Home / Technical Parameters

product category

PDF Download

Technical Parameters

| Material | Main Magnetic Properties (Room Temperature 20℃) | |||||||||

| No. | Grade | Br | Hcj | Hcj | (BH)max | Maxmum Working Temperature ℃ | ||||

| T | kGs | kA/m | kOe | kA/m | kOe | kJ/m3 | MGOe | |||

| Minimum value | Minimum value | Minimum value | Range | |||||||

| 1 | N20 | 0.95 | 9.5 | 438 | 5.5 | 478 | 6 | 143~167 | 18~21 | 60 |

| 2 | N25 | 1 | 10 | 478 | 6 | 558 | 7 | 183~207 | 23~26 | 60 |

| 3 | N28 | 1.04 | 10.4 | 558 | 7 | 637 | 8 | 207~231 | 26~29 | 60 |

| 4 | N30 | 1.08 | 10.8 | 637 | 8 | 717 | 9 | 223~247 | 28~31 | 60 |

| 5 | N33 | 1.13 | 11.3 | 717 | 9 | 797 | 10 | 247~271 | 31~34 | 60 |

| 6 | N35 | 1.18 | 11.8 | 860 | 10.8 | 960 | 12 | 263~287 | 33~36 | 80 |

| 7 | N38 | 1.23 | 12.3 | 860 | 10.8 | 960 | 12 | 278~310 | 36~39 | 80 |

| 8 | N40 | 1.26 | 12.6 | 860 | 10.8 | 960 | 12 | 302~326 | 38~41 | 80 |

| 9 | N42 | 1.29 | 12.9 | 860 | 10.8 | 960 | 12 | 318~342 | 40~43 | 80 |

| 10 | N45 | 1.33 | 13.3 | 860 | 10.8 | 960 | 12 | 342~366 | 43~46 | 80 |

| 11 | N48 | 1.37 | 13.7 | 836 | 10.5 | 960 | 12 | 358~390 | 45~49 | 80 |

| 12 | N50 | 1.39 | 13.9 | 836 | 10.5 | 960 | 12 | 374~406 | 47~51 | 80 |

| 13 | N52 | 1.42 | 14.2 | 836 | 10.5 | 960 | 12 | 390~422 | 49~52 | 80 |

| 14 | N54 | 1.45 | 14.5 | 836 | 10.5 | 960 | 12 | 400~432 | 50~54 | 80 |

| 15 | N56 | 1.48 | 14.8 | 836 | 10.5 | 960 | 12 | 416~448 | 52~56 | 80 |

| 16 | N58 | 1.5 | 15 | 836 | 10.5 | 960 | 12 | 424~456 | 54~58 | 80 |

| 17 | 33M | 1.14 | 11.4 | 844 | 10.6 | 1114 | 14 | 239~263 | 30~33 | 100 |

| 18 | 35M | 1.18 | 11.8 | 860 | 10.8 | 1114 | 14 | 263~287 | 33~36 | 100 |

| 19 | 38M | 1.23 | 12.3 | 876 | 11 | 1114 | 14 | 287~310 | 36~39 | 100 |

| 20 | 40M | 1.26 | 12.6 | 910 | 11.4 | 1114 | 14 | 302~326 | 38~41 | 100 |

| 21 | 42M | 1.29 | 12.9 | 938 | 11.8 | 1114 | 14 | 318~342 | 40~43 | 100 |

| 22 | 45M | 1.33 | 13.3 | 971 | 12.2 | 1114 | 14 | 342~366 | 43~46 | 100 |

| 23 | 48M | 1.37 | 13.7 | 1012 | 12.7 | 1114 | 14 | 358~390 | 45~49 | 100 |

| 24 | 50M | 1.39 | 13.9 | 1035 | 13 | 1114 | 14 | 374~406 | 47~51 | 100 |

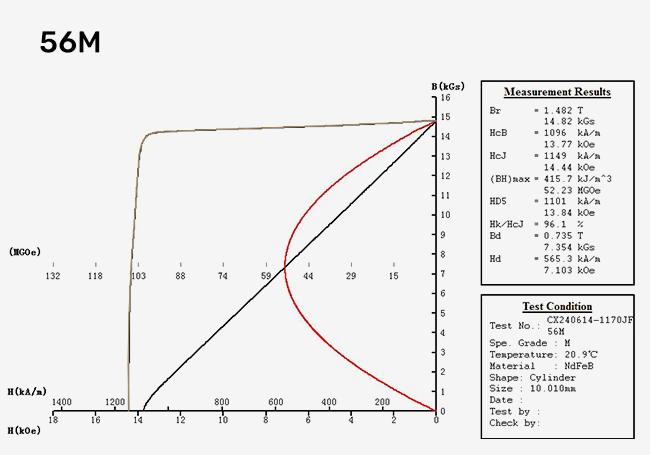

| 25 | 52M | 1.42 | 14.2 | 1035 | 13 | 1114 | 14 | 390~416 | 49~52 | 100 |

| 26 | 54M | 1.45 | 14.5 | 1035 | 13 | 1114 | 14 | 400~432 | 50~54 | 100 |

| 27 | 30H | 1.08 | 10.8 | 804 | 10.1 | 1353 | 17 | 223~248 | 28~31 | 120 |

| 28 | 33H | 1.14 | 11.4 | 844 | 10.6 | 1353 | 17 | 247~263 | 30~33 | 120 |

| 29 | 35H | 1.18 | 11.8 | 876 | 11 | 1353 | 17 | 263~287 | 33~36 | 120 |

| 30 | 38H | 1.23 | 12.3 | 910 | 11.4 | 1353 | 17 | 287~310 | 36~39 | 120 |

| 31 | 40H | 1.26 | 12.6 | 930 | 11.7 | 1353 | 17 | 302~326 | 38~41 | 120 |

| 32 | 42H | 1.29 | 12.9 | 957 | 12 | 1353 | 17 | 318~342 | 40~43 | 120 |

| 33 | 45H | 1.33 | 13.3 | 995 | 12.5 | 1353 | 17 | 342~366 | 43~46 | 120 |

| 34 | 48H | 1.37 | 13.7 | 1000 | 12.8 | 1353 | 17 | 358~390 | 45~49 | 120 |

| 35 | 50H | 1.39 | 13.9 | 1035 | 13 | 1353 | 17 | 374~406 | 47~51 | 120 |

| 36 | 52H | 1.42 | 14.2 | 1050 | 13.3 | 1274 | 16 | 390~422 | 49~53 | 120 |

| 37 | 54H | 1.45 | 14.5 | 1075 | 13.5 | 1274 | 16 | 406~438 | 51~55 | 120 |

| 38 | 30SH | 1.08 | 10.8 | 812 | 10.2 | 1592 | 20 | 223~248 | 28~31 | 150 |

| 39 | 33SH | 1.14 | 11.4 | 836 | 10.5 | 1592 | 20 | 247~271 | 31~34 | 150 |

| 40 | 35SH | 1.18 | 11.8 | 876 | 11 | 1592 | 20 | 263~287 | 33~36 | 150 |

| 41 | 38SH | 1.23 | 12.3 | 886 | 11.1 | 1592 | 20 | 287~310 | 36~39 | 150 |

| 42 | 40SH | 1.26 | 12.6 | 912 | 11.5 | 1592 | 20 | 302~326 | 38~41 | 150 |

| 43 | 42SH | 1.29 | 12.9 | 938 | 11.8 | 1592 | 20 | 318~342 | 40~43 | 150 |

| 44 | 45SH | 1.33 | 13.3 | 938 | 11.8 | 1592 | 20 | 342~366 | 43~46 | 150 |

| 45 | 48SH | 1.37 | 13.7 | 1035 | 12.8 | 1592 | 20 | 358~390 | 45~49 | 150 |

| 46 | 50SH | 1.39 | 13.9 | 1035 | 13 | 1592 | 20 | 374~406 | 47~51 | 150 |

| 47 | 52SH | 1.42 | 14.2 | 1059 | 13.3 | 1512 | 19 | 390~422 | 49~53 | 150 |

| 48 | 54SH | 1.45 | 14.5 | 1075 | 13.5 | 1512 | 19 | 406~438 | 51~55 | 150 |

| 49 | 30UH | 1.08 | 10.8 | 756 | 9.5 | 1990 | 25 | 223~247 | 28~31 | 180 |

| 50 | 33UH | 1.14 | 11.4 | 816 | 10.3 | 1990 | 25 | 247~271 | 31~34 | 180 |

| 51 | 35UH | 1.18 | 11.8 | 845 | 10.6 | 1990 | 25 | 263~287 | 33~36 | 180 |

| 52 | 38UH | 1.23 | 12.3 | 886 | 11.1 | 1990 | 25 | 287~310 | 36~39 | 180 |

| 53 | 40UH | 1.26 | 12.6 | 912 | 11.5 | 1990 | 25 | 302~326 | 38~41 | 180 |

| 54 | 42UH | 1.29 | 12.9 | 938 | 11.8 | 1990 | 25 | 318~342 | 40~43 | 180 |

| 55 | 45UH | 1.33 | 13.3 | 976 | 12.2 | 1911 | 24 | 342~366 | 43~46 | 180 |

| 56 | 48UH | 1.37 | 13.7 | 1019 | 12.8 | 1911 | 24 | 358~390 | 45~49 | 180 |

| 57 | 50UH | 1.39 | 13.9 | 1035 | 13 | 1911 | 24 | 374~406 | 47~51 | 180 |

| 58 | 28EH | 1.05 | 10.5 | 756 | 9.5 | 2388 | 30 | 207~231 | 26~29 | 200 |

| 59 | 30EH | 1.08 | 10.8 | 756 | 9.5 | 2387 | 30 | 223~247 | 28~31 | 200 |

| 60 | 33EH | 1.14 | 11.4 | 816 | 10.3 | 2387 | 30 | 247~271 | 31~34 | 200 |

| 61 | 35EH | 1.18 | 11.8 | 883 | 11.1 | 2387 | 30 | 236~287 | 33~36 | 200 |

| 62 | 38EH | 1.22 | 12.2 | 923 | 11.6 | 2387 | 30 | 279~310 | 35~39 | 200 |

| 63 | 40EH | 1.25 | 12.5 | 947 | 11.9 | 2387 | 30 | 295~326 | 37~41 | 200 |

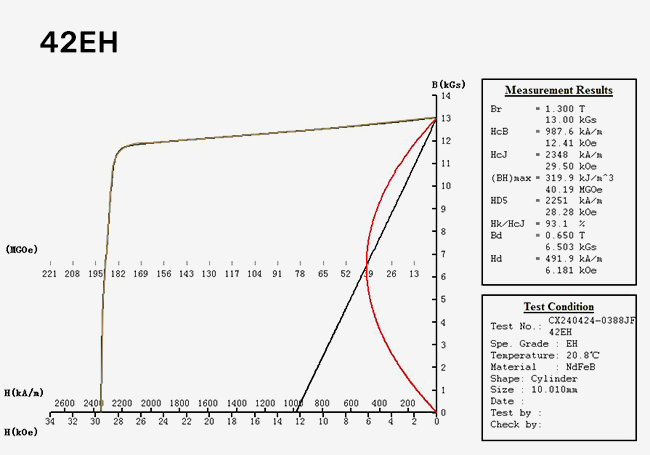

| 64 | 42EH | 1.28 | 12.8 | 971 | 12.2 | 2387 | 30 | 310~342 | 39~43 | 200 |

| 65 | 45EH | 1.33 | 13.3 | 995 | 12.5 | 2387 | 30 | 342~366 | 43~46 | 200 |

| 66 | 48EH | 1.37 | 13.7 | 1019 | 12.8 | 2387 | 30 | 358~390 | 45~49 | 200 |

| 67 | 28AH | 1.05 | 10.5 | 756 | 9.5 | 2786 | 35 | 207~231 | 26~29 | 220 |

| 68 | 30AH | 1.08 | 10.8 | 804 | 10.1 | 2786 | 35 | 223~247 | 28~31 | 220 |

| 69 | 33AH | 1.14 | 11.4 | 816 | 10.2 | 2786 | 35 | 247~271 | 31~34 | 220 |

| 70 | 35AH | 1.18 | 11.8 | 845 | 10.6 | 2786 | 35 | 263~287 | 33~36 | 220 |

| 71 | 38AH | 1.22 | 12.2 | 932 | 11.6 | 2627 | 33 | 279~310 | 35~39 | 220 |

| 72 | 40AH | 1.25 | 12.5 | 947 | 11.9 | 2627 | 33 | 295~326 | 37~41 | 220 |

| 73 | 42AH | 1.28 | 12.8 | 971 | 12.2 | 2627 | 33 | 310~342 | 39~43 | 220 |

Physical Properties of Sintered NdFeB

| Temp.Coeff. of Br (reversible temperature coefficient) |

-0.09~-0.11%℃ | Temp. Coeff. of He | -0.50~-0.60%℃ |

| Density | 7.4〜7.6 g/cm3 | Electrical Resistivity | 114 μΩ.cm |

| Vickers Hardness | 600 Hv | Flexural Strength | 25 Kg/mm |

| Tensile Strength | 8.0 Kg/mm3 | Coeff. of Thermal Expansion | 4x10-6/℃ |

| Specific Heat | 0.12 Kca/(kg,℃) | Thermal Conductivity | 7.7 Kca/(m.h.℃) |

| Young's Modulus (Young's Tensile Strength) | 1.6x1011 N/m3 | Rigidity | 0.64 N/m2 |

| Poisson's Ratio | 0.24 | Compressibility | 9.8x10-12m2/N |

| Curie Temperature | 310-340 ℃ | Relative Recoil Permeability prev | 1.05 |

Dimensional deviation (unit: mm)

| Shape | Schematic | Size(mm) | |

| Axial | Vertical | ||

| Block |  |

30<W<100;15<L<80;20<H<60 100≤W≤240;30<L<240;30<H<60 240<W<300;40<L<120;30<H<60 |

|

| Disk |  |

6≤D<8;20<H<32 8≤D<9.5;20<H<36 9.5≤D<32;20<H<44 32≤D<250;22<H<60 |

8≤D<17;20<H<32 17≤D<90;22<H<60 |

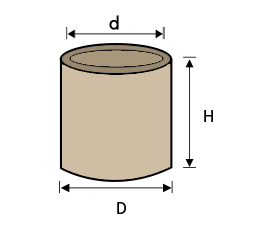

| Ring |  |

18≤D<32;20<H<35 32≤D<250;20<H<45 |

20≤D≤60 8≤(D-d)/2<15 25≤H≤40 |

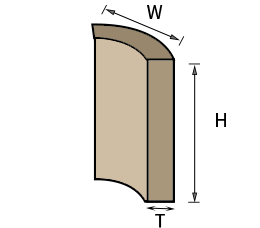

| Arc |  |

25≤W≤55; 15≤T≤40; 25≤H≤55; |

25≤W≤75 25≤T≤50 25≤H≤100 |

Dimensional deviation (unit: mm)

| Size | Allowable deviation of sintered surface | Allowable deviation of working surface | ||||

| Perpendicular to the pressing direction | Direction of suppression | Flat grinding | Internal and external round grinding | Wire cutting | slice | |

| ≤10 | ±0.25 | ±0.30 | ±0.04 | ±0.05 | ±0.06 | ±0.05 |

| 10~20 | ±0.40 | ±0.45 | ±0.05 | ±0.05 | ±0.08 | ±0.08 |

| 20~50 | ±0.60 | ±0.70 | ±0.06 | ±0.05 | ±0.10 | ±0.10 |

| 50~80 | ±1.00 | ±1.10 | ±0.08 | ±0.05 | ±0.10 | ±0.10 |

| 80~150 | ±1.00 | ±1.10 | ±1.15 | ±0.15 | ||

Shape deviation (unit: mm)

| Variation type | Variation type | Basic size(mm) | Deviation | |

| Parallelism | Working surface room | One-half of the tolerance value | ||

| Verticality | Between sintered surfaces | Random | 90°±1° | |

| Between machined surface and sintered surface | 90°±1° | |||

| Working surface room | 90°±0.15° | |||

| Concentricity | Between sintered surfaces | Outer diameter | ≤14 | ±0.35mm |

| 14~24 | ±0.60mm | |||

| 24~40 | ±0.80mm | |||

| 40~60 | ±1.100mm | |||

| 60~80 | ±1.150mm | |||

EN

EN English

English 中文简体

中文简体 русский

русский Deutsch

Deutsch 日本語

日本語 한국어

한국어