Sintered NdFeB Magnets for Wind Power are high-performance permanent magnets designed for use in wind turbine generators. These magnets are produced through a powder metallurgy sintering process that ensures high remanence, high coercivity, excellent thermal stability, and precise dimensional accuracy. They are critical for permanent magnet generators in both onshore and offshore wind turbines, where efficient energy conversion, reliability, and long-term performance are required.

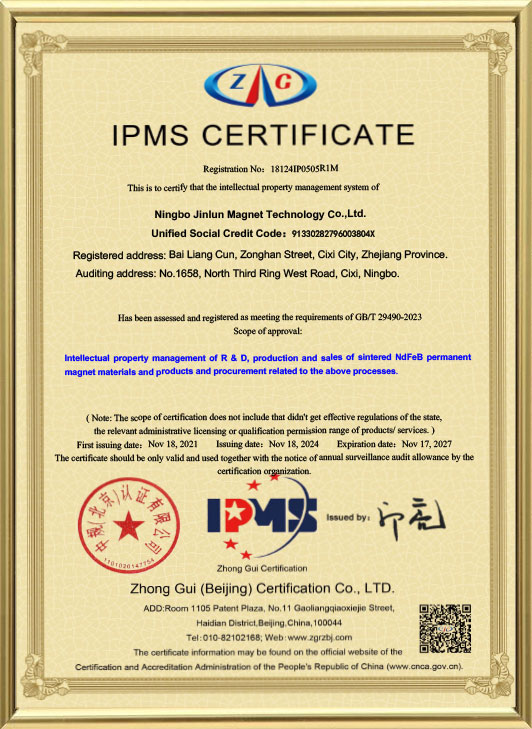

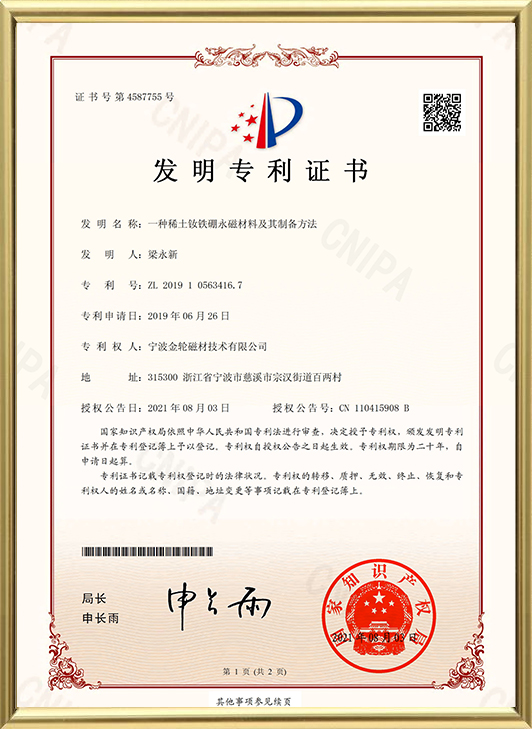

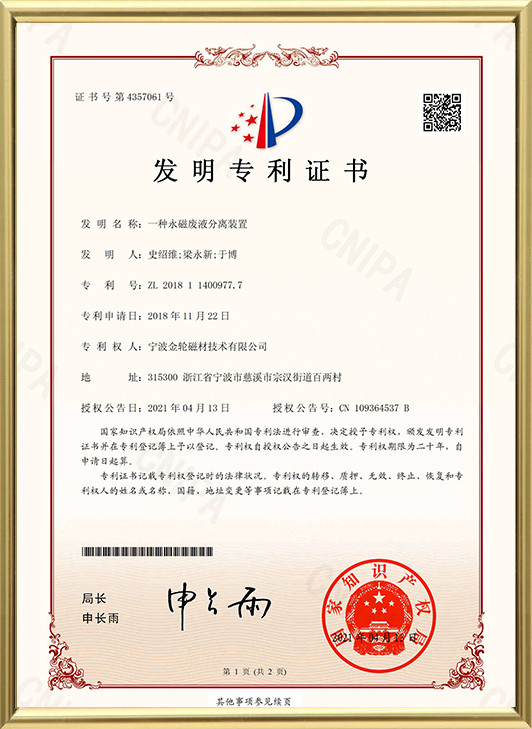

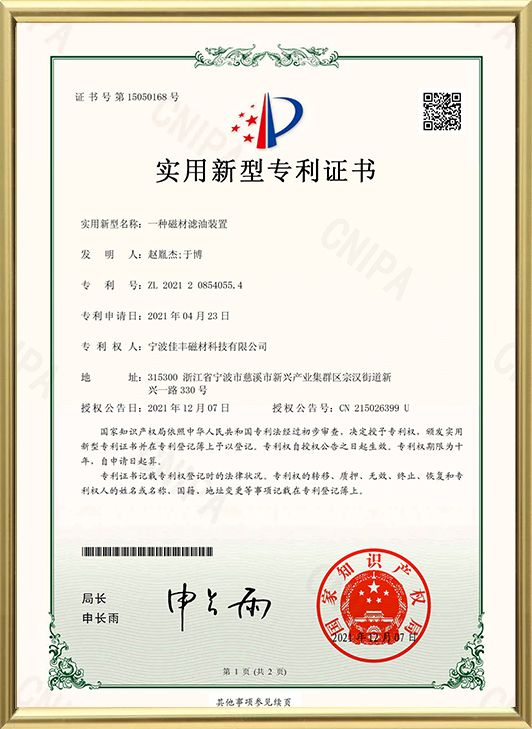

At Ningbo Jinlun Magnet Technology Co., Ltd., these magnets are manufactured with advanced international production equipment and rigorous quality control procedures. With over 30 years of experience, the company ensures consistent magnetic properties and high durability, supporting large-scale wind power applications and customized generator designs.

Core Functions and Features

Sintered NdFeB Magnets for Wind Power share several key characteristics:

-

High Magnetic Energy Density: Provides strong magnetic flux for high-efficiency energy conversion.

-

High Coercivity: Resists demagnetization from high temperature, vibration, and transient electrical loads.

-

Thermal and Mechanical Stability: Maintains performance under variable wind and environmental conditions.

-

Precision Manufacturing: Tight tolerances ensure rotor balance and efficient generator operation.

-

Long-Term Reliability: Stable performance over decades of operation in wind turbines.

These features make Sintered NdFeB Magnets essential for high-efficiency, long-life wind power generation systems.

Operating Principles in Wind Power Generators

Sintered NdFeB Magnets are used in permanent magnet synchronous generators (PMSG) in wind turbines:

-

Rotor Installation: Magnets are embedded in the rotor to produce a strong, stable magnetic field.

-

Electromagnetic Induction: As the rotor spins under wind force, the magnetic field induces electrical current in the stator coils.

-

Flux Optimization: High remanence and precise placement maximize energy conversion efficiency and reduce cogging torque.

-

Demagnetization Resistance: High coercivity prevents performance loss due to high temperature and electrical transients.

By providing a strong, stable magnetic field, Sintered NdFeB Magnets ensure efficient and reliable energy generation in wind turbines.

Typical Applications and Examples

1. Onshore Wind Turbines

Magnets in rotor assemblies of PMSG enable efficient electricity generation in medium- to large-scale onshore wind farms.

Example: 1.5 MW to 3 MW wind turbine generators.

2. Offshore Wind Turbines

Used in larger offshore turbines where long-term durability, high magnetic strength, and corrosion resistance are critical.

Example: 3 MW to 10 MW offshore PMSG systems.

3. Small Wind Turbines

Magnets support compact, high-efficiency generators for residential or industrial micro-wind applications.

4. Direct-Drive Generators

Sintered NdFeB Magnets are used in direct-drive designs to eliminate gearbox systems, improving efficiency and reducing maintenance.

Materials and Manufacturing Considerations

The production process for Sintered NdFeB Magnets for wind power involves:

-

Powder Preparation: High-purity Nd, Fe, B, and alloying elements are processed into fine powders.

-

Compaction: Pressed into precise shapes using high-precision dies.

-

Sintering: High-temperature sintering produces dense, uniform microstructure.

-

Magnetization: Magnets are magnetized according to generator design specifications.

-

Surface Coating: Corrosion-resistant coatings (Ni-Cu-Ni, epoxy, or specialized coatings) protect against marine or outdoor conditions.

At Ningbo Jinlun Magnet Technology Co., Ltd., strict quality control ensures uniform magnetic properties, precise dimensions, and long-term durability suitable for wind energy systems.

Maintenance and Usage Guidelines

To ensure long-term reliability of Sintered NdFeB Magnets in wind power applications:

-

Avoid mechanical shocks during rotor assembly.

-

Do not exceed the maximum operating temperature for the magnet grade.

-

Protect against strong external magnetic fields or electrical transients that may partially demagnetize magnets.

-

Inspect generator rotors and mounting structures periodically to maintain alignment and balance.

-

Ensure corrosion protection coatings are maintained, especially in offshore environments.

Proper installation and preventive maintenance extend performance and reduce downtime in wind power systems.

Frequently Asked Questions (FAQ)

Q1: Are Sintered NdFeB Magnets necessary for all wind turbines?

A: They are ideal for high-efficiency, direct-drive, and medium- to large-scale PMSG systems. Smaller turbines may use ferrite or bonded magnets.

Q2: Can magnet sizes and grades be customized for specific generator designs?

A: Yes, magnets can be manufactured in various shapes, sizes, and grades according to generator requirements.

Q3: What advantages do Sintered NdFeB Magnets have over ferrite or bonded magnets in wind power?

A: They provide higher magnetic strength, better coercivity, superior thermal stability, and compact size, supporting efficient, durable, and high-performance wind generators.

Conclusion

Sintered NdFeB Magnets for Wind Power deliver reliable, high-strength, and long-lasting magnetic solutions for modern wind energy systems. Leveraging over 30 years of manufacturing experience and advanced production equipment, Ningbo Jinlun Magnet Technology Co., Ltd. provides high-performance magnets for onshore, offshore, and small-scale turbines, ensuring efficiency, durability, and long-term reliability in wind power generation.

EN

EN English

English 中文简体

中文简体 русский

русский Deutsch

Deutsch 日本語

日本語 한국어

한국어