Sintered NdFeB magnets for medical apparatus are high-performance permanent magnets widely used in various medical devices due to their strong magnetic energy, stability, and precision. These magnets are primarily composed of neodymium (Nd), iron (Fe), and boron (B), offering superior remanence, coercivity, and energy density compared to other permanent magnets. Within medical applications, sintered NdFeB magnets are utilized in imaging equipment, therapeutic devices, diagnostic tools, and surgical instruments, providing consistent magnetic performance critical for both patient care and equipment reliability.

Applications and Device Principles

-

Magnetic Resonance Imaging (MRI) Systems

-

Principle: MRI systems rely on a strong, uniform magnetic field generated by NdFeB magnets to align hydrogen nuclei in the body, which are then detected using radiofrequency pulses to form detailed images.

-

Application Case: Hospitals use NdFeB-based MRI magnets to improve imaging resolution and reduce scanning time, particularly for brain and spinal examinations.

-

Maintenance Guidance: Ensure consistent temperature control and protect the magnet from mechanical shocks or demagnetizing fields to maintain long-term field stability.

-

-

Magnetic Therapy Devices

-

Principle: NdFeB magnets produce localized magnetic fields that can influence blood flow and cellular activity, supporting pain relief and recovery.

-

Application Case: Portable magnetic therapy equipment employs NdFeB magnets embedded in braces, mattresses, or wearable patches.

-

Maintenance Guidance: Avoid exposure to high temperatures and corrosive fluids; periodic inspection for magnetic strength and surface integrity is recommended.

-

-

Magnetic Separators and Surgical Tools

-

Principle: NdFeB magnets in surgical instruments allow precise manipulation of metallic fragments or guidance of magnetically tagged tools in minimally invasive procedures.

-

Application Case: Magnetic surgical clamps and retrieval devices enhance operational precision in orthopedic or endoscopic procedures.

-

Maintenance Guidance: Clean after each use with non-corrosive solutions and verify magnet alignment to ensure consistent performance.

-

Comparisons with Other Magnetic Materials

| Feature | Sintered NdFeB | Ferrite Magnets | AlNiCo Magnets |

|---|---|---|---|

| Maximum Energy Product | 35–55 MGOe | 3–5 MGOe | 5–10 MGOe |

| Coercivity | High | Medium | Low |

| Temperature Stability | Moderate (can be improved with coatings/alloying) | High | Very High |

| Typical Medical Applications | MRI, magnetic therapy, surgical tools | Limited use | Some diagnostic tools |

Sintered NdFeB magnets are preferred in modern medical devices where compact size, high field strength, and precision are required. Their energy density allows for smaller magnet assemblies, reducing device footprint compared to ferrite or AlNiCo magnets.

Maintenance and Handling Considerations

-

Environmental Control: Avoid exposure to high humidity, strong acids, or temperatures exceeding the magnet’s maximum operating range.

-

Mechanical Protection: NdFeB magnets are brittle; proper casing or encapsulation is essential to prevent chipping or cracking.

-

Demagnetization Prevention: Keep away from other strong magnetic fields or electrical devices that could alter magnetization.

FAQ

-

Q: Can NdFeB magnets be used in portable medical devices?

A: Yes, due to their high magnetic energy density, NdFeB magnets are suitable for compact portable devices, provided temperature and corrosion controls are in place. -

Q: How long do NdFeB magnets last in medical applications?

A: With proper handling and environmental protection, their operational life can exceed 10–15 years. -

Q: How do NdFeB magnets compare with ferrite in MRI systems?

A: NdFeB provides significantly higher field strength and allows for smaller magnet assemblies, while ferrite magnets are larger and weaker, limiting imaging resolution.

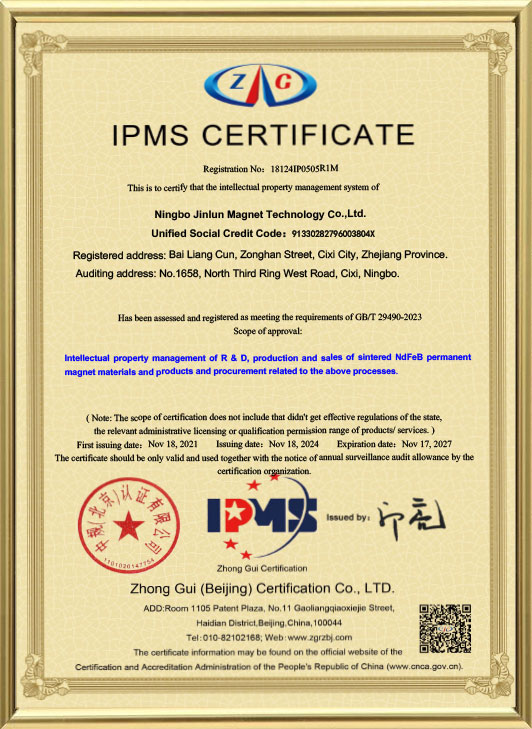

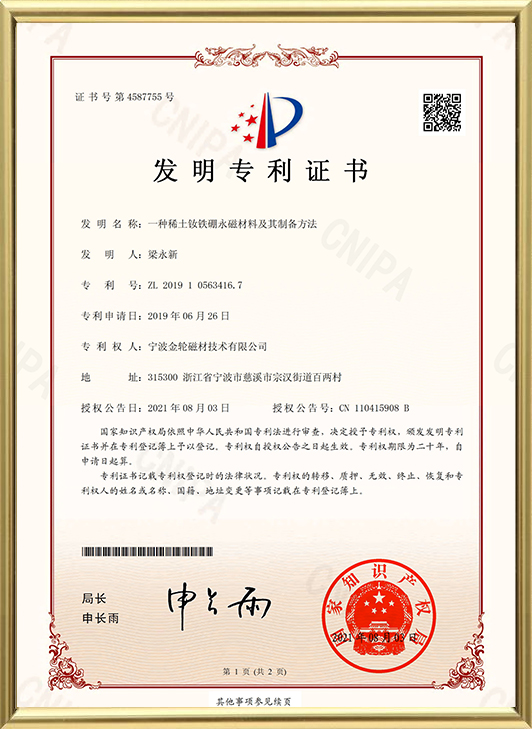

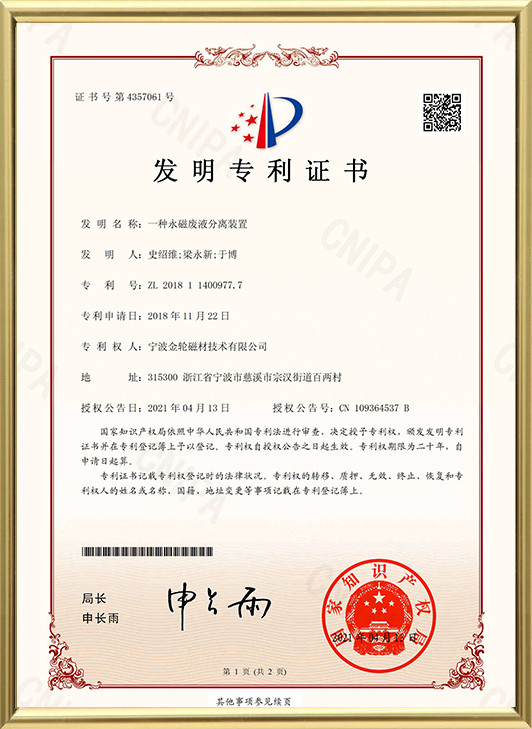

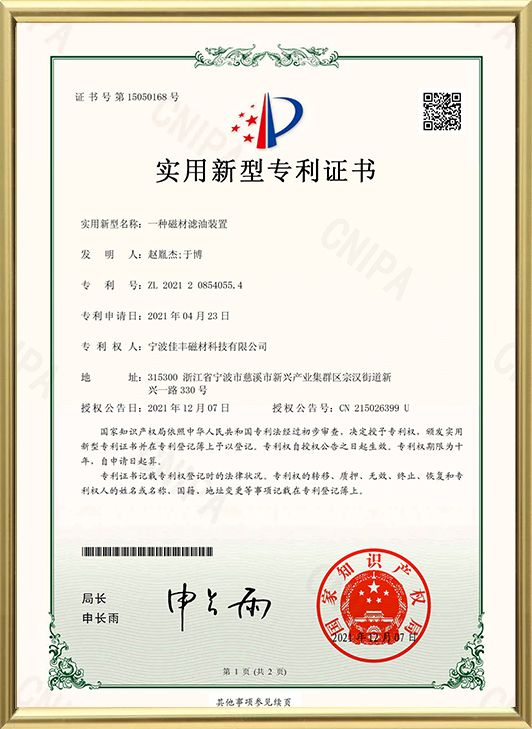

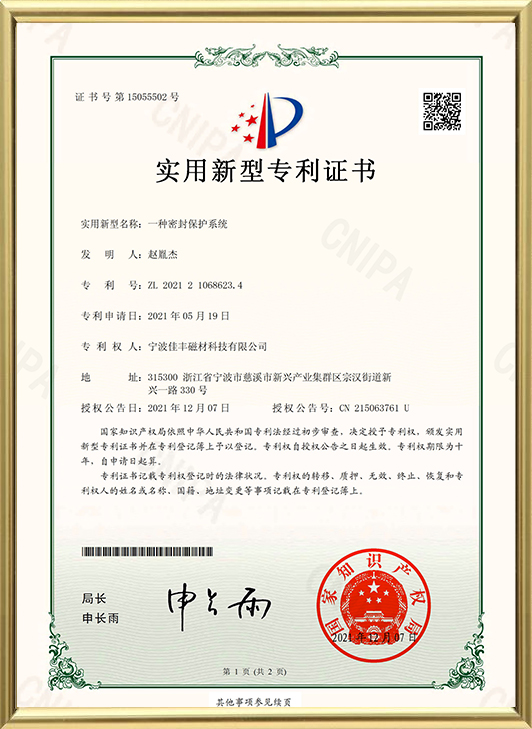

Ningbo Jinlun Magnet Technology Co., Ltd. produces high-performance sintered NdFeB magnets specifically designed for medical apparatus applications. With over 30 years of industry experience and advanced production equipment, Jinlun Magnet ensures consistent magnetic properties, precise tolerances, and reliable quality for medical manufacturers worldwide. Their NdFeB magnets support a wide range of medical devices, from imaging systems to therapeutic and surgical instruments, meeting rigorous performance and safety standards.

EN

EN English

English 中文简体

中文简体 русский

русский Deutsch

Deutsch 日本語

日本語 한국어

한국어