What Is the Difference Between a Sintered NdFeB Magnet and a Regular Magnet?

With the rapid development of electronics, automotive systems, and renewable energy technologies, magnets play a more critical role than ever before. Among various magnetic materials, the Sintered NdFeB Magnet stands out for its exceptional performance. But how does it differ from a regular magnet? Understanding these differences helps engineers, buyers, and manufacturers choose the right magnetic solution for their applications.

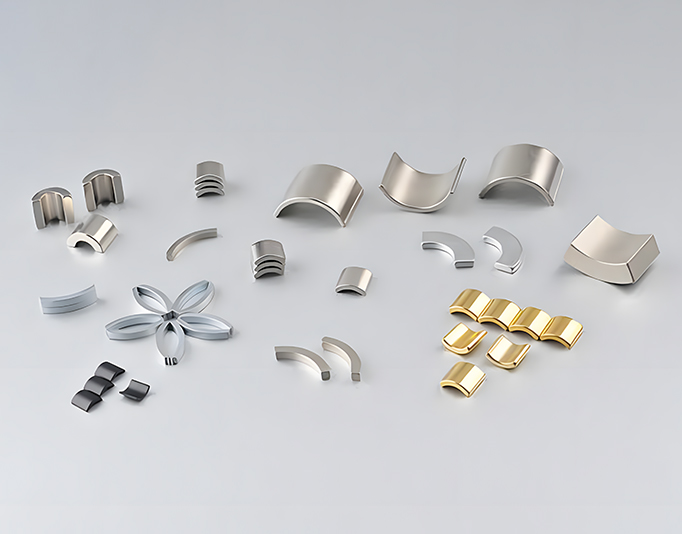

Click to visit our products:Sintered NdFeB Magnet

Understanding Sintered NdFeB Magnet

A Sintered NdFeB Magnet, also known as a sintered neodymium iron boron magnet, is a type of rare-earth permanent magnet made primarily from neodymium (Nd), iron (Fe), and boron (B). It is produced through a powder metallurgy process that includes melting, milling, pressing, sintering, and precision machining.

Key Characteristics of Sintered NdFeB Magnet

- Extremely high magnetic strength compared with conventional magnets

- Excellent energy product (BHmax), enabling compact and lightweight designs

- Strong coercivity, resisting demagnetization

- Widely used in high-performance and precision applications

What Is Considered a Regular Magnet?

The term “regular magnet” usually refers to traditional magnetic materials such as ferrite (ceramic) magnets or AlNiCo magnets. These magnets have been used for decades and remain common in low-cost or non-critical applications.

Common Types of Regular Magnets

- Ferrite (Ceramic) Magnets – inexpensive, corrosion-resistant, but relatively weak

- AlNiCo Magnets – stable at high temperatures but low resistance to demagnetization

- Flexible Magnets – made with magnetic powder and rubber or plastic binders

Sintered NdFeB Magnet vs Regular Magnet: Key Differences

1. Magnetic Strength

The most significant difference lies in magnetic performance. A Sintered NdFeB Magnet can be several times stronger than a ferrite magnet of the same size, making it ideal for compact and high-efficiency designs.

2. Size and Weight

Due to its high energy density, a Sintered NdFeB Magnet can achieve the same magnetic force with a much smaller volume. Regular magnets often require larger sizes to deliver similar performance.

3. Temperature Resistance

Regular magnets like AlNiCo perform well at high temperatures, while standard NdFeB magnets have lower temperature tolerance. However, advanced Sintered NdFeB Magnet grades are engineered to withstand elevated temperatures up to 200°C or higher.

4. Cost and Material Availability

Regular magnets are generally more affordable and widely available. Sintered NdFeB Magnet production involves rare-earth elements and complex manufacturing processes, resulting in higher costs.

5. Application Scope

- Sintered NdFeB Magnet: electric motors, wind turbines, electric vehicles, sensors, medical equipment

- Regular magnets: loudspeakers, household appliances, toys, simple holding applications

Comparison Table

- Magnetic Strength: Sintered NdFeB Magnet > Regular Magnet

- Size Efficiency: Sintered NdFeB Magnet is more compact

- Cost: Regular Magnet is more economical

- Performance Stability: Sintered NdFeB Magnet offers superior performance

Why Choose a Sintered NdFeB Magnet?

Industries requiring high efficiency, miniaturization, and reliability increasingly rely on Sintered NdFeB Magnet technology. From energy-saving motors to advanced automation systems, these magnets enable innovation that traditional magnets cannot support.

Frequently Asked Questions (FAQ)

Is a Sintered NdFeB Magnet stronger than a regular magnet?

Yes. A Sintered NdFeB Magnet offers significantly higher magnetic strength compared to ferrite or AlNiCo magnets of similar size.

Are Sintered NdFeB Magnets suitable for outdoor use?

They can be used outdoors if properly coated. Common surface treatments include nickel, epoxy, and zinc coatings to improve corrosion resistance.

Why are Sintered NdFeB Magnets more expensive?

The higher cost is due to rare-earth raw materials, complex manufacturing processes, and superior magnetic performance.

Can regular magnets replace Sintered NdFeB Magnets?

In low-performance or cost-sensitive applications, regular magnets may be sufficient. However, for compact, high-power, or precision systems, Sintered NdFeB Magnet solutions are often essential.

The difference between a Sintered NdFeB Magnet and a regular magnet goes far beyond strength alone. From efficiency and size to application versatility, sintered NdFeB technology continues to redefine what modern magnetic solutions can achieve.

News categories

Product categories

Exhibition Information

Jinlun Magnet specialized in the research and development, production, and sales of high-performance rare-earth permanent magnet materials.

-

Sales00@jlmagnet.com

Sales00@jlmagnet.com

-

+86-574-6321 2222

+86-574-6321 2222

-

No. 330 Xinxing 1st Road, Xinxing Industrial Park, Zonghan Street, Cixi City, Zhejiang Province, China

No. 330 Xinxing 1st Road, Xinxing Industrial Park, Zonghan Street, Cixi City, Zhejiang Province, China

Mobile QR Code

Copyright © Ningbo Jinlun Magnet Technology Co., Ltd. All Rights Reserved.

China sintered NdFeB magnet manufacturer wholesale sintered NdFeB magnet factory

EN

EN English

English 中文简体

中文简体 русский

русский Deutsch

Deutsch 日本語

日本語 한국어

한국어