We Are Always Ready To Offer Quality Raw-material.

Stable Supply Chain Construction

Diversified supplier layout, establishment of a core supplier + backup supplier echelon system, and construction of regional and cross-border supply networks

Digital Empowerment

Intelligent supply chain system, implementation of ERP-SCM integrated management, use of IoT technology big data to predict supply and demand changes.

Customer Satisfaction Guarantee

Centralized procurement advantages, bargaining with scale effect, logistics cost sharing, upstream investment, and joint construction of industrial parks.

Renowned for our exceptional product quality, fast lead times, and high flexibility, we have become a trusted long-term partner for

prominent companies across multiple industries.

01 Complete Procurement System

Centralized Procurement Reduces Costs

Jinlun Magnetic Materials integrates the raw material demands of various production bases within the group to achieve centralized procurement of core materials, gaining price advantages through long-term stable procurement volumes, thereby reducing raw material costs.

Resource Cooperation

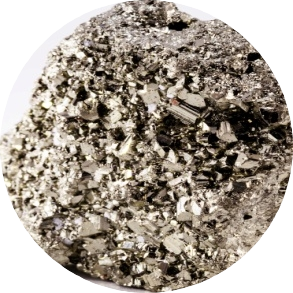

Sign strategic cooperation and long-term supply agreements with high-quality mines and smelting companies at home and abroad to avoid market price fluctuation risks. Stable and diversified raw material supply channels to maintain stable product prices, stable quality and stable supply. At the same time, deepen cooperation through advance payments, technical cooperation, etc., to ensure the stable supply and price advantages of key raw materials (such as praseodymium-neodymium alloys, dysprosium-iron alloys, etc.).

Supply Chain Vertical Integration

Extend upstream to the rare-earth separation and metal purification links, reduce the price difference of middlemen, lock in part of the raw material production capacity through the establishment of strategic cooperation, and enhance the bargaining power in raw material procurement.

02 Raw Material Supply Chain Quality Control

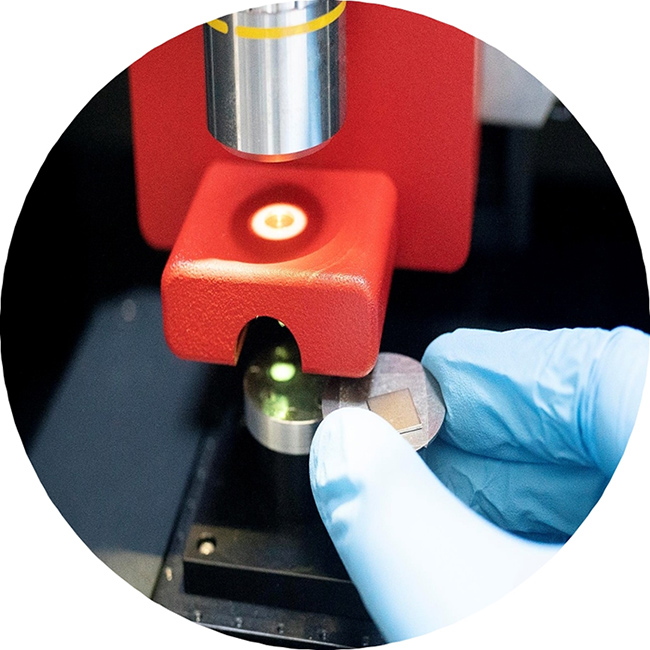

Raw Material Quality Testing Standards

Precise composition analysis

X-ray fluorescence spectrometer (XRF) and inductively coupled plasma mass spectrometer (ICP-MS) are used to test the purity and impurity content of rare-earth elements at the ppm level to ensure the magnetic stability of NdFeB magnets.

Physical Performance Test

Use high-precision equipment such as a particle size distribution analyzer and a specific surface area meter to accurately verify the uniformity of raw material particles, avoid sintering defects caused by uneven particle size, and ensure the consistency of magnet density and overall performance reliability.

Environmental Compliance Screening

Strictly implement RoHS (Restriction of Hazardous Substances Directive) and REACH (Registration, Evaluation, Authorization and Restriction of Chemicals) regulations, conduct trace-level detection of hazardous substances such as guide and cadmium, and ensure that products meet EU and North American market access standards.

Full-process Traceability Management SystemApplication of Information Technology

From rare-earth ore mining to final product delivery, the entire process is managed by blockchain. Each link (such as smelting, hydrogen crushing, and air flow grinding) generates a time-stamped, tamper-proof record and supports scanning to trace production batches and process parameters.

Supplier Dynamic Rating

Use the supplier dynamic rating system based on AI algorithm to evaluate the performance of 30+ suppliers in real time, covering 6 key indicators such as delivery on time rate and quality abnormality rate, automatically triggering a graded procurement strategy to reduce the risk of supply chain disruption.

Abnormal Closed Loop Mechanism

When the detection system finds that a batch of raw materials exceeds the standard, the system automatically freezes the related inventory and triggers the root cause analysis process. The complete closed loop from problem identification and location to formulation and real-time corrective measures is completed efficiently within 48 hours.

Military-grade Quality Control Laboratory

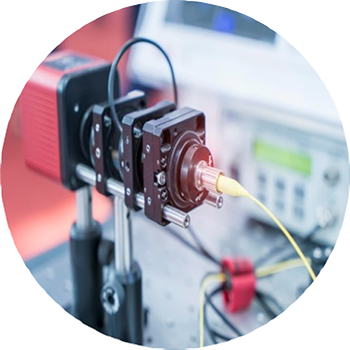

Magnetic Performance Limit Test

Equipped with a B-H hysteresis loop instrument and vibrating sample magnetometer (VSM), good environmental conditions are simulated in the temperature range of -60℃~200℃ to accurately verify the attenuation rate of key parameters such as remanence Br and coercivity Hcb ≤1.5%, ensuring the reliability of magnetic materials.

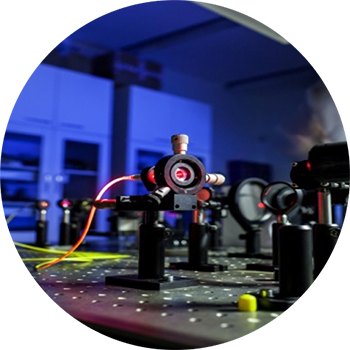

Microstructure Analysis

By combining high-end integrated scanning electron microscopy (SEM) and imported energy dispersive spectroscopy (EDS) technology, the distribution uniformity of heavy rare-earth elements during grain boundary diffusion is accurately detected to enhance and optimize the efficiency of improving the coercivity of magnets.

Accelerated Life Test

According to the MIL-STD-810G standard, a 1000-hour composite environmental test, including heat aging and mechanical vibration, is carried out to ensure that the magnetic flux loss rate in high-end motor application scenarios is less than 3% within ten years, verifying the long-term stability of the product.

03 Cost Control Advantage

High-value Element Recovery Rate is Improved

Using hydrometallurgy and vacuum distillation technology, rare-earth waste such as neodymium, dysprosium, and terbium generated during the production process is efficiently purified, with a recovery rate of more than 95%, which greatly reduces dependence on primary resources, while reducing environmental disposal costs and promoting sustainable use of resources.

Recycled Material Performance Meets Standards

Through patented waste reprocessing technology (such as hydrogen crushing and air flow mill classification), the coercive force and residual magnetic strength of recycled magnetic powder are guaranteed to be close to those of primary materials, which can be directly used in the production of medium and high-end magnets, realizing resource recycling and max. economic value.

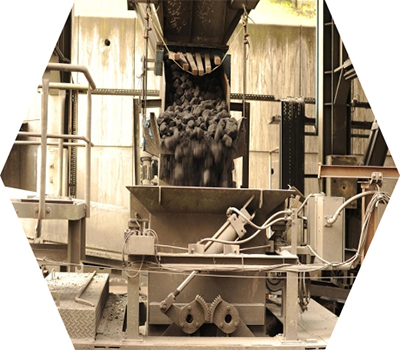

Zero Waste Emission System

Establish a full-chain waste collection system for magnetic material processing from metallurgy, cutting, grinding to electroplating, equipped with advanced automated sorting and smelting equipment, forming a closed-loop ecology of "production-recycling-reproduction", reducing the raw material procurement cost by 15%-20% each year, and realizing the max—utilization of resources and zero burden on the environment.

04 Sustainable Development Guarantee

Rare-earth Element Substitution R&D

Reduce dependence on scarce rare earth elements through technological innovation, promote material science progress and cost optimization.

High-abundance Rare-earth Application

Development of magnetic material formulas that use abundant elements such as lanthanum and cerium to replace scarce neodymium and dysprosium, and have achieved a 50% reduction in some motor products.

Non-Rare Earth Magnet Development

Jointly with the Chinese Academy of Sciences team to tackle samarium iron nitrogen permanent magnet materials, the magnetic energy product reached 30 MGOe.

Performance Compensation Technology

Through grain boundary diffusion process and microstructure control means, the high temperature resistance of the magnet is maintained while reducing the amount of heavy rare earth elements.

Circular Economy System

Construction of Closed-loop Recycling Network

●Successfully laid out a waste magnetic material recycling network covering the Yangtze River Delta, using a hydrogen crushing-re-sintering process to ensure that the performance of the recycled magnets is restored to more than 92% of the level of new materials.

●Reached a waste repurchase cooperation agreement with wind power and new energy vehicle companies, with an annual processing capacity of 100 tons, reducing the demand for primary rare earth mining by 10%.

Stable Supply of Raw-materials

Jinlun Magnet establishes a flexible, agile, and sustainable supply guarantee mechanism based on industry characteristics and its own development stage.

-

Production Workshop

-

Production Workshop

-

Production Workshop

-

Production Workshop

-

Production Workshop

-

Production Workshop

-

Factory Warehouse

-

Factory Warehouse

Product Manual

-

Synchronous Motor

Synchronous Motor

-

Consumer Electronics

Consumer Electronics

-

Automotive Field

Automotive Field

-

Wind Power

Wind Power

-

Medical Apparatus

Medical Apparatus

-

Aerospace field

Aerospace field

-

Magnetic Application

Magnetic Application

EN

EN English

English 中文简体

中文简体 русский

русский Deutsch

Deutsch 日本語

日本語 한국어

한국어