Sintered NdFeB magnets for the aerospace field are high-performance permanent magnets widely applied in aerospace engineering due to their high magnetic energy, stability, and precision. These magnets are composed primarily of neodymium (Nd), iron (Fe), and boron (B), offering superior remanence, coercivity, and energy density. Within aerospace applications, sintered NdFeB magnets are utilized in actuators, sensors, satellite systems, propulsion devices, and guidance mechanisms, where reliable magnetic performance under extreme environmental conditions is critical.

Applications and Device Principles

-

Aerospace Actuators and Motors

-

Principle: NdFeB magnets generate strong magnetic fields that interact with electric currents to produce torque in precision motors and actuators, which are critical for flight control surfaces, satellite orientation, and robotic arms.

-

Application Case: Small satellite reaction wheels and aircraft servo motors rely on NdFeB magnets for high torque-to-weight ratios.

-

Maintenance Guidance: Ensure the operating temperature remains within specified limits; periodic inspection for alignment and surface integrity is recommended to maintain performance.

-

-

Magnetic Sensors and Instrumentation

-

Principle: NdFeB magnets create consistent magnetic fields for position and rotational sensors, enabling accurate navigation, flight control, and telemetry systems.

-

Application Case: Aerospace gyroscopes and Hall effect sensors employ NdFeB magnets to improve measurement precision in satellite and aircraft navigation systems.

-

Maintenance Guidance: Protect from vibration and mechanical shock; ensure the sensor’s magnetic field remains stable over time to avoid drift.

-

-

Satellite Propulsion and Magnetic Control Devices

-

Principle: NdFeB magnets are used in magnetorquers and magnetic attitude control systems to interact with Earth’s magnetic field for satellite orientation adjustments.

-

Application Case: Low Earth Orbit (LEO) satellites utilize NdFeB-based magnetorquers to reduce fuel consumption and improve long-term stability.

-

Maintenance Guidance: Avoid exposure to high radiation flux and extreme temperatures; verify magnetic field strength periodically to ensure system reliability.

-

Comparisons with Other Magnetic Materials

| Feature | Sintered NdFeB | Ferrite Magnets | SmCo Magnets |

|---|---|---|---|

| Maximum Energy Product | 35–55 MGOe | 3–5 MGOe | 20–32 MGOe |

| Coercivity | High | Medium | Very High |

| Temperature Stability | Moderate (can be improved with coatings/alloying) | High | Excellent |

| Typical Aerospace Applications | Actuators, sensors, satellite systems | Limited use in low-demand instruments | High-temperature motors, aerospace control systems |

Sintered NdFeB magnets are preferred for aerospace applications where high magnetic strength and compact size are essential. Compared to ferrite magnets, NdFeB provides stronger fields with smaller volume, while SmCo magnets offer higher thermal stability at elevated temperatures but at higher material costs.

Maintenance and Handling Considerations

-

Environmental Control: Avoid exposure to extreme temperatures beyond the magnet’s rated limits, high humidity, or corrosive chemicals.

-

Mechanical Protection: NdFeB magnets are brittle; protective casing or coating is essential to prevent chipping or cracking.

-

Demagnetization Prevention: Keep away from strong external magnetic fields or unintended electrical currents.

FAQ

-

Q: Can NdFeB magnets maintain performance under extreme aerospace conditions?

A: Yes, provided temperature limits, vibration, and environmental exposure are controlled, NdFeB magnets retain high performance and stability. -

Q: How do NdFeB magnets compare to SmCo in aerospace applications?

A: NdFeB offers higher magnetic energy and smaller size, while SmCo provides superior temperature stability; selection depends on mission-specific thermal requirements. -

Q: What is the typical lifespan of NdFeB magnets in satellite systems?

A: With proper design and protection, NdFeB magnets can function reliably for decades in aerospace systems.

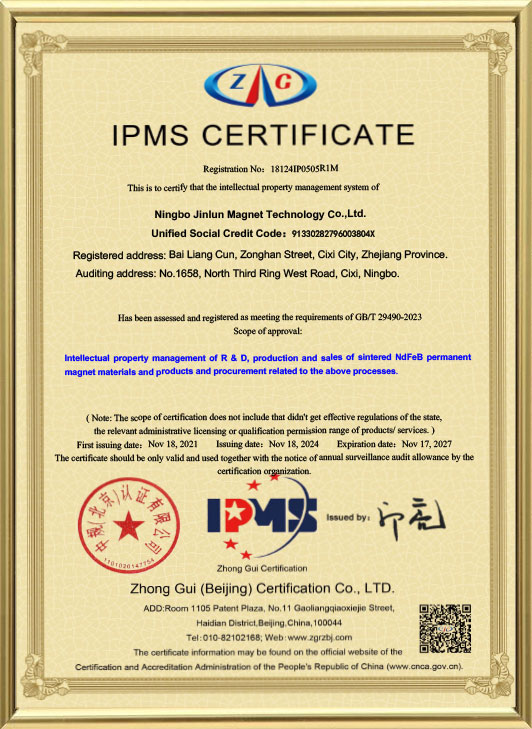

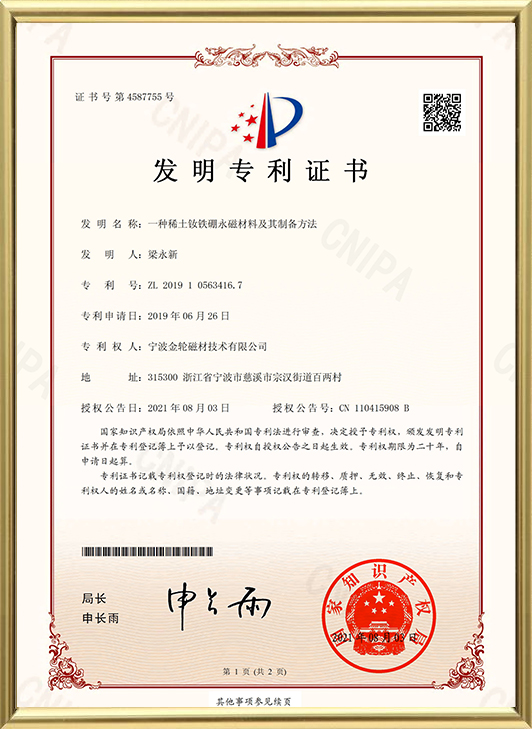

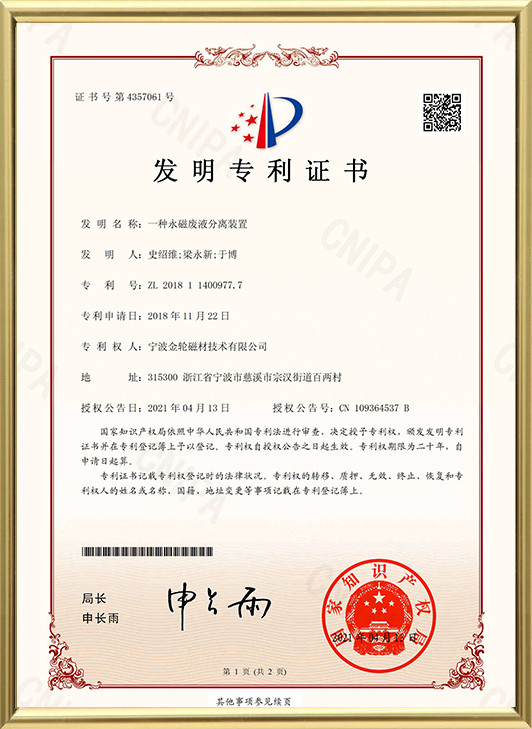

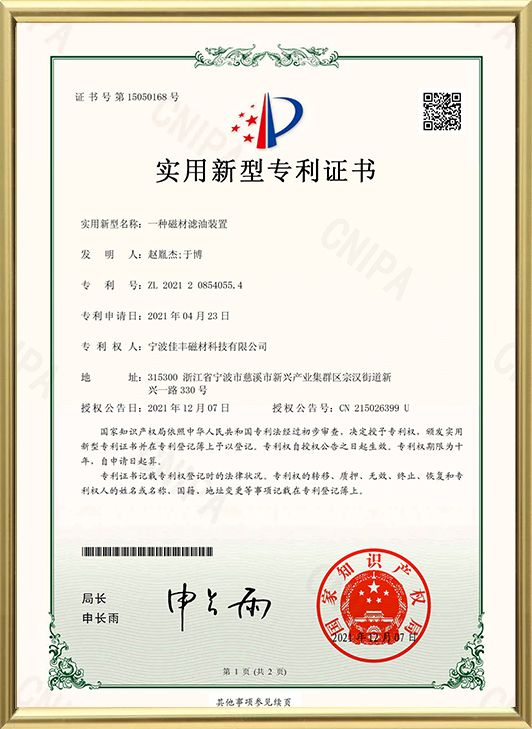

Ningbo Jinlun Magnet Technology Co., Ltd. manufactures high-performance sintered NdFeB magnets suitable for aerospace applications. Leveraging over 30 years of experience and advanced international production equipment, Jinlun Magnet ensures precise magnetic properties, dimensional accuracy, and reliable quality for aerospace components, supporting applications in actuators, sensors, propulsion, and guidance systems.

EN

EN English

English 中文简体

中文简体 русский

русский Deutsch

Deutsch 日本語

日本語 한국어

한국어