Shape Sintered NdFeB refers to a range of neodymium iron boron permanent magnets manufactured through powder metallurgy sintering and precisely machined into various geometric forms. Products within this category share common material systems, magnetic performance characteristics, manufacturing processes, and application logic. Their primary function is to provide stable, controllable, and high-density magnetic fields for electromechanical equipment, energy systems, and precision devices.

With increasing demands for higher power density, compact system design, and improved energy efficiency, Shape Sintered NdFeB has become a key magnetic material solution in industrial and renewable energy applications.

Core Functions and Shared Performance Characteristics

The core function of Shape Sintered NdFeB is to deliver strong magnetic output and accurate magnetic circuit control through high magnetic energy density and directional magnetization. Key shared performance features include:

-

High remanence (Br), enabling strong magnetic flux in limited installation space

-

Stable intrinsic coercivity (Hcj), suitable for dynamic or alternating magnetic field conditions

-

A wide range of temperature resistance grades to meet different operating requirements

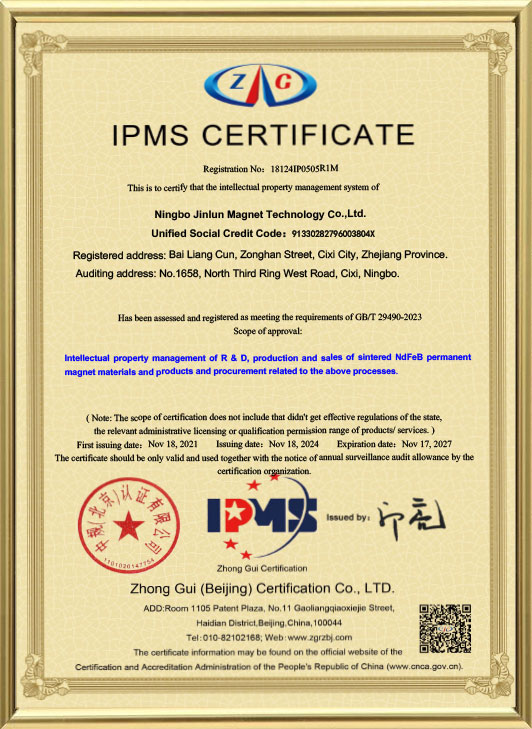

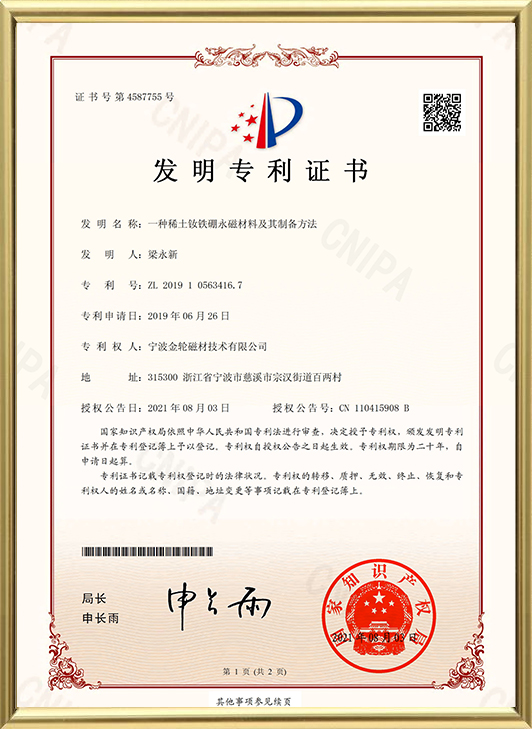

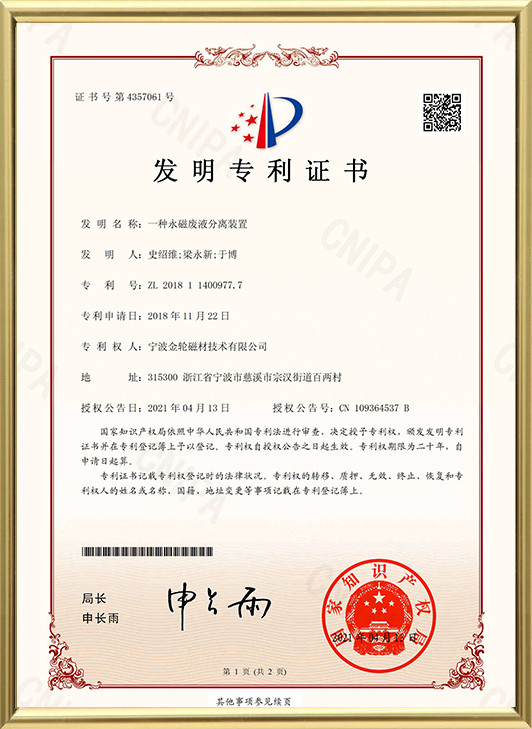

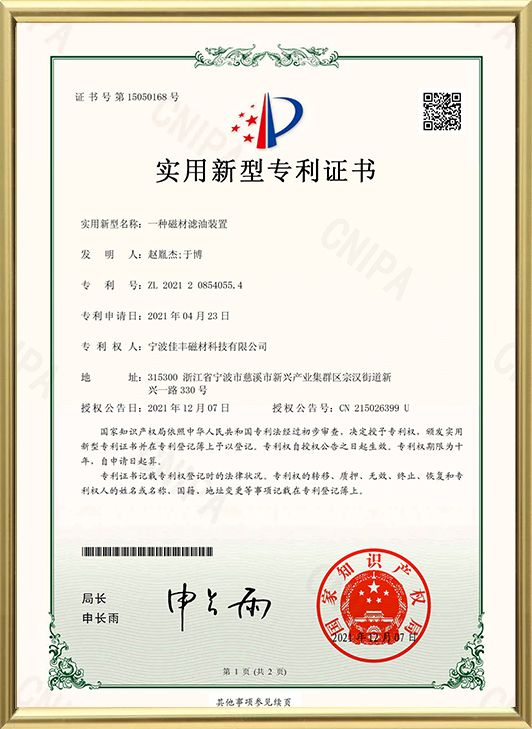

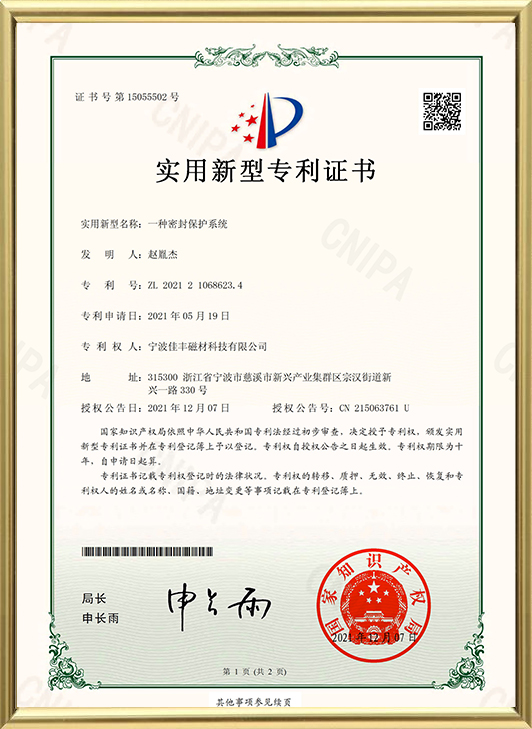

Ningbo Jinlun Magnet Technology Co., Ltd. applies mature control over magnetic composition, performance grading, and batch consistency, supporting reliable Shape Sintered NdFeB supply for large-scale industrial applications.

Operating Principles and Application Examples by Equipment Type

1. Motors and Drive Systems

Operating Principle: Shape Sintered NdFeB functions as the magnetic source in rotor or stator assemblies. Interaction between the permanent magnetic field and stator windings converts electrical energy into mechanical output.

Application Examples: New energy vehicle drive motors, industrial servo motors, brushless DC motors.

Technical Focus: High requirements for shape accuracy, radial or multi-pole magnetization, and thermal stability.

2. Power Generation and Energy Equipment

Operating Principle: Mechanical rotation causes magnetic field lines generated by Shape Sintered NdFeB to be cut by conductors, converting mechanical energy into electrical energy.

Application Examples: Wind turbines, small-scale power generation systems.

Technical Focus: Long-term magnetic stability and resistance to demagnetization.

3. Sensing and Control Devices

Operating Principle: Shape Sintered NdFeB provides a stable magnetic field that works with Hall sensors or magnetoresistive elements to detect position, speed, or angular changes.

Application Examples: Encoders, position sensors, industrial automation control modules.

Technical Focus: Magnetic field consistency and tight dimensional tolerances.

4. Medical and Precision Equipment

Operating Principle: Controlled magnetic fields are used to drive, position, or sense motion within compact and precision assemblies.

Application Examples: Medical pumps, precision actuators.

Technical Focus: Material reliability and surface protection performance.

Shape and Structural Design Characteristics

Shape Sintered NdFeB is commonly machined into discs, rings, blocks, arc segments, and customized complex geometries. Shape design directly affects magnetic field distribution, assembly methods, and system efficiency.

Through optimized structural design, magnetic flux paths can be improved within limited space, reducing leakage and enhancing overall equipment performance.

Comparative Analysis

| Comparison Item | Shape Sintered NdFeB | Bonded NdFeB | Ferrite Magnets |

|---|---|---|---|

| Magnetic Energy Density | High | Medium | Low |

| Dimensional Accuracy | High | High | Medium |

| Space Utilization | High | Medium | Low |

| Typical Applications | High-performance systems | Compact electronics | Cost-sensitive devices |

Compared with other magnet types, Shape Sintered NdFeB offers clear advantages in magnetic performance density and application adaptability.

Maintenance and Handling Guidelines

-

Avoid long-term exposure to high humidity or corrosive environments; select appropriate surface coatings when necessary

-

Prevent strong mechanical impact during installation and maintenance

-

Keep away from strong reverse magnetic fields to reduce the risk of partial demagnetization

-

Operate within the specified temperature range defined by the application design

Proper handling and maintenance help ensure long-term performance stability of Shape Sintered NdFeB.

Frequently Asked Questions (FAQ)

Q1: Can Shape Sintered NdFeB be customized for different equipment requirements?

A: Yes. Shape, magnetic performance grade, and magnetization method can be customized according to equipment design and operating principles.

Q2: Do different devices emphasize different magnetic properties?

A: Yes. Motors prioritize magnetic energy density and temperature resistance, while sensors focus on magnetic field stability and consistency.

Q3: How can the appropriate temperature grade be selected?

A: Selection should be based on continuous operating temperature, peak temperature, and required safety margins.

EN

EN English

English 中文简体

中文简体 русский

русский Deutsch

Deutsch 日本語

日本語 한국어

한국어