Jinlun Magnet Promotes Sustainable Development

-

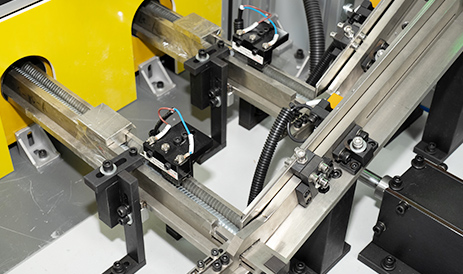

Advanced & Eco-friendly Equipment

Advanced & Eco-friendly Equipment

We have an internationally advanced mechanized permanent magnet production line, production technology, and comply with environmental protection standards.

-

Reduce Resource Waste

Reduce Resource Waste

Pursue energy saving and low carbon, adopt energy-saving technologies and processes, and reduce energy consumption and carbon emissions in the production process.

-

Green Development & Quality

Green Development & Quality

We had awarded as a Four-Star green factory and a key-cultivation enterprise of Ningbo manufacturing industry, and continuously empower the green development of the magnet industry.

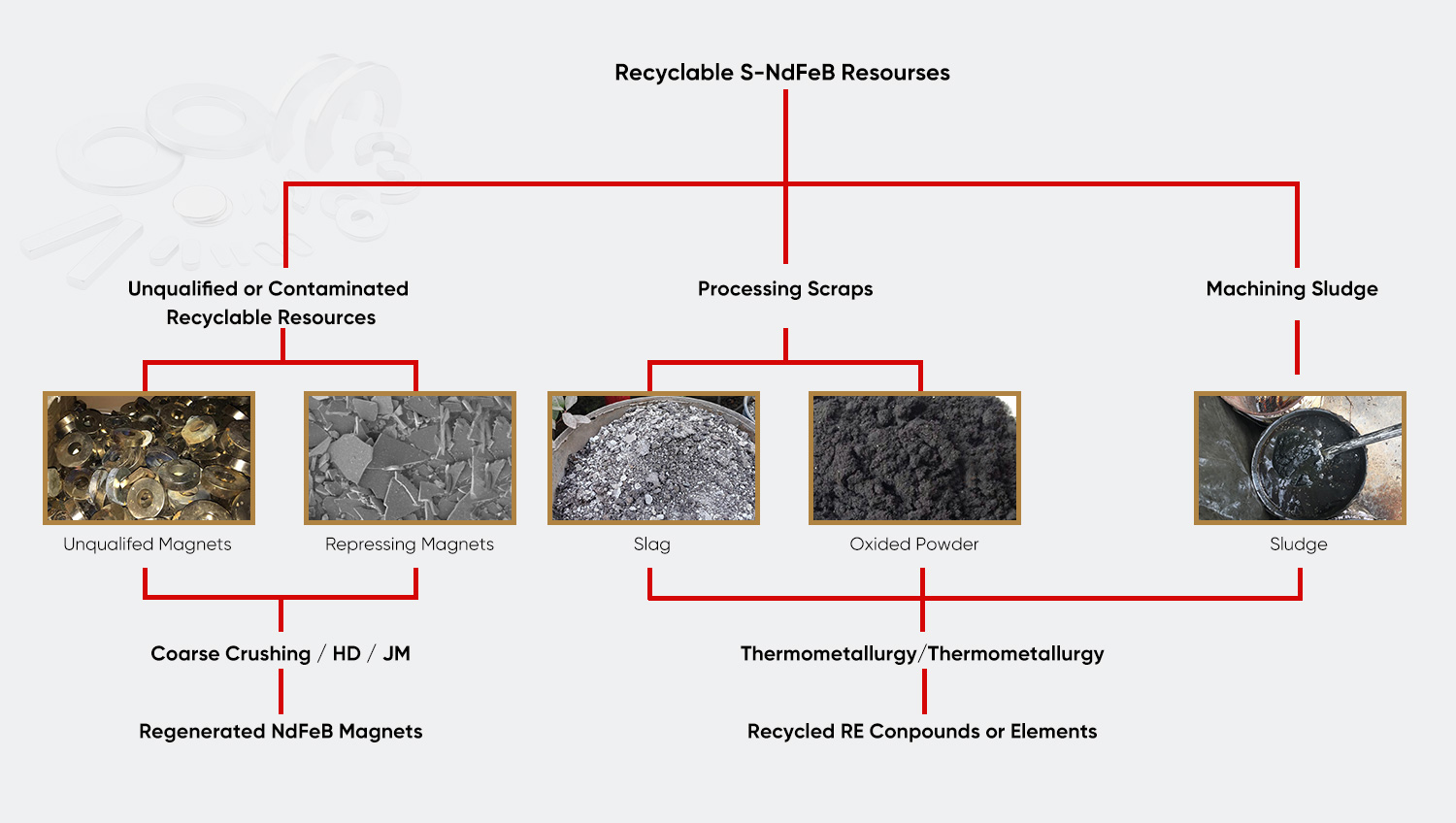

Recyclable Mode

In some cases, the raw-material can be recycled, achieving the recycling of resources.

Safe Raw Materials

Indirectly reduce green house gas emissions by reducing the burning of fossil fuels and improving energy efficiency.

National Green Certificate

Environmental technology quality management and other environmental protection related certifications.

|

Top-level Strategic Design |

Full Life Cycle Assessment |

Policy Compliance Integration |

|

▶ Energy Cascade Utilization System Integrate waste heat recovery, photovoltaic-energy storage microgrid, and intelligent lighting (light sensing + human body sensing), and reduce comprehensive energy consumption by more than 20%.

▶ Closed-loop Water Treatment System Deploy a membrane bioreactor (MBR) and reclaimed water reuse device to realize the recycling of cutting fluid and cleaning wastewater, reducing water resource consumption by 30%.

▶ Cooperation Between Carbon Capture and Greening Install a vertical greening system on the roof and facade of the factory building, combined with carbon dioxide adsorption materials (such as MOFs), with an annual carbon sink capacity of 100 tons and PM2.5 filtration efficiency exceeding 30%. |

|

|

Water isostatic pressing technology In the isostatic pressing process for magnetic material forming, water is used as the medium, eliminating oil consumption and leakage pollution while conserving non-renewable resources. |

Cyanide-free electroplating process In the surface treatment of magnetic materials, an environmentally friendly cyanide-free electroplating solution eliminates the emission of highly toxic substances and reduces the difficulty of wastewater treatment by 20%-50%. |

|

Low-energy sintering technology Adopting advanced sintering technology and equipment can reduce energy consumption by more than 10% compared with traditional sintering. |

Solvent recovery system For organic solvents (such as acetone and ethanol) used in the production process, it is equipped with condensation recovery devices and activated carbon adsorption tower equipment. |

|

Magnetic Mud Recycling The magnetic mud produced by the magnetic material grinding process is used to extract rare-earth elements through a special process, and the remaining iron powder can be used as a metallurgical raw material, achieving a waste resource utilization rate of over 90%. |

Waste Cutting Fluid Treatment Ultrafiltration membrane separation + advanced oxidation combined technology is used to separate the oil and water in the waste cutting fluid. The treated water quality meets the GB 8978-1996 1st level emission standard, and the oil phase can be refined and reused. |

Waste Mold Recycling System Establish a mold full life cycle management system to perform laser cladding repair or powder metallurgy regeneration on scrapped carbide molds, increasing the mold material recycling rate to more than 60%. |

|

Efficient Energy-saving Equipment Upgrade |

Clean Energy Alternatives |

Waste Recycling Technology |

|

● Upstream raw material green procurement Cooperate with mining companies to establish a green supply chain, give priority to purchasing rare-earth raw materials that have been certified for environmental protection, and promote suppliers to adopt low-carbon mining technology to reduce the carbon footprint of the entire industry chain. ● Downstream high-value-added product development Expand the application of magnetic materials in green fields such as new energy vehicles and wind power, and develop high-performance permanent magnets to meet the market demand for high-performance and long-life products. ● Horizontal collaborative cooperation Jointly build a magnetic material innovation center with universities and research institutions, integrate industrial chain resources, and promote integrated solutions from material research and development to terminal applications. |

|

|

◆ Phase-by-phase emission reduction targets Set a phased target of reducing carbon emissions by 40% in 2030 compared with 2025, relying on the implementation of strategies such as process optimization and energy structure adjustment, and ultimately achieve carbon neutrality in the entire value chain by 2050 to comprehensively promote green and low-carbon transformation.

◆ International standard certification

Actively apply for ISO 14064 greenhouse gas management system certification, and actively participate in the International Carbon Disclosure Project (CDP) to increase the global market's recognition of our sustainable development efforts by regularly publishing emission reduction results.

◆ Carbon offset mechanism implementation

Committed to investing in forestry carbon sinks or renewable energy projects to offset inevitable carbon emissions. At the same time, explore the path to participate in the carbon trading market and build a sustainable, carbon-neutral business model. |

|

EN

EN English

English 中文简体

中文简体 русский

русский Deutsch

Deutsch 日本語

日本語 한국어

한국어