Ring Sintered NdFeB magnets are a core product form within the sintered neodymium-iron-boron permanent magnet family, widely used in modern electromechanical systems. This category includes ring-shaped magnets manufactured through powder metallurgy sintering processes, offering high magnetic energy density, stable magnetic performance, and precise dimensional control. Ring Sintered NdFeB magnets are commonly applied in synchronous motors, servo motors, generators, sensors, and other rotating or axial magnetic field systems where uniform magnetic distribution is required.

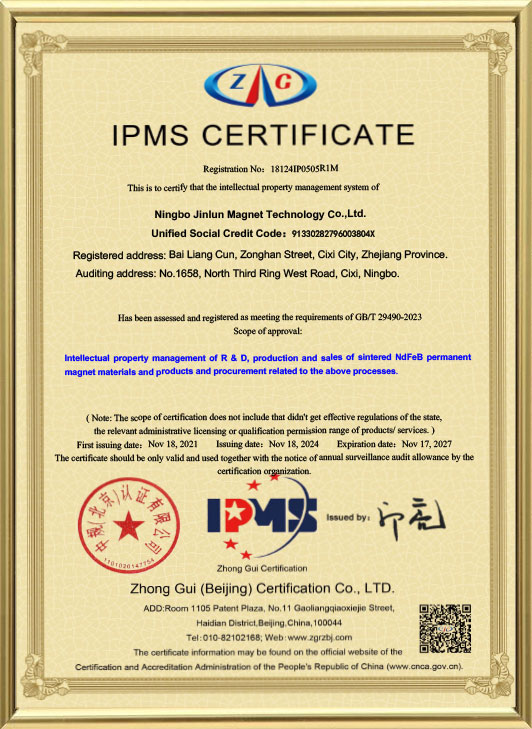

As a structural type, Ring Sintered NdFeB combines the intrinsic advantages of sintered NdFeB material with a geometry optimized for rotational symmetry, making it suitable for both radial and axial magnetization designs. Ningbo Jinlun Magnet Technology Co., Ltd. supplies Ring Sintered NdFeB magnets with controlled magnetic properties and consistent quality for industrial and motor-driven applications.

Working Principle of Ring Sintered NdFeB in Equipment

In rotating electrical equipment, Ring Sintered NdFeB magnets function as the primary magnetic field source. When integrated into synchronous motors or generators:

-

The ring magnet produces a stable magnetic field aligned with the rotor or stator structure

-

Interaction between the permanent magnetic field and alternating current generates torque

-

Radial or axial magnetization patterns control magnetic flux direction and efficiency

Compared with segmented block magnets, ring-shaped sintered NdFeB enables more uniform flux distribution and reduced magnetic leakage, improving system stability and efficiency.

Material Composition and Manufacturing Technology

Ring Sintered NdFeB magnets are primarily composed of:

-

Neodymium (Nd)

-

Iron (Fe)

-

Boron (B)

-

Optional heavy rare earth elements (such as Dy or Tb) for temperature resistance

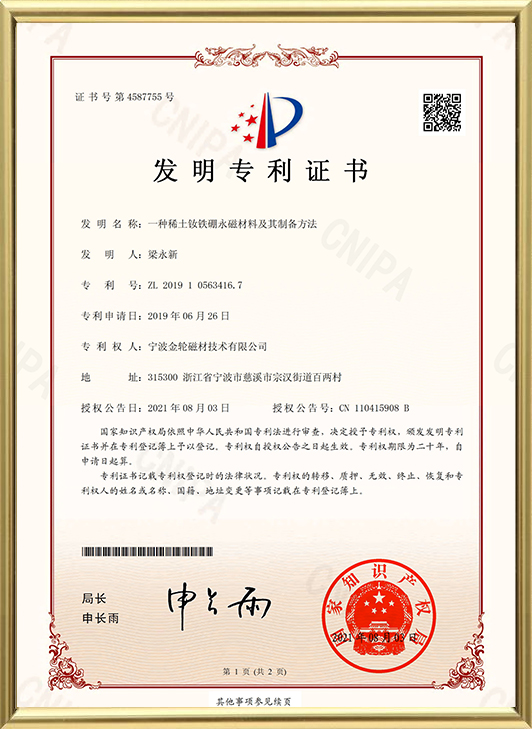

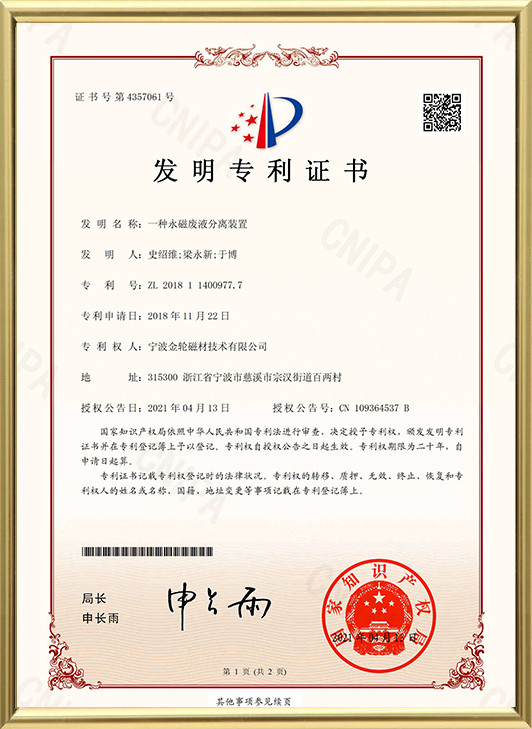

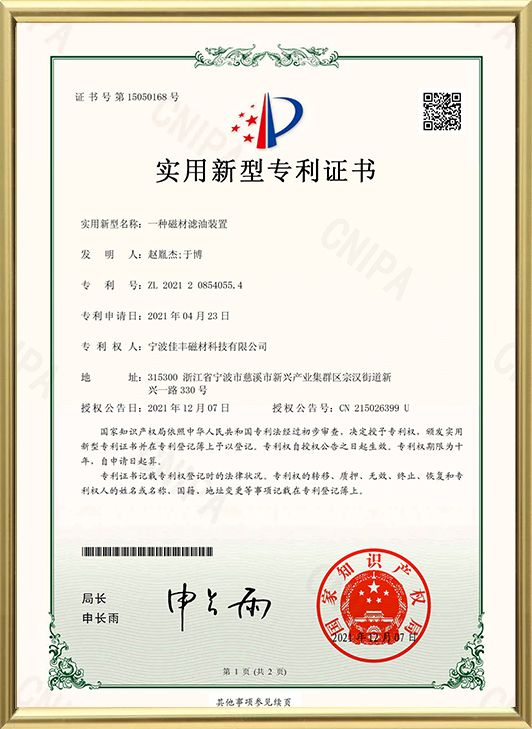

The manufacturing process includes powder preparation, magnetic field alignment, pressing, high-temperature sintering, precision machining, and surface coating. Ningbo Jinlun Magnet Technology Co., Ltd. utilizes advanced permanent magnet production equipment to ensure consistent magnetic orientation and dimensional accuracy across large production volumes.

Common surface coatings include:

-

Nickel (Ni-Cu-Ni)

-

Epoxy resin

-

Zinc

-

Phosphate coatings

Typical Applications and Use Cases

Ring Sintered NdFeB magnets are widely used in:

-

Permanent magnet synchronous motors (PMSM)

-

Servo motors and stepper motors

-

Wind power generators

-

Electric vehicle drive systems

-

Industrial automation equipment

-

Magnetic couplings and encoders

-

Medical and precision instruments

For example, in high-efficiency synchronous motors, Ring Sintered NdFeB magnets help achieve compact motor design while maintaining high torque density and reduced energy loss.

Customization and Engineering Support

Ring Sintered NdFeB magnets can be customized in:

-

Inner and outer diameters

-

Thickness and tolerances

-

Magnetization direction (radial, axial, multi-pole)

-

Magnetic grades and temperature ratings

Ningbo Jinlun Magnet Technology Co., Ltd., with over 30 years of industry experience and an annual capacity of 8,000 tons, supports customized Ring Sintered NdFeB solutions for synchronous motor manufacturers and industrial equipment producers.

Frequently Asked Questions (FAQ)

Q1: What magnetization types are available for Ring Sintered NdFeB magnets?

A: Common options include radial magnetization, axial magnetization, and multi-pole magnetization, depending on motor design requirements.

Q2: Are Ring Sintered NdFeB magnets suitable for high-temperature environments?

A: Yes, specific grades with added heavy rare earth elements can operate reliably at elevated temperatures.

Q3: How does ring geometry improve motor performance?

A: Ring geometry provides continuous magnetic paths, reducing flux leakage and improving torque consistency.

Q4: Can Ring Sintered NdFeB magnets be used in high-speed motors?

A: With proper mechanical reinforcement and material selection, they are suitable for high-speed rotating systems.

Q5: What coatings are recommended for corrosion resistance?

A: Nickel and epoxy coatings are commonly used depending on environmental conditions.

EN

EN English

English 中文简体

中文简体 русский

русский Deutsch

Deutsch 日本語

日本語 한국어

한국어