sintered NdFeB (even on irregular magnet shapes, like arc segments for rotors).

Resists motor oil and coolants—no chemical reaction with common lubricants.

Limitations: Susceptible to cracking under extreme thermal cycling (e.g., EV motors that heat from 25°C to 150°C rapidly). For such cases, a "Ni-P + topcoat" (e.g., epoxy) is used to enhance flexibility.

Epoxy Resin Coating (Cost-Effective for Low-Moisture Environments)

How It Works: A liquid epoxy (thermosetting polymer) is sprayed or dipped onto the magnet, then cured at 80–120°C to form a thin (10–30 μm) film. Additives like ceramic particles or corrosion inhibitors (e.g., zinc phosphate) can be mixed in to boost performance.

Corrosion Resistance: Standard epoxy coatings withstand 200–400 hours of NSS testing; "high-performance" epoxy (with corrosion inhibitors) reaches 600 hours. The coating is impermeable to moisture and oils.

Synchronous Motor Advantages:

Low cost (1/3 the price of Ni-P)—ideal for budget-sensitive industrial motors (e.g., small pumps).

Flexible—resists cracking from vibration or thermal cycling (critical for EV traction motors).

Insulating properties—prevents electrical shorting between magnets and rotor components.

Limitations: Low temperature resistance (max 120°C)—not suitable for high-power synchronous motors (e.g., wind turbine generators that reach 150°C).

Physical Vapor Deposition (PVD) Coatings (High-Temperature, High-Performance)

How It Works: A vacuum-based process that evaporates metals (e.g., aluminum, chromium) or ceramics (e.g., Al₂O₃, TiN) and deposits them as a thin (1–5 μm) film on the magnet surface. PVD coatings are dense, uniform, and bond strongly to the magnet.

Corrosion Resistance: PVD Al₂O₃ coatings withstand 1000+ hours of NSS testing and resist oxidation up to 500°C. They are impervious to acids, alkalis, and motor coolants.

Synchronous Motor Advantages:

Extreme temperature tolerance—ideal for high-power synchronous motors (e.g., aircraft propulsion motors, industrial drives) that operate at 150–250°C.

Thin coating (no impact on magnet dimensions)—critical for precision rotor assemblies where magnet size affects balance.

Limitations: High cost (5x more than Ni-P) and limited to small-batch production—mostly used in aerospace or premium EV motors.

Zinc-Nickel (Zn-Ni) Alloy Coating (Saltwater-Resistant)

How It Works: An electroplating process that forms a 5–15 μm thick zinc-nickel alloy (10–15% nickel) on the magnet surface. The alloy forms a passive oxide layer (ZnO·NiO) that self-heals minor scratches.

Corrosion Resistance: Withstands 1000+ hours of NSS testing—excellent for motors exposed to saltwater (e.g., marine synchronous motors, coastal wind turbines).

Synchronous Motor Advantages:

Superior saltwater resistance—outperforms Ni-P in coastal or marine environments.

Good ductility—resists cracking from rotor vibration.

Limitations: Lower temperature resistance (max 150°C) and higher cost than Ni-P for non-marine applications.

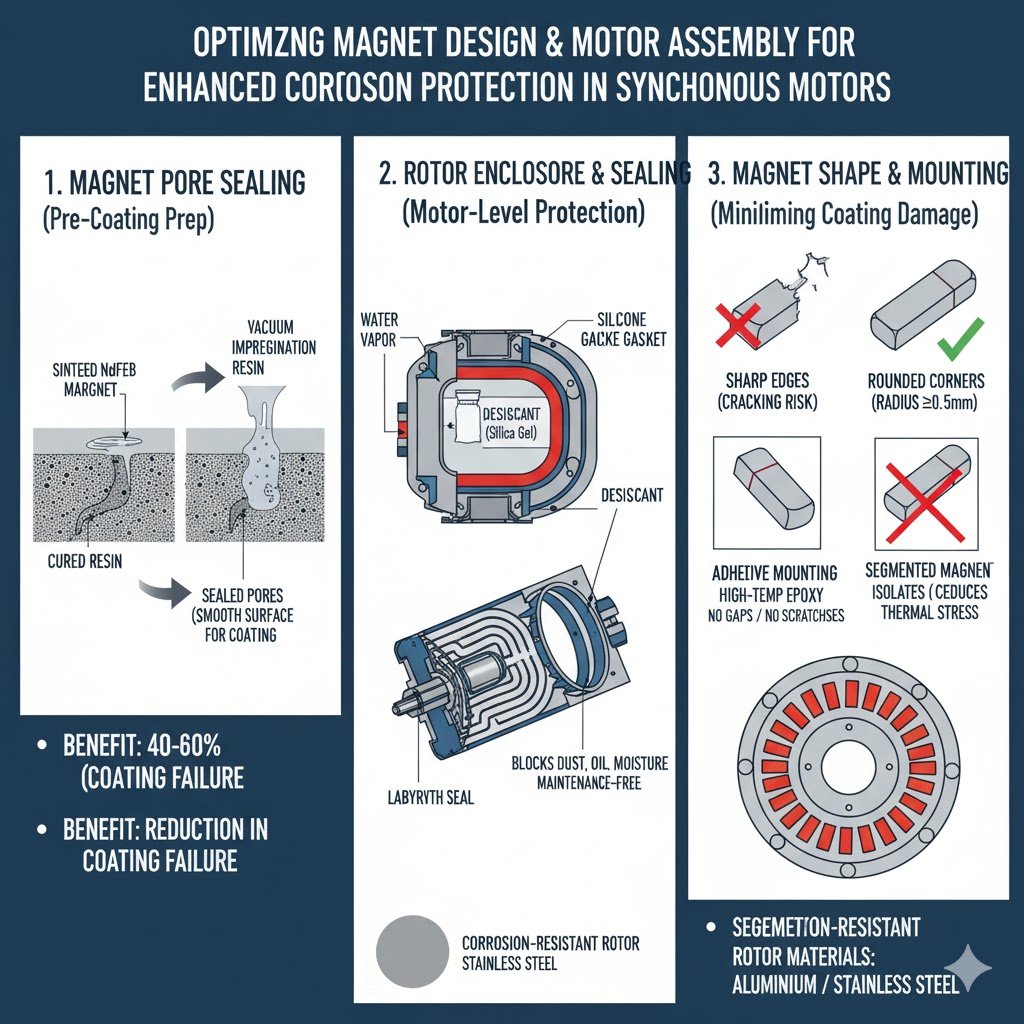

How to Optimize Magnet Design and Motor Assembly for Corrosion Protection?

Surface coatings alone are not enough—design choices for the magnet and motor assembly play a critical role in minimizing corrosion risk. These optimizations complement coatings and extend magnet lifespan:

Magnet Pore Sealing (Pre-Coating Preparation)

Sintered NdFeB’s surface pores trap moisture and contaminants, undermining coating effectiveness. Pre-coating pore sealing is essential:

Process: After sintering, magnets are dipped in a low-viscosity resin (e.g., acrylic or silicone) that penetrates pores (via vacuum impregnation), then cured to seal them. This creates a smooth, pore-free surface for coating adhesion.

Benefit: Sealed pores reduce coating failure by 40–60%—coatings no longer "bridge" over pores (which can crack and let moisture in). For synchronous motor magnets, this step is mandatory for Ni-P or PVD coatings.

Rotor Enclosure and Sealing (Motor-Level Protection)

The motor’s rotor (where magnets are mounted) should be enclosed to prevent moisture and contaminants from reaching magnets:

Hermetic Sealing: For motors in wet environments (e.g., EVs, marine applications), use a hermetically sealed rotor housing with rubber gaskets (e.g., nitrile or silicone) to block water vapor. Add a desiccant (e.g., silica gel) inside the housing to absorb residual moisture.

Labyrinth Seals: For high-speed synchronous motors (e.g., wind turbines), use labyrinth seals (interlocking metal fins) on the rotor shaft—these create a tortuous path that prevents dust, oil, and moisture from entering the magnet area. Labyrinth seals are maintenance-free and compatible with high temperatures.

Corrosion-Resistant Rotor Materials: Use aluminum or stainless steel (304/316) for the rotor core—these materials do not rust and prevent galvanic corrosion (when dissimilar metals, like iron and copper, react in the presence of electrolytes).

Magnet Shape and Mounting (Minimizing Coating Damage)

The way magnets are shaped and mounted in the rotor affects coating integrity:

Smooth Edges and Corners: Avoid sharp edges (which are prone to coating cracking) by designing magnets with rounded corners (radius ≥0.5 mm). Sharp edges can chip during assembly, exposing bare magnet material.

Adhesive Mounting (Instead of Mechanical Clamping): Use high-temperature epoxy adhesives (e.g., epoxy resins with ceramic fillers) to bond magnets to the rotor—mechanical clamps (e.g., metal brackets) can scratch coatings or create gaps where moisture accumulates. Adhesives also fill small gaps between magnets and the rotor, reducing moisture trapping.

Segmented Magnet Design: For large rotors, use small, segmented magnets (instead of one large magnet)—if one segment’s coating is damaged, corrosion is limited to that segment (preventing full rotor failure). Segments also reduce thermal stress (less expansion/contraction), lowering coating cracking risk.

What Maintenance and Operational Practices Prevent Corrosion?

Even with coatings and design optimizations, regular maintenance and proper operation are key to prolonging magnet life in synchronous motors. These practices address wear, coating damage, and environmental exposure:

Routine Inspection and Coating Repair

Visual Inspections: Every 6–12 months (or after exposure to extreme conditions, like heavy rain), inspect the motor’s interior (via inspection ports) for signs of corrosion: red/brown rust on magnets, bubbling or peeling coatings, or white oxide deposits.

Non-Destructive Testing (NDT): For critical motors (e.g., wind turbines), use ultrasonic testing to detect hidden corrosion under coatings (e.g., pitting inside pores) or eddy current testing to check coating thickness.

Spot Repairs: If small coating damage is found (e.g., a scratch), clean the area with alcohol, apply a small amount of epoxy resin (for low-temperature motors) or Ni-P touch-up paint (for high-temperature motors), and cure it per manufacturer guidelines. This prevents localized corrosion from spreading.

Moisture and Temperature Control

Dehumidification: For motors stored or operated in high-humidity environments (RH >60%), install a dehumidifier in the motor room or use a heatedrotor (a small heater inside the rotor) to keep the interior dry (RH <40%).

Avoid Thermal Shock: Minimize rapid temperature changes (e.g., starting a cold motor at full load)—thermal shock causes coating cracking. Instead, ramp up motor speed gradually (over 5–10 minutes) to allow the magnet and coating to heat evenly.

Coolant Maintenance: For liquid-cooled synchronous motors, check coolant levels and quality every 3–6 months. Replace coolant that is contaminated with water (use a refractometer to measure glycol concentration) or has a pH outside the 7–9 range (acidic/alkaline coolant corrodes coatings).

Contaminant Management

Oil and Dust Control: Keep the motor area clean—wipe up oil spills immediately (motor oil contains sulfur that degrades Ni-P coatings) and use air filters to prevent dust accumulation (dust traps moisture, accelerating corrosion).

Avoid Chemical Exposure: For industrial motors, ensure the motor is not exposed to acids, alkalis, or solvents (e.g., cleaning chemicals). If exposure occurs, rinse the motor’s exterior with water (if safe) and dry it thoroughly.

End-of-Life Handling

When a motor is retired, remove and inspect the magnets—if coatings are intact and corrosion is minimal, magnets can be reused in lower-power motors (e.g., small pumps). This reduces waste and lowers replacement costs. For corroded magnets, dispose of them properly (per local regulations) to avoid environmental contamination (Nd is a rare earth metal that can leach into soil/water).

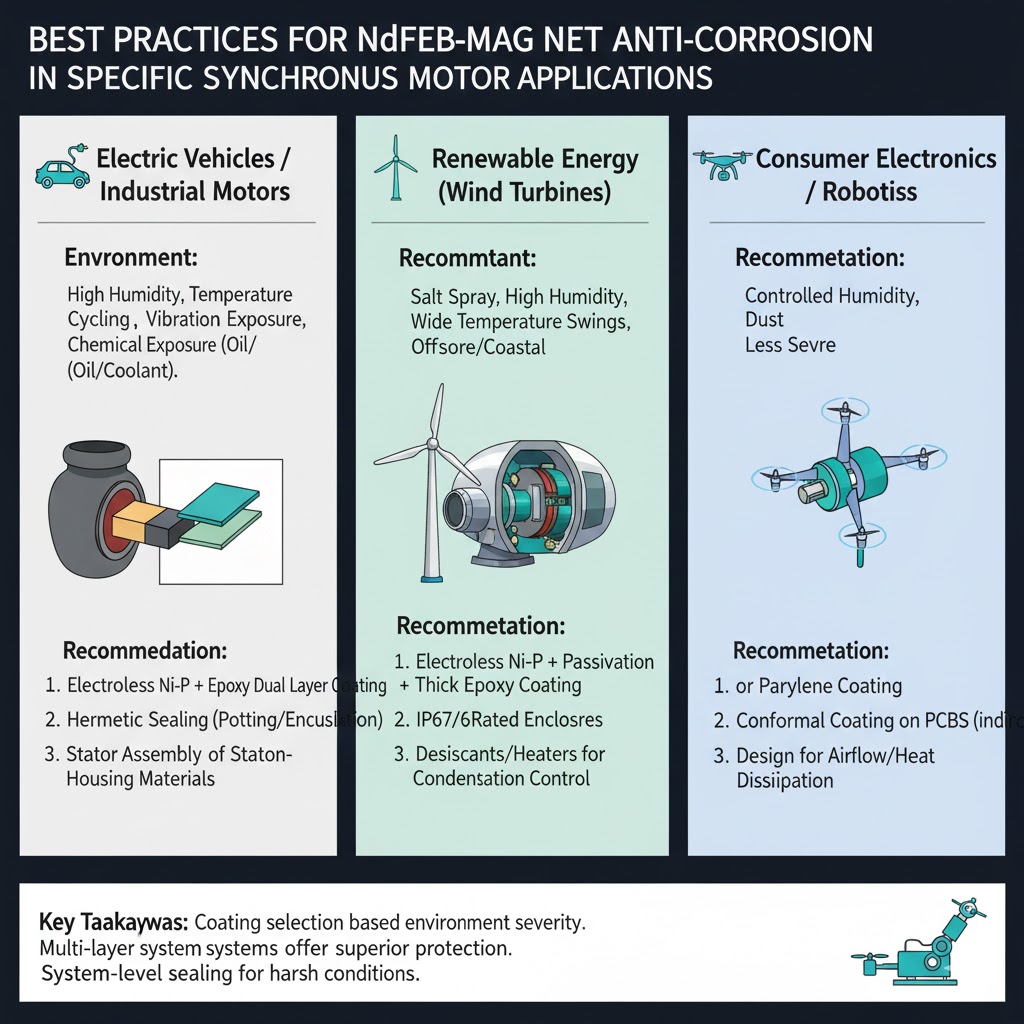

What Are the Best Practices for Specific Synchronous Motor Applications?

Corrosion protection needs vary by application—below are tailored recommendations for the most common synchronous motor uses:

EV Traction Motors (High Vibration, Thermal Cycling)

Coating: Ni-P + epoxy topcoat (Ni-P for corrosion resistance, epoxy for flexibility to withstand vibration/thermal cycling).

Design: Hermetically sealed rotor with silicone gaskets, segmented magnets bonded with high-temperature epoxy, and a desiccant in the rotor housing.

Maintenance: Inspect coolant quality every 6 months, avoid driving through deep water (to prevent housing leaks), and spot-repair coating damage after collisions.

Wind Turbine Generators (Outdoor, Saltwater Exposure)

Coating: Zn-Ni alloy (for coastal turbines) or PVD Al₂O₃ (for high-temperature inland turbines).

Design: Labyrinth seals on the rotor shaft, stainless steel rotor core, and a rain shield over the motor to prevent direct water exposure.

Maintenance: Annual NDT inspections, clean the motor exterior with fresh water every 3 months (to remove salt deposits), and replace desiccants every 2 years.

Industrial Pump Motors (Wet, Chemical Exposure)

Coating: Epoxy resin with corrosion inhibitors (cost-effective) or Ni-P (for chemical resistance).

Design: Hermetic rotor sealing, adhesive-mounted magnets, and a corrosion-resistant rotor housing (aluminum).

Maintenance: Check for coolant leaks monthly, replace worn gaskets every 12 months, and avoid using harsh cleaning chemicals near the motor.

In summary, protecting sintered NdFeB magnets in synchronous motors requires a multi-layered approach: effective surface coatings (matched to the application), design optimizations (pore sealing, rotor sealing), and regular maintenance (inspection, moisture control). By combining these strategies, manufacturers and operators can extend magnet life from 5–8 years to 15–20 years, reducing motor downtime and replacement costs—critical for the reliability of EVs, renewable energy systems, and industrial equipment.

News categories

Product categories

Exhibition Information

Content

- 1 Why Are Sintered NdFeB Magnets in Synchronous Motors Prone to Corrosion?

- 2 What Surface Coating Technologies Are Most Effective for Corrosion Protection?

- 3 How to Optimize Magnet Design and Motor Assembly for Corrosion Protection?

- 4 What Maintenance and Operational Practices Prevent Corrosion?

- 5 What Are the Best Practices for Specific Synchronous Motor Applications?

Jinlun Magnet specialized in the research and development, production, and sales of high-performance rare-earth permanent magnet materials.

-

Sales00@jlmagnet.com

Sales00@jlmagnet.com

-

+86-574-6321 2222

+86-574-6321 2222

-

No. 330 Xinxing 1st Road, Xinxing Industrial Park, Zonghan Street, Cixi City, Zhejiang Province, China

No. 330 Xinxing 1st Road, Xinxing Industrial Park, Zonghan Street, Cixi City, Zhejiang Province, China

Mobile QR Code

Copyright © Ningbo Jinlun Magnet Technology Co., Ltd. All Rights Reserved.

China sintered NdFeB magnet manufacturer wholesale sintered NdFeB magnet factory

EN

EN English

English 中文简体

中文简体 русский

русский Deutsch

Deutsch 日本語

日本語 한국어

한국어