Magnetic Energy Density as the Core: What Magnetic Strength Must a Neodymium Magnet Possess to Adapt to Industrial Scenarios?

In cross-border industrial procurement, the magnetic energy density of a Neodymium Magnet is the core indicator determining its application value. As one of the permanent magnet materials with the highest commercialized energy product currently available, the energy product (BHmax) of a Neodymium Magnet typically ranges from 28 to 52 MGOe, far exceeding that of traditional magnets such as ferrite and AlNiCo. It can generate extremely strong attraction and repulsion within a limited volume. Industrial scenarios have strict requirements for space utilization—for example, miniaturization and lightweight design are core trends in equipment such as motors, sensors, and medical devices. A Neodymium Magnet with high magnetic energy density can improve key performances such as power output and signal sensitivity without increasing the equipment volume. During procurement, it is necessary to select an appropriate energy product grade based on specific working conditions to ensure that the Neodymium Magnet not only meets power or adsorption needs but also avoids installation difficulties or energy waste caused by excessive magnetic force. This is also the primary consideration when selecting a Neodymium Magnet in cross-border industrial procurement.

Environmental Stability is Key: What Damage Resistance Must a Neodymium Magnet Have to Cope with Complex Working Conditions?

Neodymium Magnets purchased through cross-border industrial channels need to adapt to diverse industrial environments in different countries and regions, and their environmental stability directly affects the service life and operational safety of equipment. Essentially, Neodymium Magnets are prone to corrosion and temperature influences, so compliant industrial-grade products must have reliable protective designs and temperature resistance. In terms of corrosion resistance, high-quality Neodymium Magnets usually adopt zinc (Zn) plating, nickel (Ni) plating, copper (Cu) plating, or epoxy resin coatings, which can resist corrosive factors in industrial environments such as moisture and acid-base gases, preventing the attenuation of magnetic performance due to oxidation. Regarding temperature adaptability, industrial-grade Neodymium Magnets are classified into different grades—for example, regular grades (N35-N52) can withstand 80℃, while high-temperature-resistant grades (such as N35SH and N42UH) can work stably in environments of 120-150℃, meeting the needs of high-temperature scenarios such as automotive engines and industrial furnaces. This strong environmental adaptability makes Neodymium Magnets a core choice for adapting to multiple working conditions in cross-border industrial procurement.

Click to visit our products: Neodymium Magnets

Mechanical Performance Adaptation: What Structural Characteristics Must a Neodymium Magnet Have to Meet Industrial Installation Requirements?

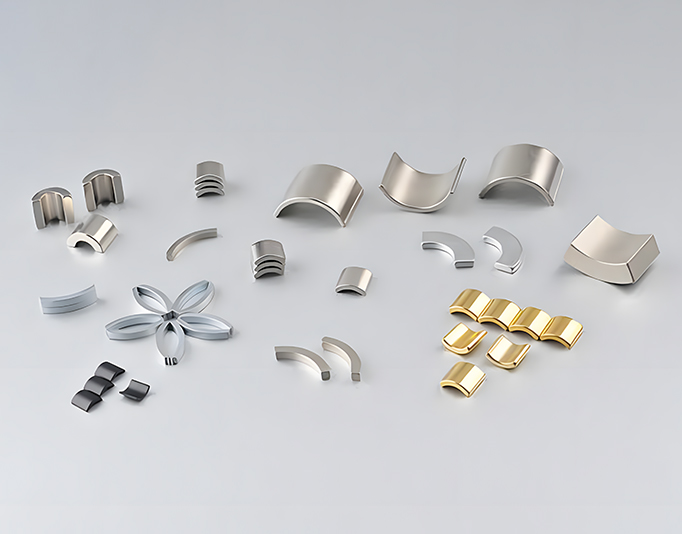

There are various installation methods in industrial scenarios, which put forward clear requirements for the mechanical performance and structural design of Neodymium Magnets—this is also an unignorable feature in cross-border procurement. Neodymium Magnets themselves are relatively brittle and have weak impact and shear resistance, so industrial-grade products need to improve practicality through reasonable structural optimization. For example, integrated molding technology is used to enhance structural strength, or customized shapes such as blocks, cylinders, rings, and tiles are designed according to installation needs to adapt to different methods such as bolt fixing and embedded installation. At the same time, the dimensional accuracy of Neodymium Magnets is crucial—industrial-grade products must have a tolerance controlled within the range of ±0.01-±0.1mm to ensure precise fit with equipment components and avoid operational noise, performance loss, and other issues caused by assembly gaps. The adaptability of these mechanical properties allows Neodymium Magnets to seamlessly integrate into the production and assembly processes of various industrial equipment, becoming reliable components in cross-border procurement.

Compliance Certifications are Indispensable: Which International Standards Must a Neodymium Magnet Meet for Cross-Border Circulation?

Cross-border industrial procurement involves trade rules and safety standards of multiple countries, and the compliance of Neodymium Magnets is a prerequisite for smooth customs clearance and legal use. Firstly, as rare earth permanent magnet materials, Neodymium Magnets must comply with the rare earth resource control policies of exporting and importing countries, such as the EU’s REACH Regulation and relevant EPA standards in the United States, which restrict the content of hazardous substances and ensure the environmental friendliness of resource extraction and production processes. Secondly, for electrical and electronic industrial products, Neodymium Magnets must meet the requirements of the RoHS Directive to avoid excessive levels of hazardous substances such as lead and cadmium, safeguarding environmental safety and human health during equipment use. In addition, some Neodymium Magnets used in high-end industrial fields such as aerospace and medical devices also need to pass certifications such as the ISO 9001 quality management system certification and the Medical Device Quality Management System Certification (ISO 13485) to prove their performance stability and reliability. These compliance certifications are not only "passes" for cross-border trade but also important bases for selecting high-quality Neodymium Magnets in industrial procurement.

Long-Term Magnetic Stability: What Demagnetization Resistance Must a Neodymium Magnet Have to Ensure Long-Term Use?

The service life of industrial equipment usually lasts for several years or even more than a decade, and the magnetic stability (i.e., demagnetization resistance) of Neodymium Magnets directly affects the long-term operational effect of equipment, making it one of the core considerations in cross-border industrial procurement. High-quality Neodymium Magnets must have an extremely low coercivity (Hcj) attenuation rate, controlling magnetic flux loss within a very small range (usually an annual attenuation rate of less than 1%) under conditions such as long-term use, temperature fluctuations, and external magnetic field interference. This feature is crucial for industrial scenarios relying on stable magnetic force—for example, permanent magnet rotors of wind turbines, braking systems of elevators, and adsorption devices of automated production lines. If a Neodymium Magnet experiences significant demagnetization, it may lead to reduced equipment efficiency and increased safety hazards. During procurement, attention should be paid to the coercivity parameters of the Neodymium Magnet (usually requiring Hcj>12 kOe) and magnetic stability test reports to ensure that it maintains stable magnetic performance throughout the entire service life of the equipment, reducing subsequent maintenance and replacement costs.

Customization Potential: What Adaptability Must a Neodymium Magnet Have to Meet Diverse Industrial Needs?

There are significant differences in needs across different industrial fields, and the customization potential of Neodymium Magnets has become an important advantage in cross-border industrial procurement. Industrial-grade Neodymium Magnets can be precisely customized in terms of magnetic performance, size, shape, coating, etc., according to the specific needs of purchasers. For example, ring-shaped Neodymium Magnets with high power density are customized for new energy vehicle drive motors, miniaturized thin-sheet Neodymium Magnets for sensors, and special coating Neodymium Magnets with high corrosion resistance for marine engineering equipment. This high degree of customization allows Neodymium Magnets to adapt to the differentiated needs of multiple industrial fields such as machinery manufacturing, electrical and electronics, new energy, and aerospace. At the same time, customized production can also help purchasers optimize product design and enhance core competitiveness of equipment, which is one of the key reasons why Neodymium Magnets are highly favored in cross-border industrial procurement.

News categories

Product categories

Exhibition Information

Content

- 1 Environmental Stability is Key: What Damage Resistance Must a Neodymium Magnet Have to Cope with Complex Working Conditions?

- 2 Mechanical Performance Adaptation: What Structural Characteristics Must a Neodymium Magnet Have to Meet Industrial Installation Requirements?

- 3 Compliance Certifications are Indispensable: Which International Standards Must a Neodymium Magnet Meet for Cross-Border Circulation?

- 4 Long-Term Magnetic Stability: What Demagnetization Resistance Must a Neodymium Magnet Have to Ensure Long-Term Use?

- 5 Customization Potential: What Adaptability Must a Neodymium Magnet Have to Meet Diverse Industrial Needs?

Jinlun Magnet specialized in the research and development, production, and sales of high-performance rare-earth permanent magnet materials.

-

Sales00@jlmagnet.com

Sales00@jlmagnet.com

-

+86-574-6321 2222

+86-574-6321 2222

-

No. 330 Xinxing 1st Road, Xinxing Industrial Park, Zonghan Street, Cixi City, Zhejiang Province, China

No. 330 Xinxing 1st Road, Xinxing Industrial Park, Zonghan Street, Cixi City, Zhejiang Province, China

Mobile QR Code

Copyright © Ningbo Jinlun Magnet Technology Co., Ltd. All Rights Reserved.

China sintered NdFeB magnet manufacturer wholesale sintered NdFeB magnet factory

EN

EN English

English 中文简体

中文简体 русский

русский Deutsch

Deutsch 日本語

日本語 한국어

한국어